Self-adoptive efficient sounding method and apparatus of electro-sounding apparatus

A sound-generating device and self-adaptive technology, applied in the direction of sound-generating devices, instruments, etc., can solve the problems of affecting the sound level, the difference between the frequency of the circuit stabilization frequency and the natural vibration frequency of the machine, and the frequency mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

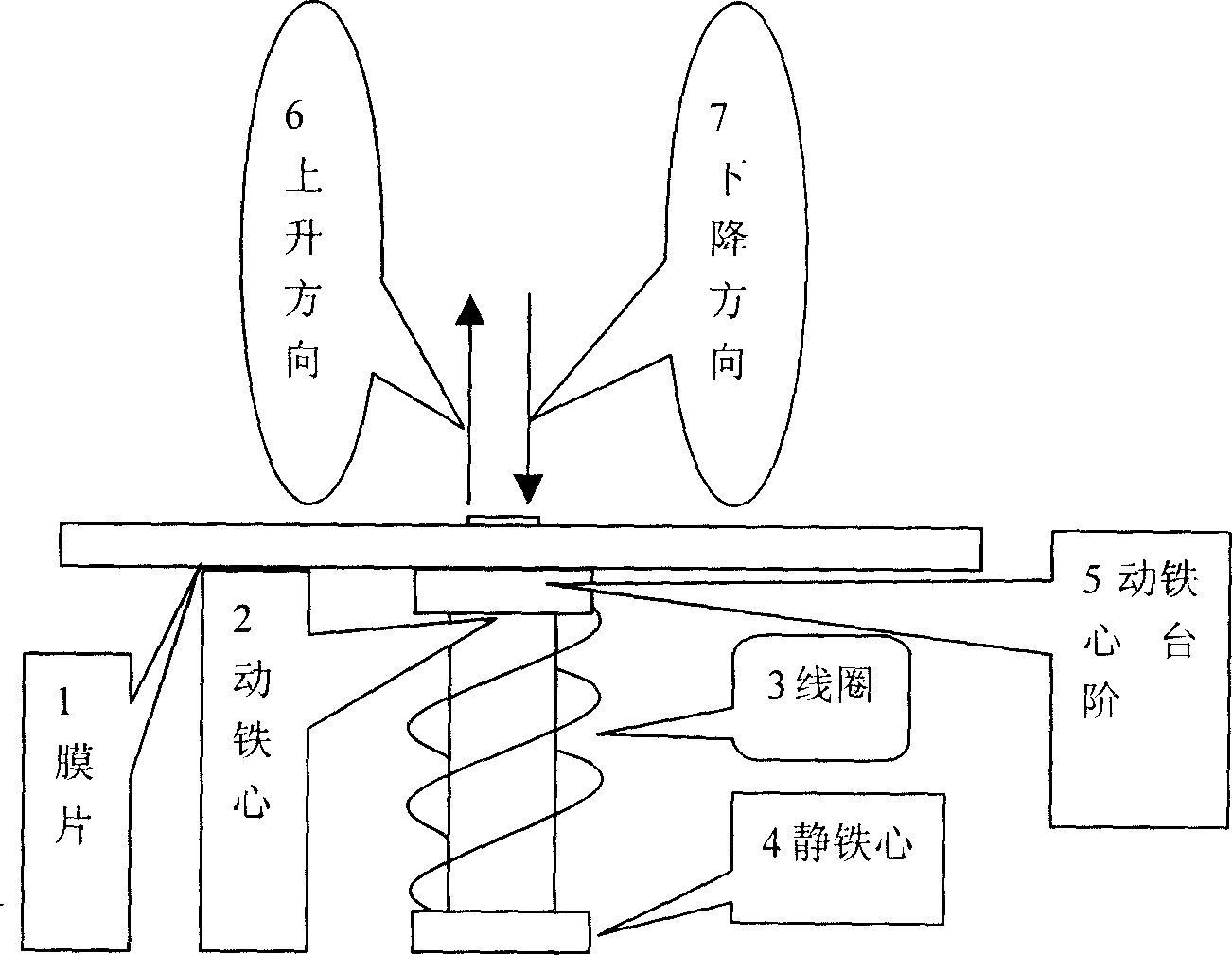

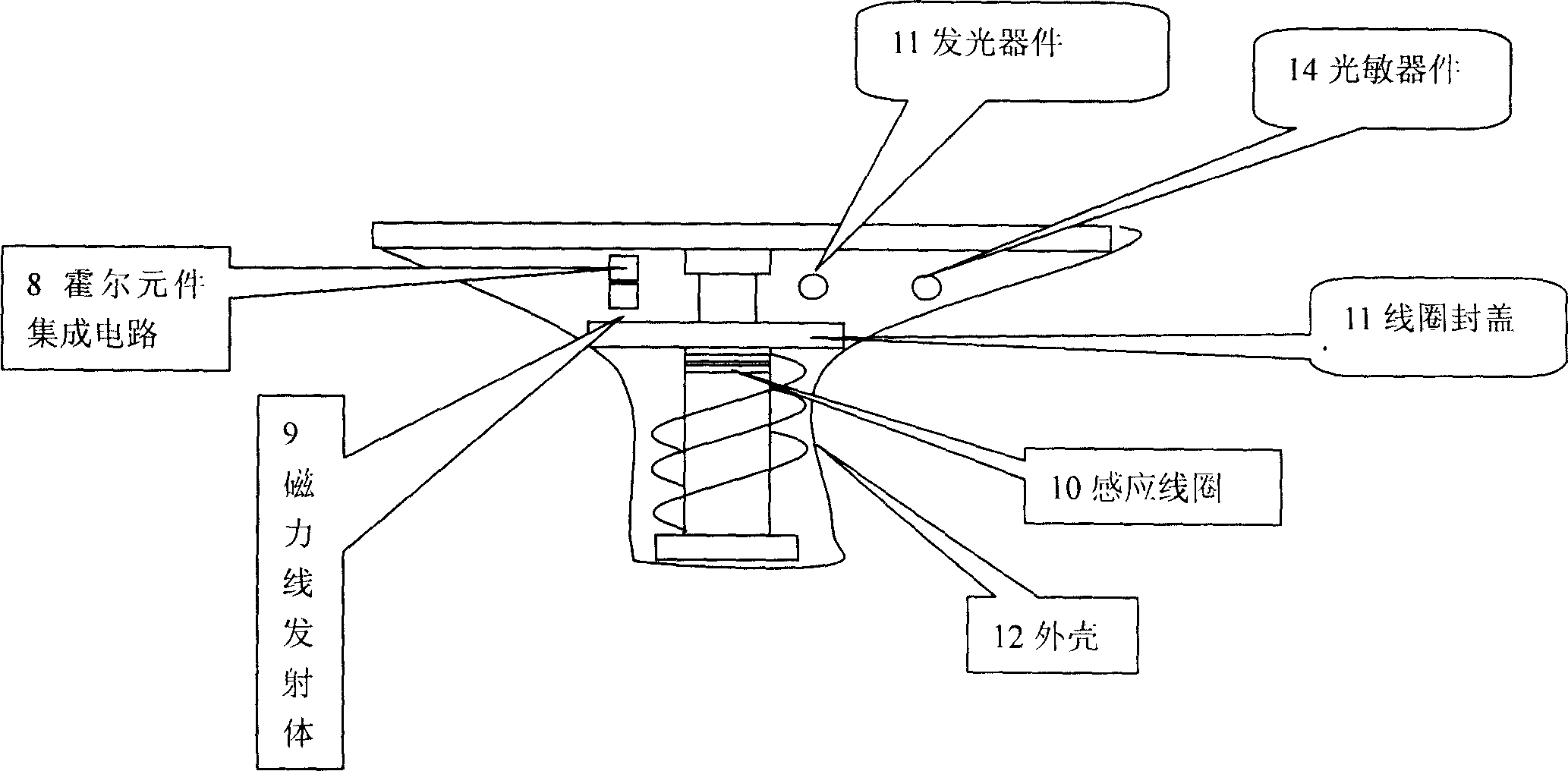

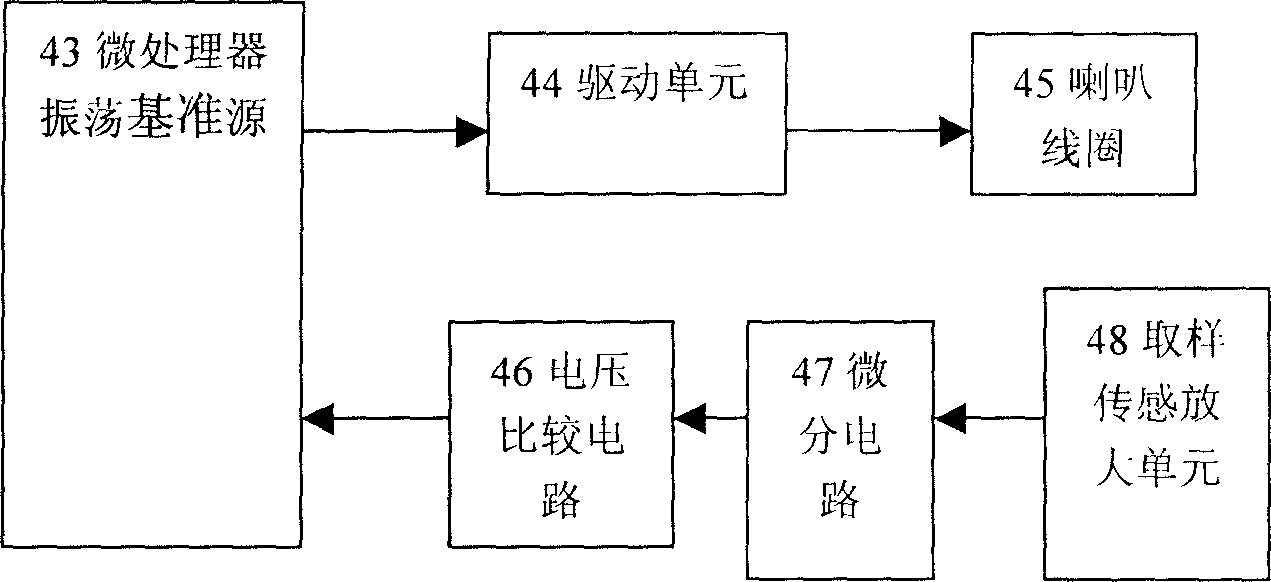

[0087] Example 1: Vibration of the Hall sensor diaphragm (such as figure 2 8 Hall element integrated circuits, 9 magnetic force line emitters), the subsequent processing of the signal is as follows image 3 As shown, we first obtain the natural frequency by the method of residual vibration test; Figure 5 For the circuit, in a relatively small range such as 5Hz, the accuracy is 1Hz; in the range of 65% to 75% energization rate, the accuracy is 1%. The frequency and energization rate are finally determined by adjusting while working.

[0088] The whole process: speaker power-initialization of microprocessor and each unit-test-adjustment-control-speaker power-off end.

example 2

[0089] Example 2: Sensing with an induction coil, such as figure 2 of 10 induction coils, whose signals are processed as Figure 4 (You can also choose Figure 5 ), first obtain the natural vibration frequency by the method of residual vibration test, and then adjust the energization rate by the flat-bottom method of energization rate adjustment.

example 3

[0090] Example 3: Take the style of direct coil as Figure 4 The circuit uses the method of residual vibration test to obtain the natural frequency, and then uses the direct power supply voltage to obtain the pattern such as Figure 4 The energization rate is adjusted by the flat-bottom method of energization rate adjustment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com