Optical head device and method of manufacturing optical head device

An optical head and laser technology, applied in the manufacture of optical heads, optical recording heads, etc., can solve problems such as wavelength variation, deformation, and influence of optical system parts of emitted light, and achieve the effects of suppressing characteristic changes, improving durability, and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Next, an optical head device to which the present invention is applied will be described with reference to the accompanying drawings.

[0031] (the whole frame)

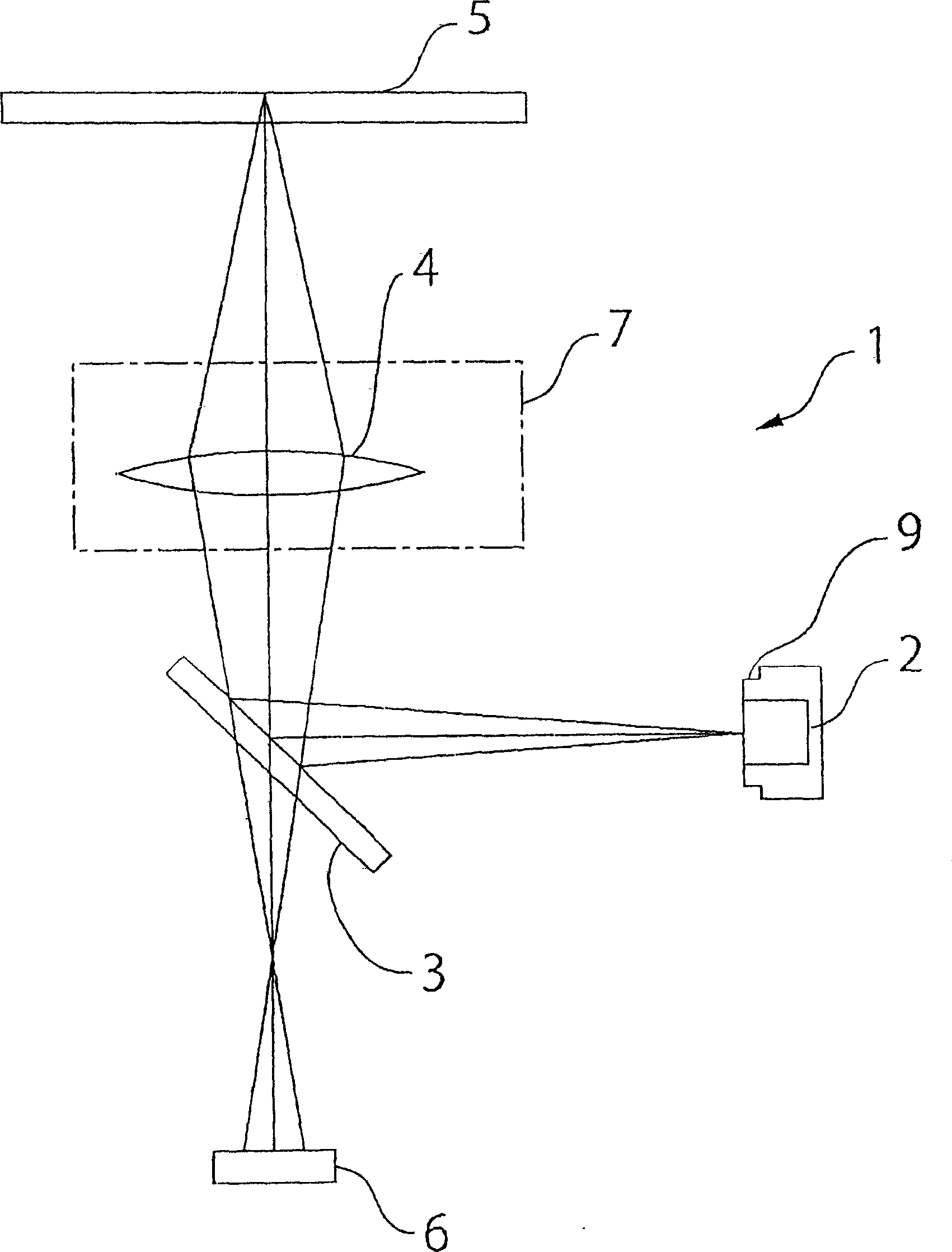

[0032] figure 1 It is a schematic configuration diagram showing an example of an optical head device to which the present invention is applied.

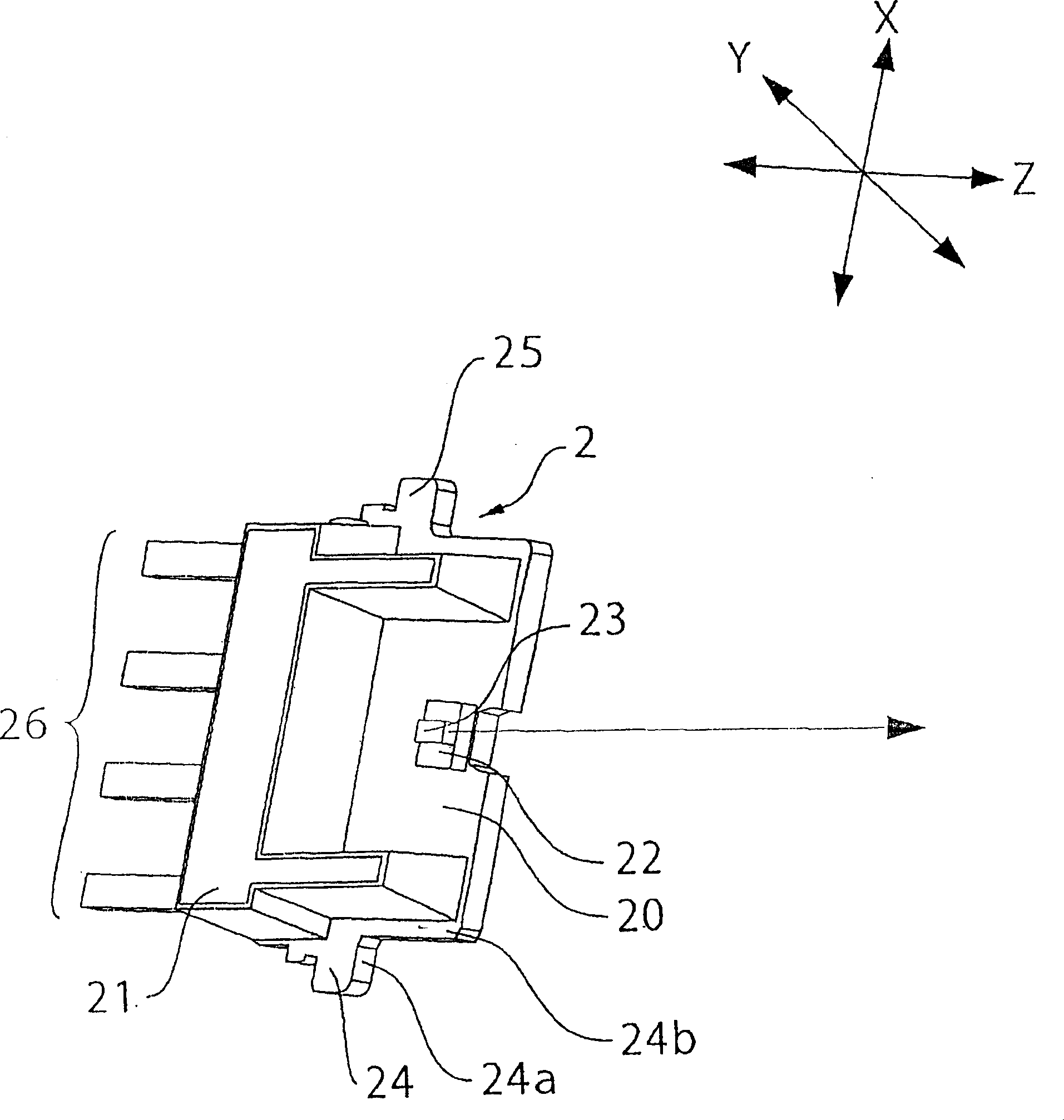

[0033] Such as figure 1 As shown, the optical head device 1 is a device for recording and reproducing information on an optical recording medium 5 such as a CD or DVD, and has: a laser light emitting element 2; Lens 3; the objective lens 4 that focuses the laser light reflected by the half mirror 3 on the optical recording medium 5; the photodetector 6 that receives the return light reflected by the optical recording medium 5 and passes through the objective lens 4 and the half mirror 3, these optical parts is mounted on base 10 (see Figure 7 )superior. In addition, an objective lens driving mechanism 7 for adjusting the position of the objective lens 4 in the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com