FPGA-based linear cutting device control device and method

A technology of equipment control and wire cutting, applied in the direction of program control, computer control, general control system, etc., can solve the problems of inability to realize multi-axis control, poor system stability, simple structure, etc., to improve processing stability, high precision, well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

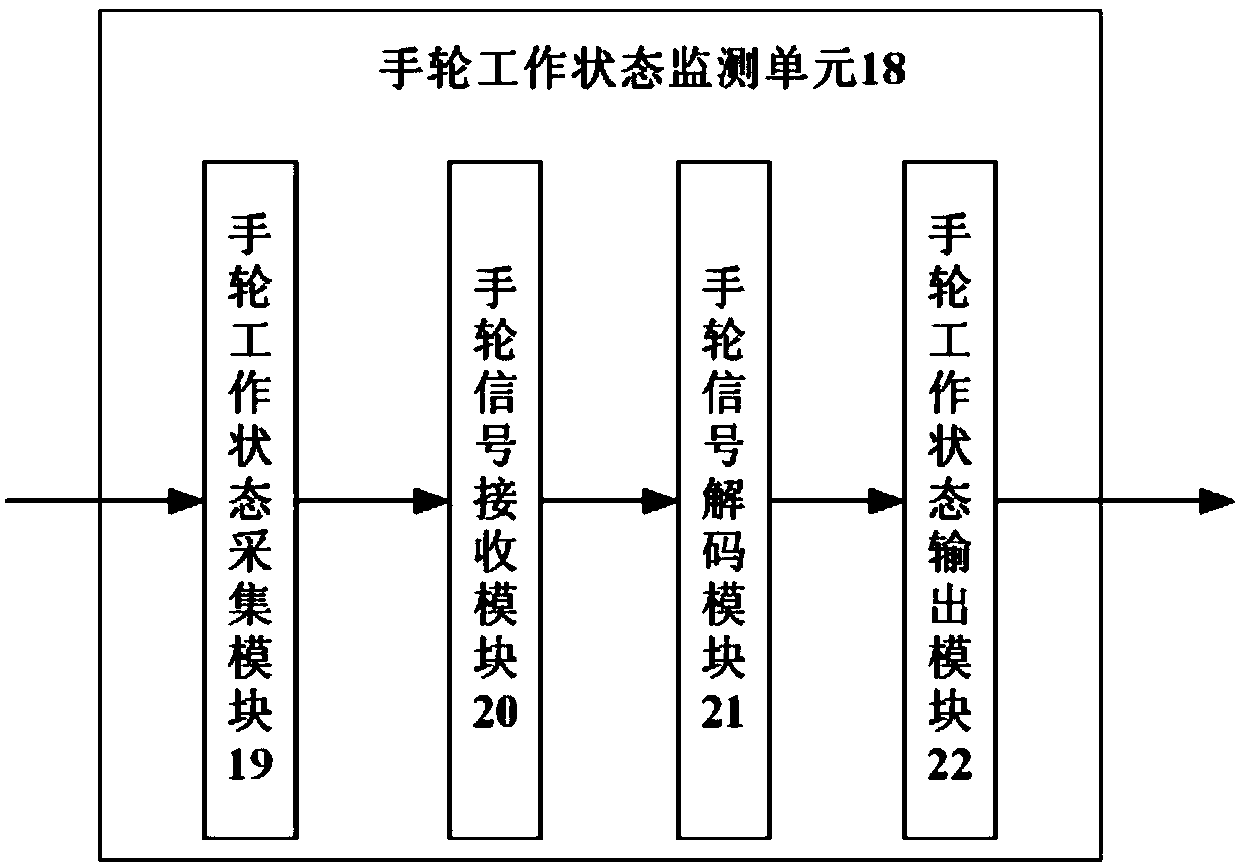

[0030] as attached figure 1 As shown, the present invention proposes a wire cutting equipment control device based on FPGA, which is provided with a host computer 1, a closed-loop control card 2, a motor driver 3, a motor 4, and a lead screw 5, wherein the motor 4 drives the lead screw to move, and the host computer 1 communicates with the closed-loop control card 2, and the closed-loop control card 2 communicates with the motor driver 3, and is characterized in that it is also provided with a grating ruler 6 for collecting the displacement data of the lead screw; the closed-loop control card 2 is provided with a closed-loop control unit 7, closed-loop The front end of the control unit 7 is provided with a signal decoding unit 8 for identifying and decoding the commands of the host computer, and the rear end of the closed-loop control unit 7 is provided with a coding o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com