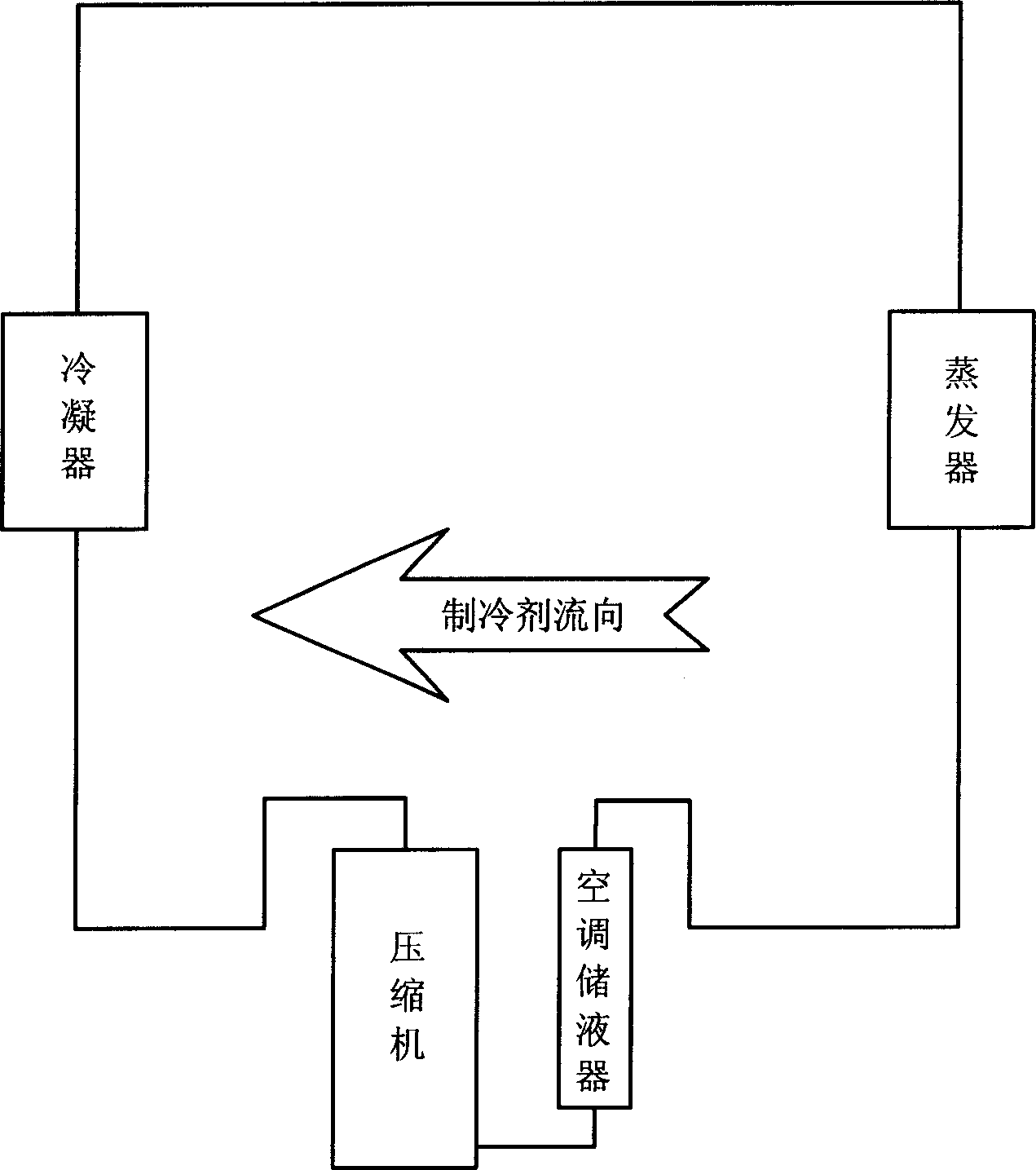

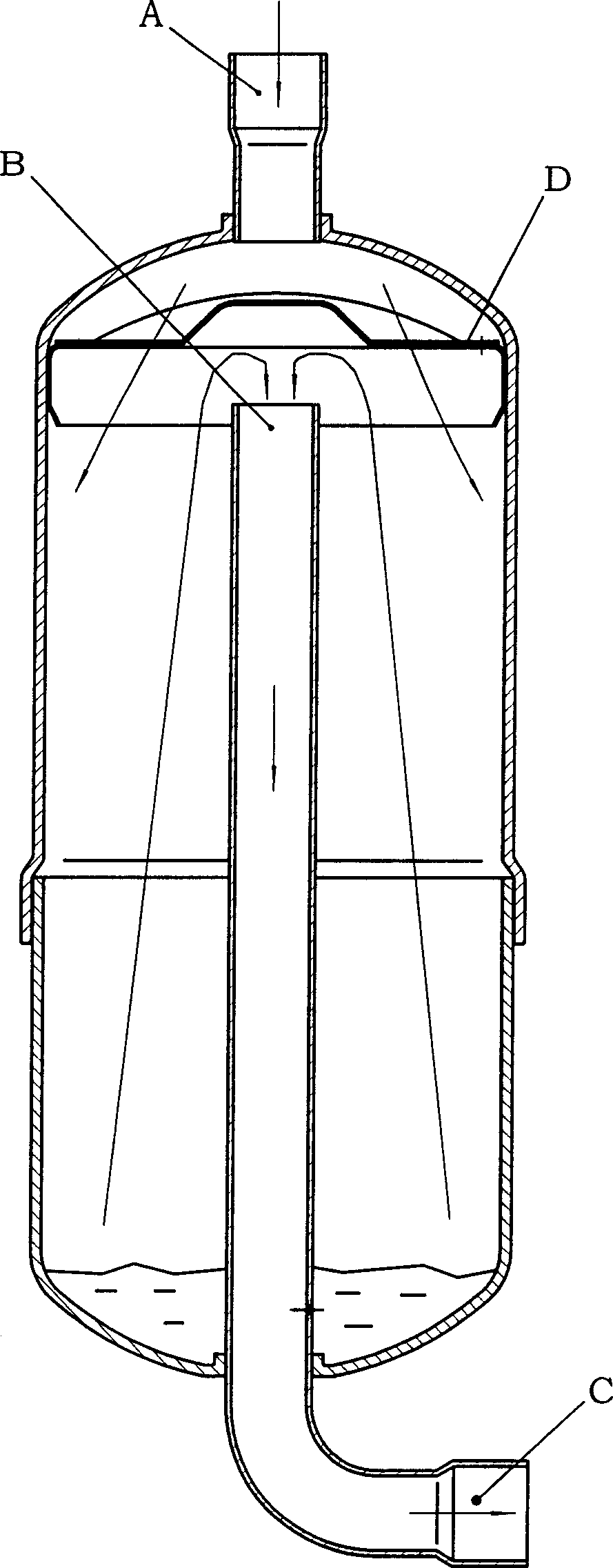

Liquid storing device for storing refrigrant in device

A liquid storage device and body technology, which is applied in the welding structure field of the liquid outlet pipe of the air-conditioning liquid storage device, can solve the problems of affecting the quality of the air-conditioning liquid storage device, high energy consumption, cracks, etc., and achieves simple structure and improved welding Process, the effect of reducing welding energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

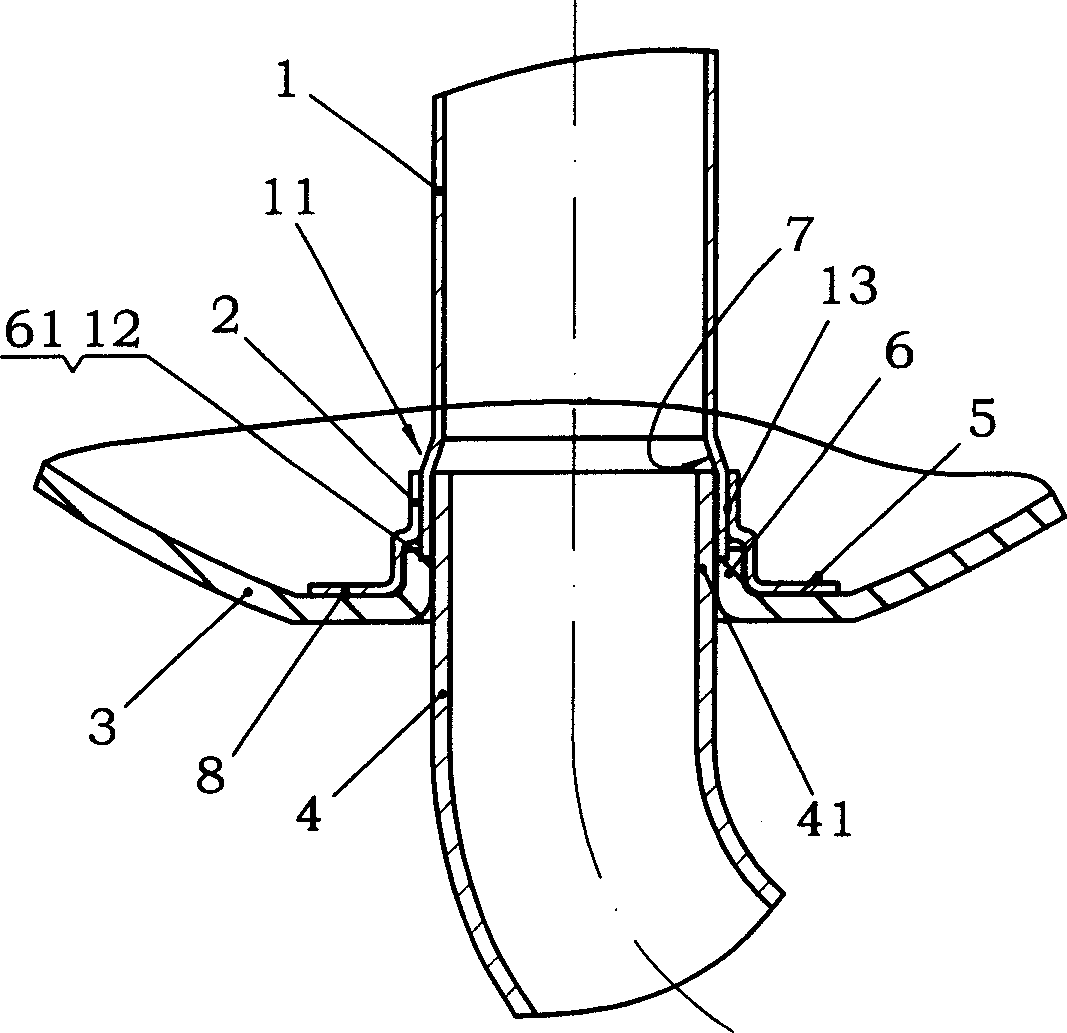

[0033] Such as image 3 As shown, a tubular flange 6 extending axially toward the inside of the body is provided at the center of the lower end of the body 3 , and a step 61 is provided at the upper end of the tubular flange 6 , and an iron thin-walled sleeve is placed on the tubular flange 6 Adapter seat 2, and its welding edge 8 is welded on the inner plane 5 of the body by bump welding, and the inner iron pipe 1 that has been flared is spot-welded on the adapter seat 2 through the outer wall 13 of its flared part 11 on the inner wall of the inner iron pipe, so as to realize the fixing of the inner iron pipe, and there is a step 7 near the tubular flange 6; the adapter seat 2 is set on the tubular flange 6 and welded with the body, so that the lower end of the inner iron pipe 12 interferes with the step 61 at the upper end of the tubular flange 6; the upper part 41 of the outer copper tube is inserted along the tubular flange, abuts against the step 7 of the flared part and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com