Industrial welding and cutting gas with environmental-protective and energy-saving functions

An environment-friendly, energy-saving, industrial gas technology, applied in the petroleum industry, fuel, gas fuel, etc., can solve problems such as harsh working conditions, high energy consumption, flammable acetylene gas, etc., to expand the scope of use, significant economic benefits, and not easy to explode Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] An environmentally friendly and energy-saving welding and cutting industrial gas, which contains liquefied petroleum gas and accelerators, is a hydrocarbon industrial gas that can be used for both cutting and welding. It is a mixed solution composed of 98.5-99.5wt% of liquefied petroleum gas and 0.5-1.5wt% of accelerator additive based on the total weight of industrial gas.

[0011] The liquefied petroleum gas is commercially available containing C 3 and C 4 , does not contain methylsulfuric acid and methylmercaptan; the accelerator includes 0.1-0.4wt% of 2-methoxypropane by industrial gas gross weight, 0.07-0.13wt% of methylcyclopentadiene, dipentamyl 0.1 to 0.3 wt% of alkene, 0.2 to 0.6 wt% of dicyclopentadiene, and 0.03 to 0.07 wt% of dicyclopentavinyl iron;

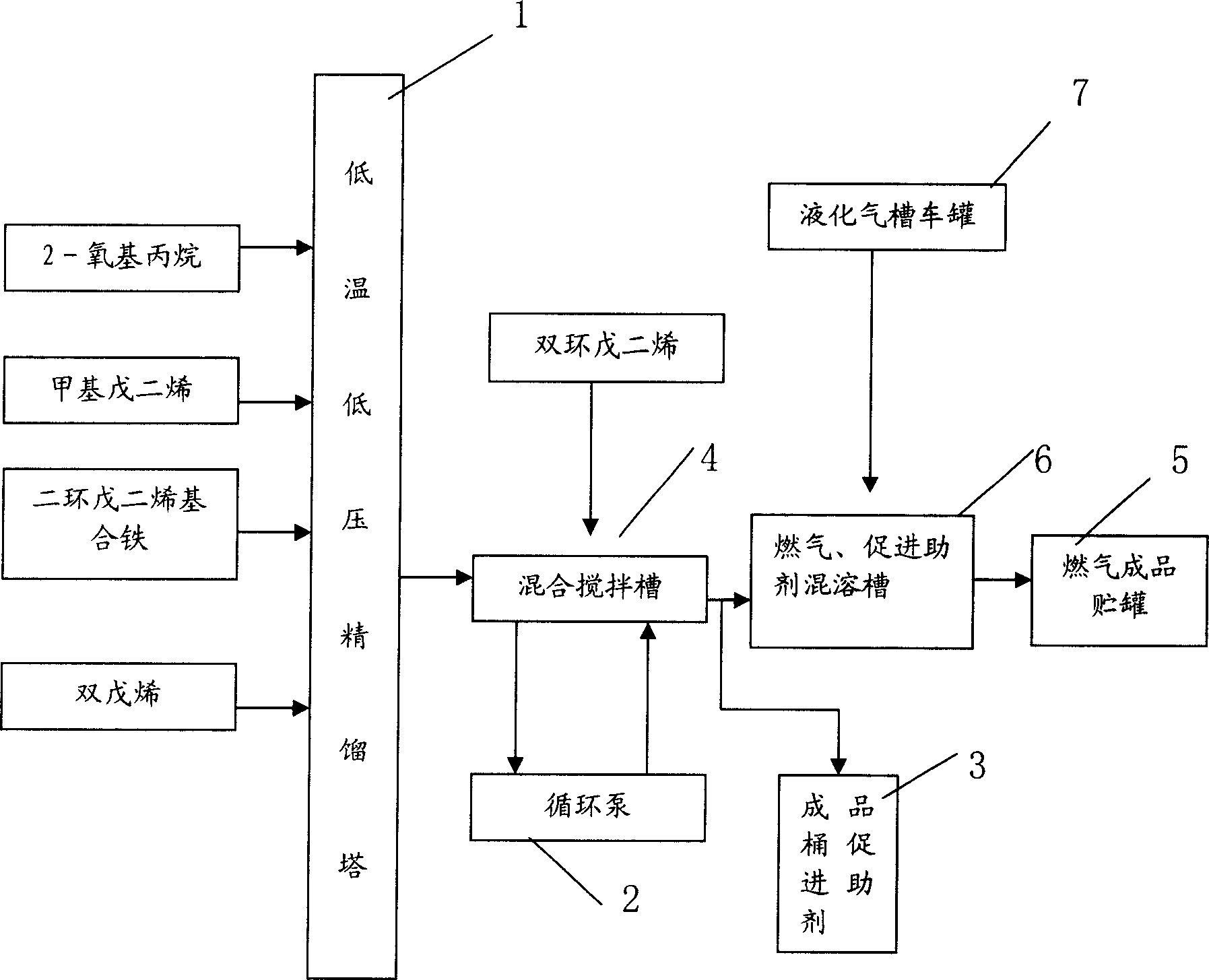

[0012] The preparation process of industrial fuel gas of the present invention is as shown in Figure 1, first 0.3wt% 2-methoxypropane, 0.08wt% methylcyclopentadiene, 0.04wt% dicyclopentaethenyl iron alloy of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com