Food processor easy to clean

A food processing machine, easy-to-clean technology, applied in household utensils, applications, kitchen utensils, etc., can solve the problems of difficult cleaning, large amount of cleaning water, poor crushing effect, etc., and achieve low noise, good cleaning effect, and small operating vibration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

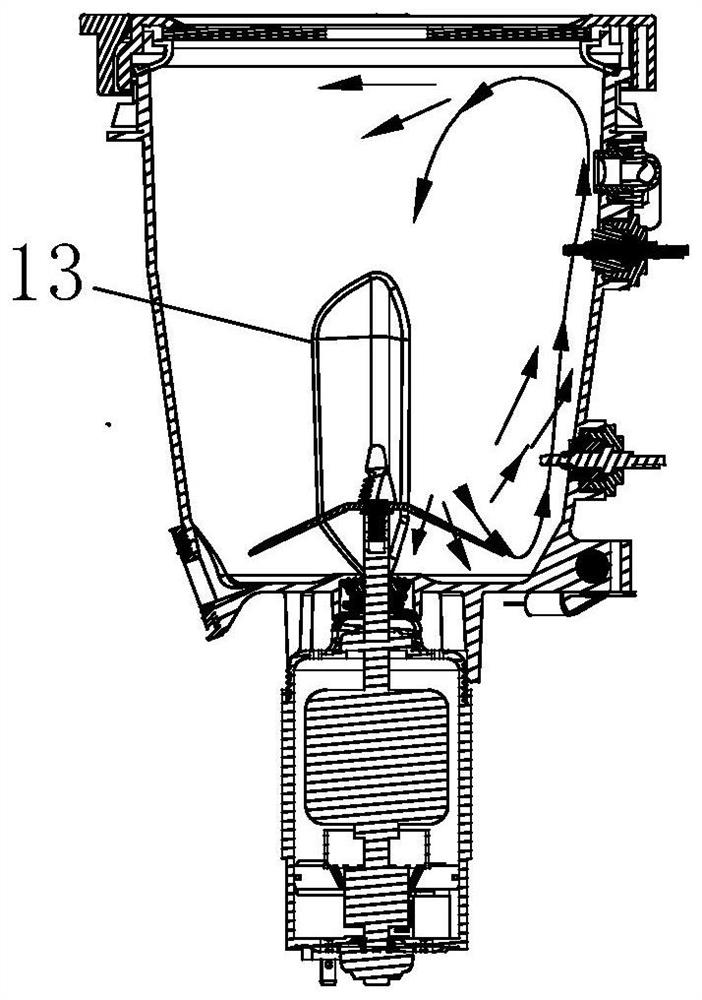

[0029] The invention relates to a food processing machine. Includes cups for food processors such as figure 1 As shown, the bottom of the cup 1 is provided with a motor 2, and the motor shaft of the motor 2 passes through the bottom of the cup 1 and is connected with the crushing cutter 4 arranged inside the cup 1. The cup A cup cover 3 is provided on the body 1, and the cup cover 3 and the cup body 1 encircle to form a food processing area for crushing and processing materials.

[0030] In this embodiment, the cup body 1 includes a cup body side wall 11 and a cup body bottom wall 12 , and the cup body side wall 11 is inclined relative to the center vertical line of the cup body 1 . The inclined design of the side wall 11 of the cup body makes it easier for the cleaning water to climb up the side wall 11 of the cup body during cleaning, which is conducive to cleaning the upper part of the side wall 11 of the cup body and the cleaning of the cup cover 3, and effectively improv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com