Gas auxiliary injection moulding apparatus and its control method

An injection molding, gas-assisted technology used in coatings, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

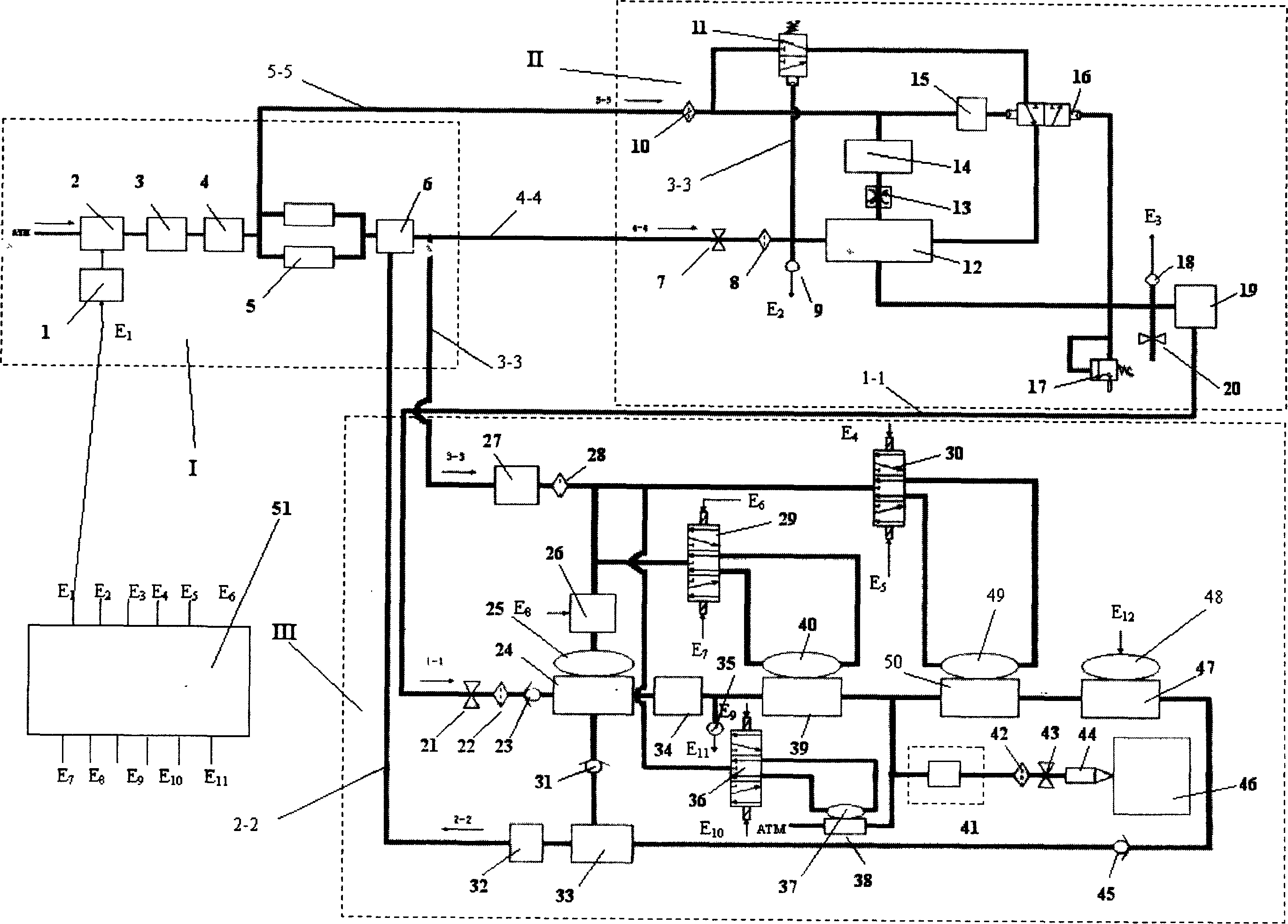

[0009] Concrete scheme of the present invention is as follows:

[0010] The high-pressure gas path in the nitrogen pressure control part is controlled by the gas pressure of the low-pressure gas path, and the central controller of the electronic control system is responsible for controlling the adjustment of the gas pressure in the low-pressure gas path, so as to realize the precise control of the nitrogen pressure in the high-pressure gas path.

[0011] 1. The pneumatic switching valve 28 can be opened quickly, so that the injected nitrogen can quickly reach the set pressure in the gas path, break through the solidified layer on the surface of the melt, and reduce the fluctuation of gas pressure in the gas path;

[0012] 2. The pressure regulating valve 24, the pressure sensor 27 and the electronic control system 50 constitute a nitrogen pressure closed-loop control loop. The feedback signal of the pressure sensor 27 is processed by the electronic control system 50 and then se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com