Plain end screw pipe and processing method thereof

A processing method and spiral technology, applied in the direction of pipeline connection layout, pipes, rigid pipes, etc., can solve the problems of low overall strength and rigidity, small connection area, water leakage at the interface, etc., to reduce construction machinery and equipment, simple connection process, The effect of improving installation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

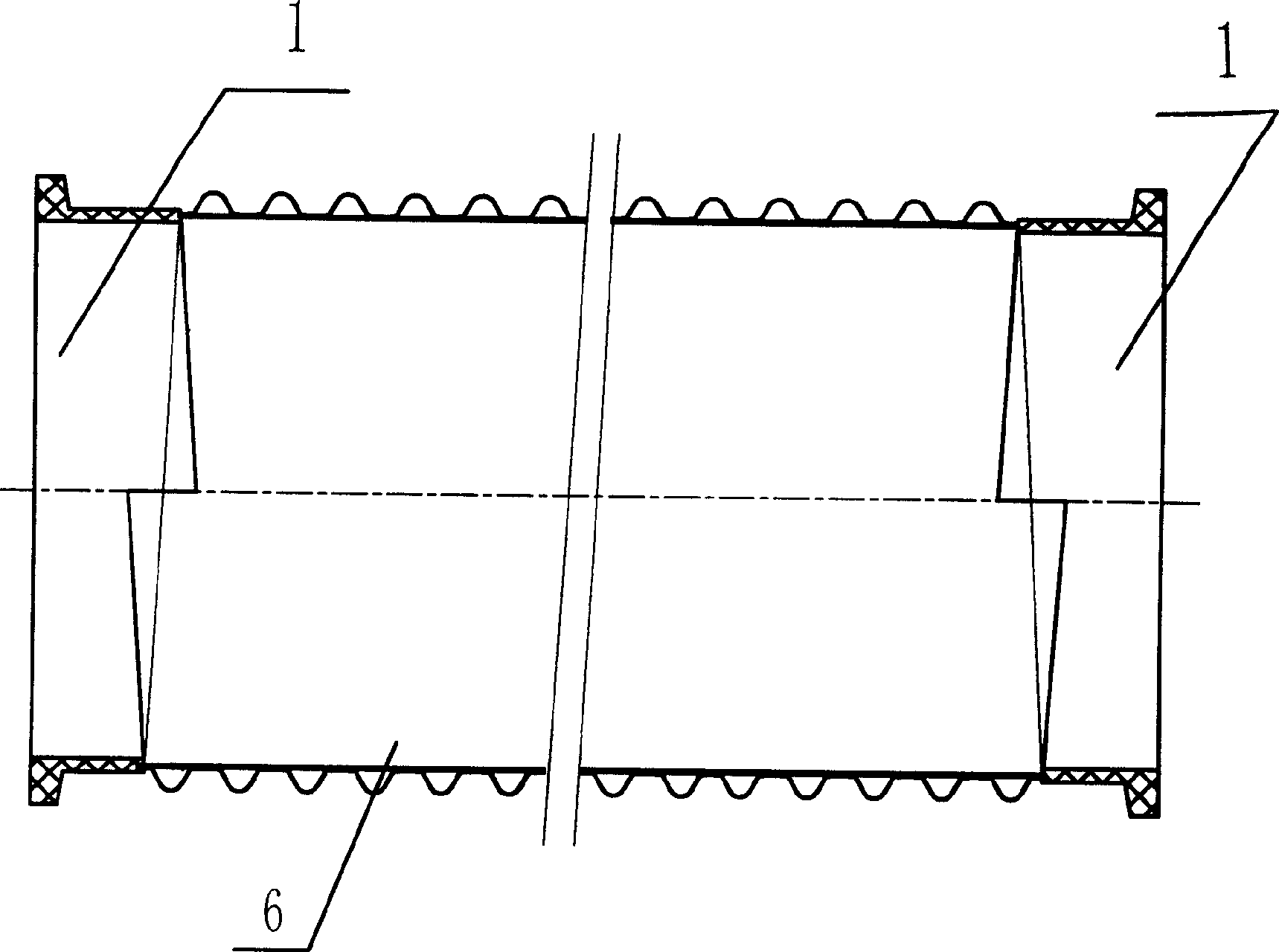

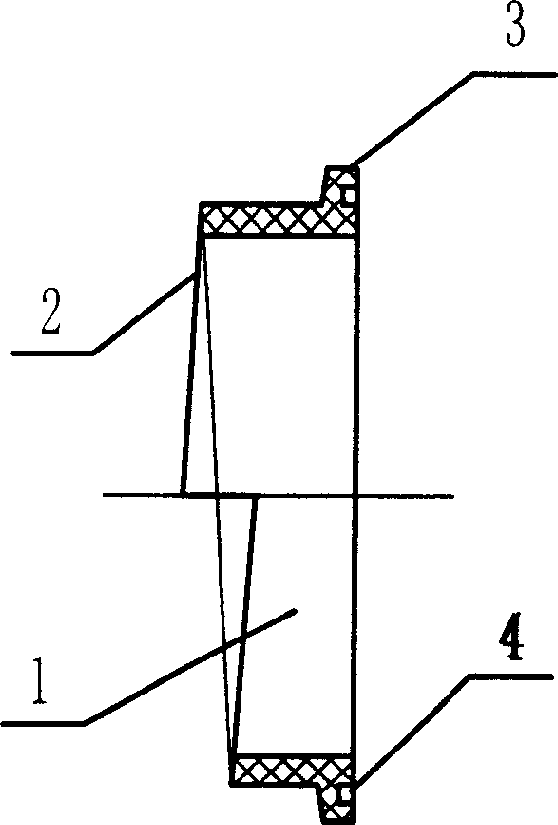

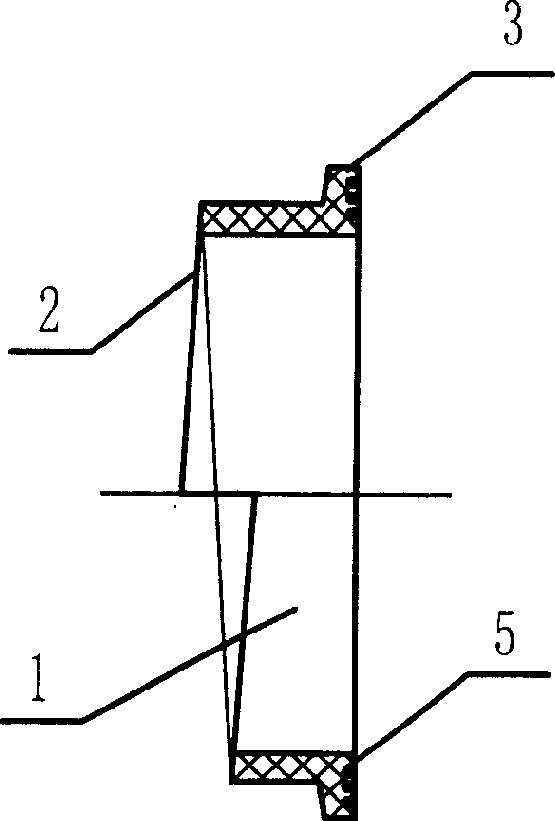

[0021] The present invention is mainly composed of a spiral pipe body 6, a spiral port connection member 1 welded and fixed on the spiral ports at one or both ends of the spiral pipe body 6, etc., one end of the spiral port connection member 1 is a spiral port 2, and the other end is a flat port , through the spiral port heater, the spiral port 2 of the spiral port connecting member 1 and the spiral port of the spiral pipe body 6 are heated and melted, and the two spiral ports are welded together under a certain pressure to form a whole, so that the spiral The screw port of the pipe body 6 is converted into a flat port, so as to realize the flat port connection between the pipes.

[0022] The spiral port connection member 1 is first made of a cylindrical tube 7 by extrusion winding, injection molding, pressing and other processes from plastic materials, and then the cylindrical tube 7 is cut into two symmetrical sections by a spiral cutting process to form two spiral ports 2 at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com