Laminated semiconductor substrate and process for producing the same

一种制造方法、衬底的技术,应用在半导体/固态器件制造、半导体器件、电固体器件等方向,能够解决活性层金属污染、长处理时间、工艺复杂等问题,达到提高生产率、降低成本、缩短处理时间的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

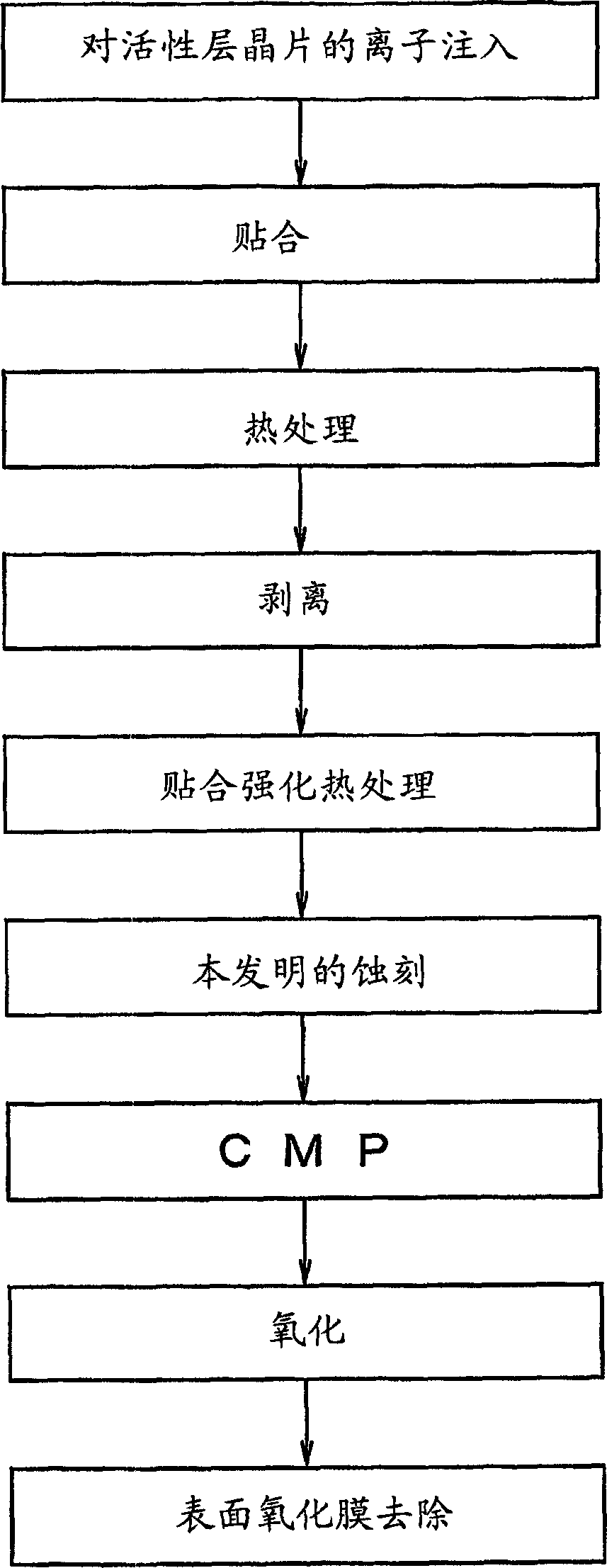

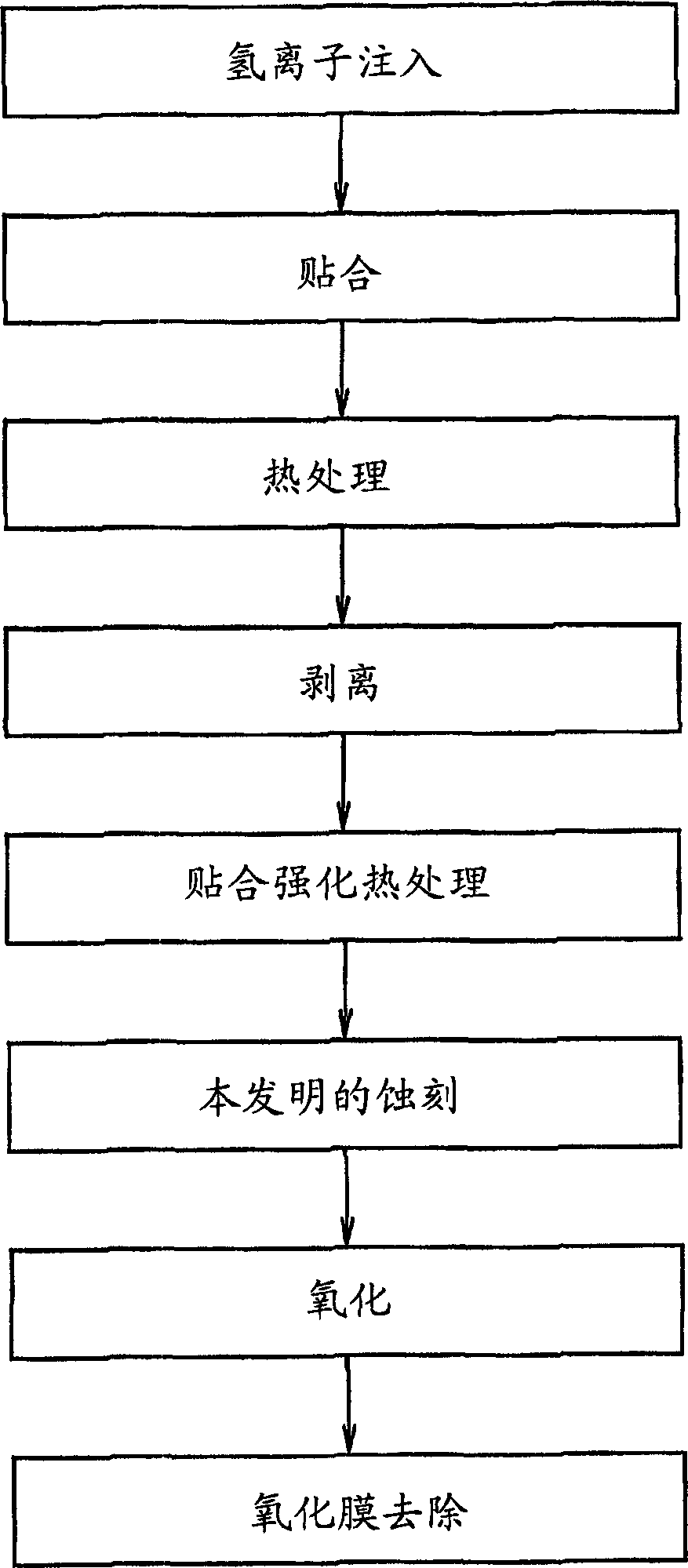

[0093] Embodiment 2 is an example as follows: In the second embodiment, the same procedure as that of the first embodiment is adopted, through hydrogen ion implantation to the wafer for the active layer, bonding of the wafer for the active layer and the wafer for the support substrate, and bonding of the wafer for the support substrate. The peeling heat treatment for forming bubbles of the bonded wafer, the peeling of the ion-implanted part of the wafer for the active layer, the bonding heat treatment for improving the bonding strength of the bonded wafer, etc., use the SC-1 cleaning solution to etch only the active layer surface. specified amount. Afterwards, CMP treatment, oxidation and oxide film removal are sequentially performed on the surface of the active layer.

[0094] At this time, the surface roughness of the active layer immediately after peeling was 6.17 nm (Rms).

[0095] The above-mentioned SC-1 etching was performed for 135 minutes using the same liquid compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com