Arc surface spreading flow film sorting machine

A kind of sorting machine and curved surface technology, applied in the direction of solid separation, wet separation, chemical instruments and methods, etc., can solve the problems of complex equipment movement, difficult multi-layer structure setting, limited space for processing capacity improvement, etc., and achieve design Sophisticated, shortened sorting time, compact structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the specific implementation has been clearly and completely described in the technical solution, and will not be repeated.

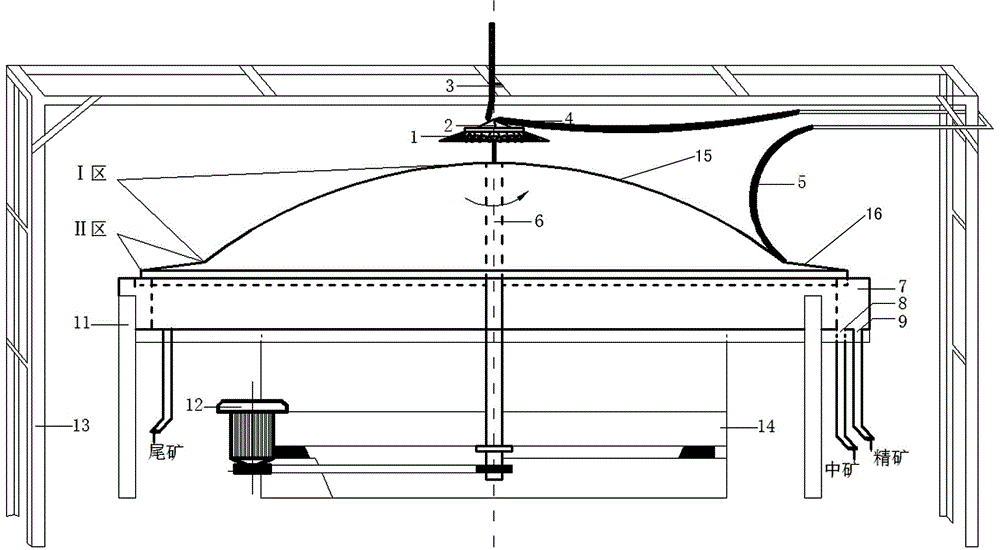

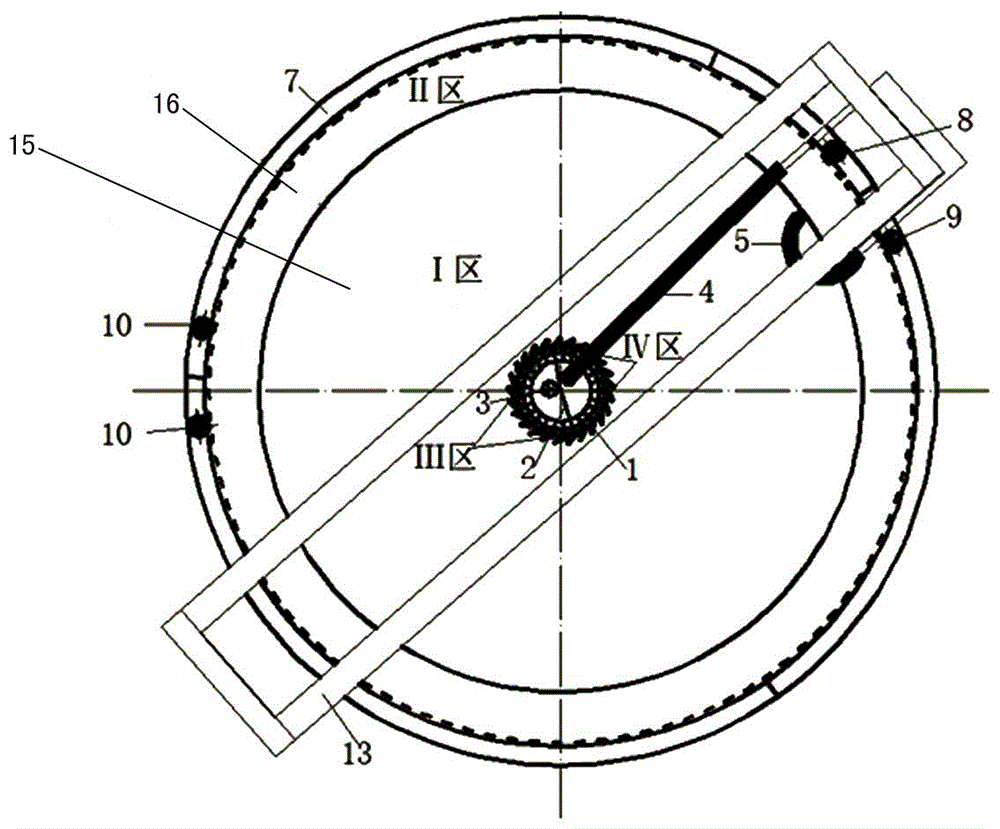

[0036] see figure 1 , 2 , 3, 4. The whole equipment is mainly composed of a rotating sorting disc 15 driven by a driving device, an ore feeding and water supply device, and an ore connecting and discharging device. The upper surface of the sorting disc 15 is a spherical arc with a curvature radius of 0.58-2.27m surface, the outer edge of the arc surface of the sphere is connected with an annular slope 16 which is 3 to 8° from the horizontal plane, and the flushing water pipe 5 in the same direction of rotation is installed on the annular slope 16, and under the sorting disc at the flushing water pipe 15 The ore-connecting tank 7 is set at this interval for the middle ore discharge port 9, the concentrated ore middle ore ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com