Desulfurization wet flue gas combined deep purification device

A deep purification device and combined technology, which can be used in combined devices, gas treatment, chemical instruments and methods, etc., can solve the problems of short service life and poor purification effect of mist eliminators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

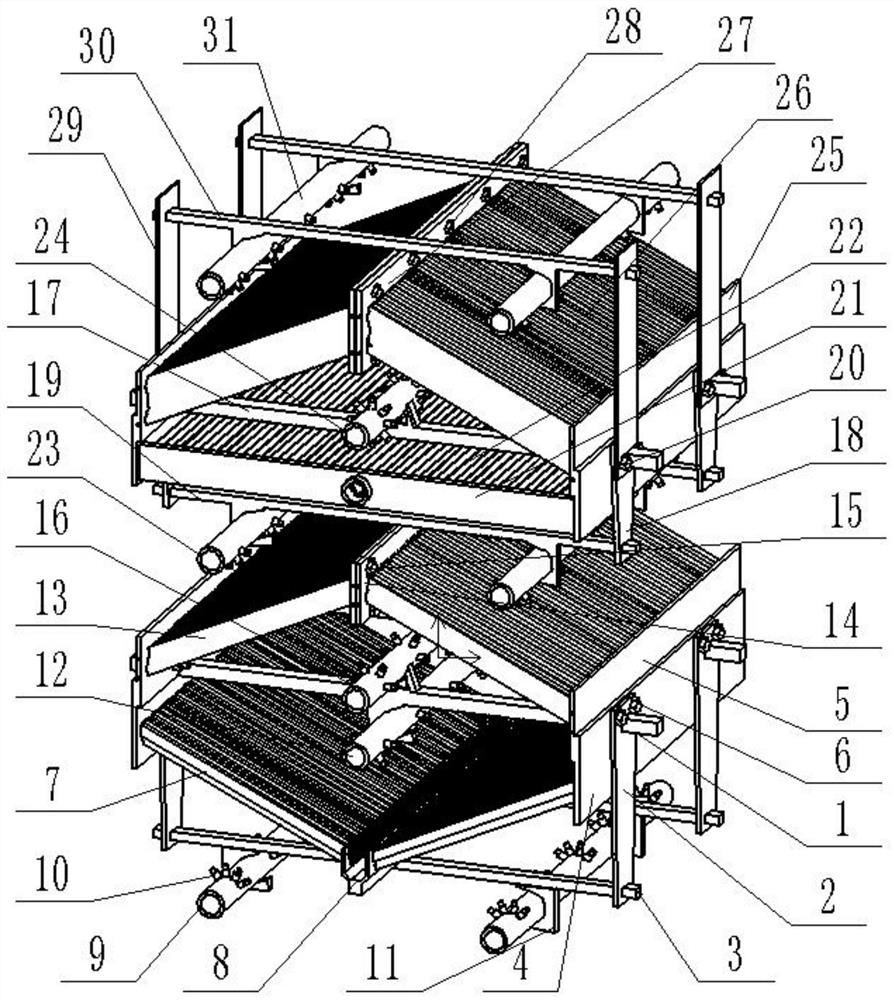

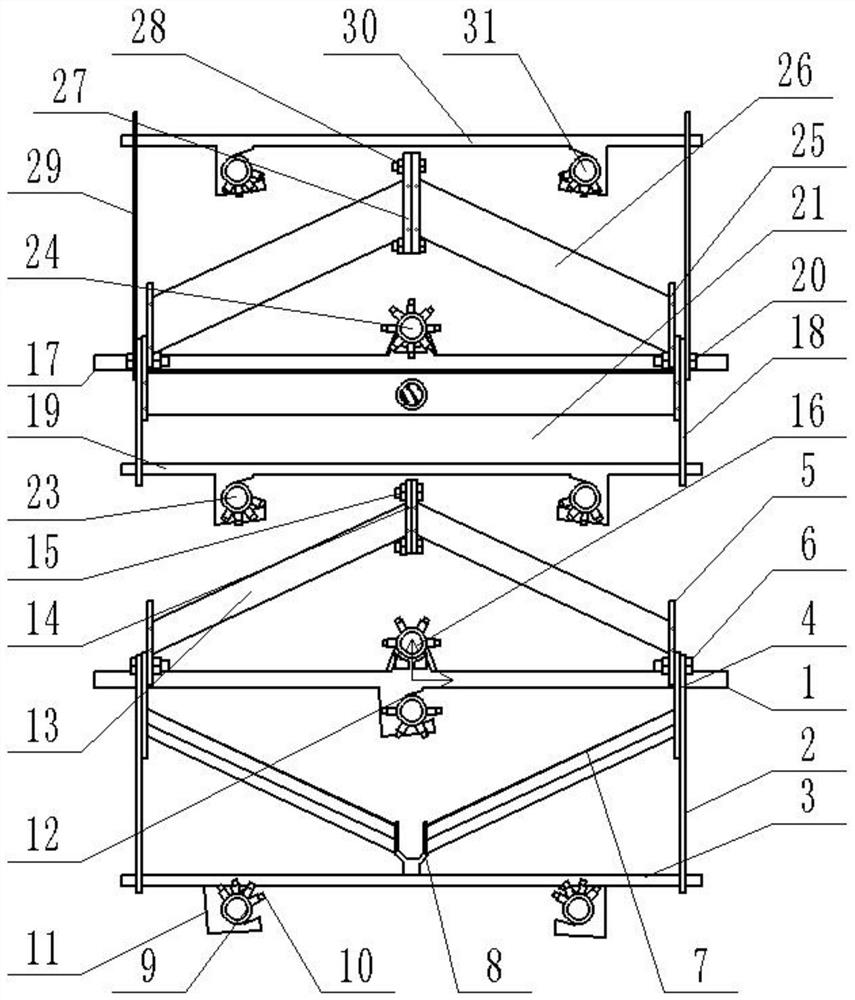

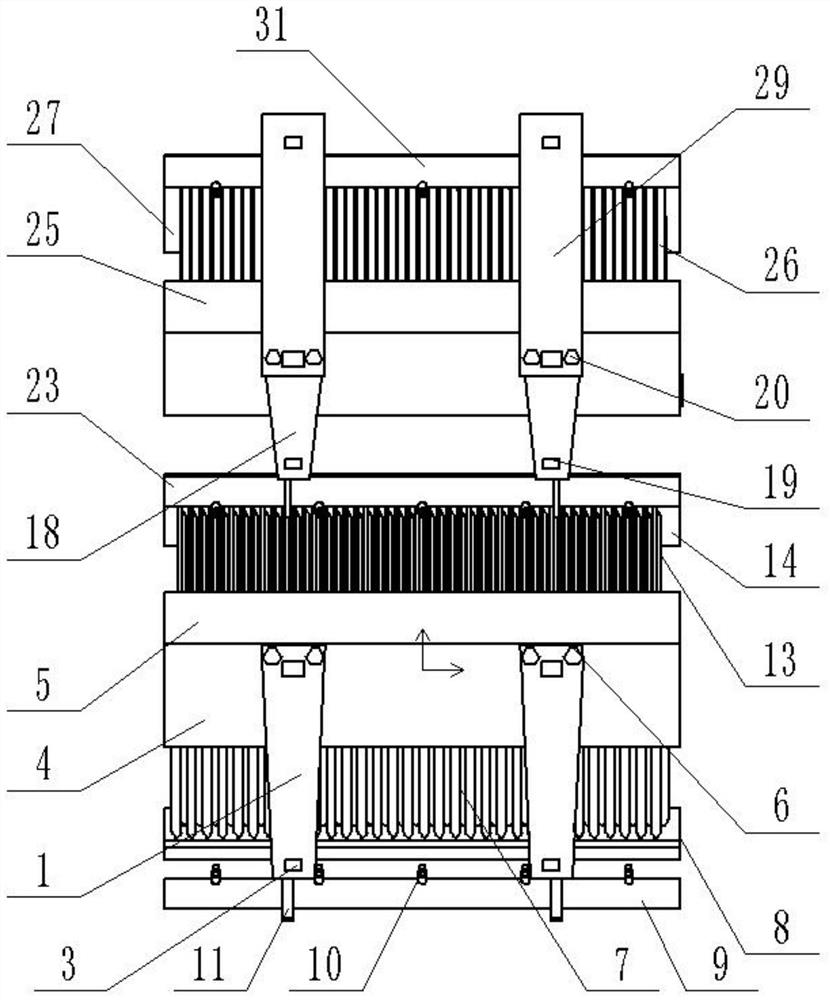

[0028] according to Figure 1 to Figure 7 As shown in the figure, the combined deep purification device for desulfurization and wet flue gas includes, from bottom to top, a Venturi negative suction demist layer, a high-efficiency demister layer, a condensation demister layer and an ultra-fine demister layer. The left and right sides of the upper end of the mist layer are respectively provided with left and right venturi negative suction demisting layer side plates 4, and the left and right sides of the lower end of the high-efficiency mist removing layer are respectively provided with left and right high-efficiency demisting layer lower side plates 5. A beam I1 is provided between the defogging layer and the high-efficiency defogging layer, and through holes are provided at the corresponding positions of the side plates 4 of the left and right venturi negative suction defogging layers and the beam I, and the left and right ends of the beam I1 pass through the left and right ven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com