Improved chemical pump

An improved technology for chemical pumps, applied to pumps, pump components, non-variable pumps, etc., can solve the problems of poor safety and reliability of pump operation, short service life of bearings, and solid particles, so as to improve safety and reliability. The effect of prolonging the service life and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

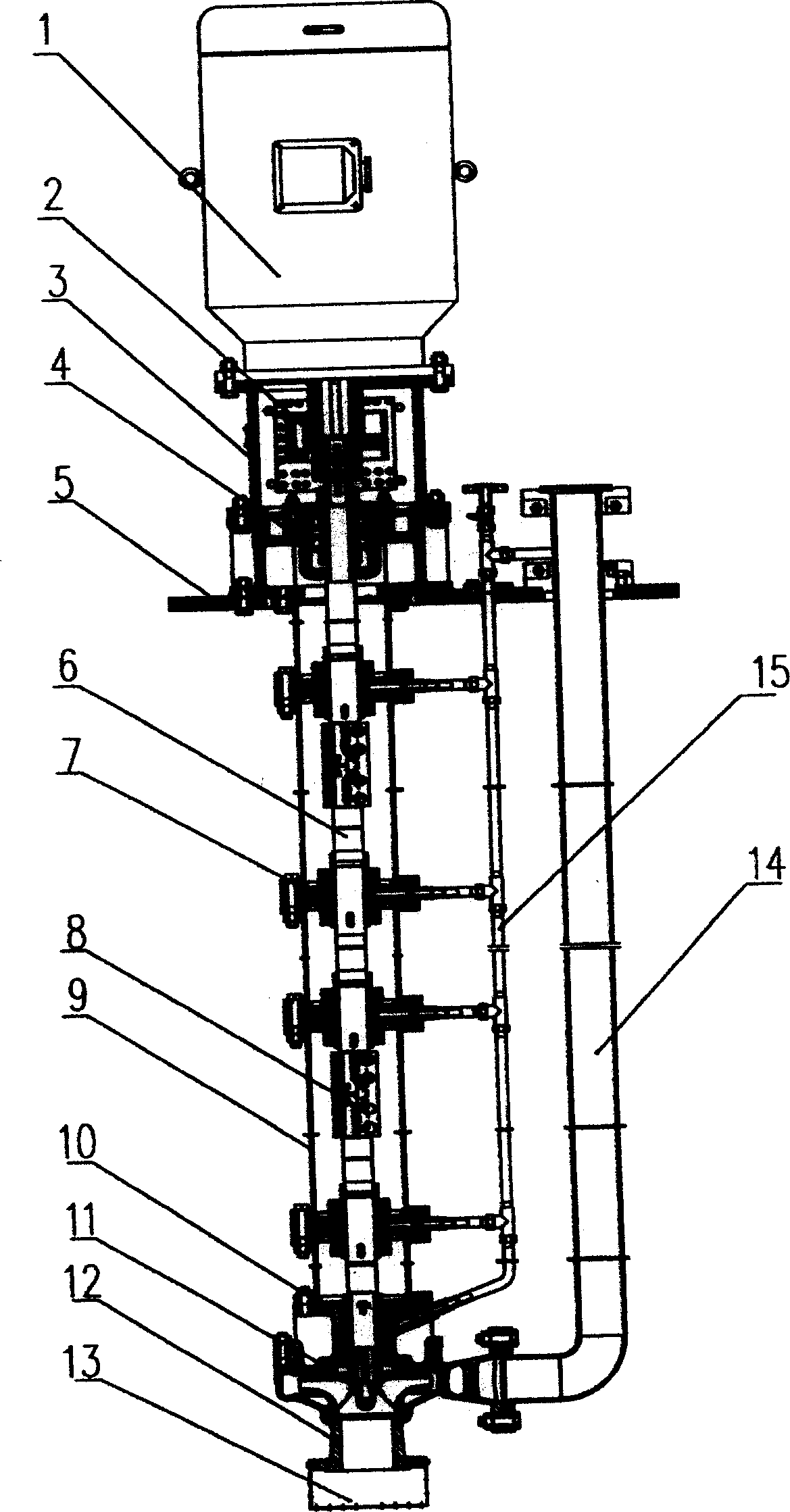

[0009] see figure 1 , figure 2 , The motor 1 is a dry motor, the motor 1 is installed on the motor base 3, the motor base 3 and the bearing part 4 are connected by bolts, and the whole pump set composed of the rotor part and the support part is installed on the installation base 5. The elastic pin coupling 2, the drive shaft 6, the clamp coupling 8 and the impeller 11 form the rotor part; the pump body 12, the pump cover 10, the support pipe 9, the bearing part 4 and the guide bearing part 7 form the support part; the motor The main shaft is connected to the transmission shaft 6 with an elastic pin coupling 2, and the transmission shaft 6 is divided into multiple sections, and the clamp coupling 8 is used to connect them into one body. Bearing part 4 is equipped with bearing body and bearing gland, and bearing is housed in bearing body, and axle sleeve is sleeved in the bearing, and axle sleeve adopts key to be fixedly connected transmission shaft 6. The transmission shaft ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com