Resin sheet, liquid crystal cell substrate, liquid crystal display, substrate for electroluminescent display, electroluminescent display, and substrate for solar cell

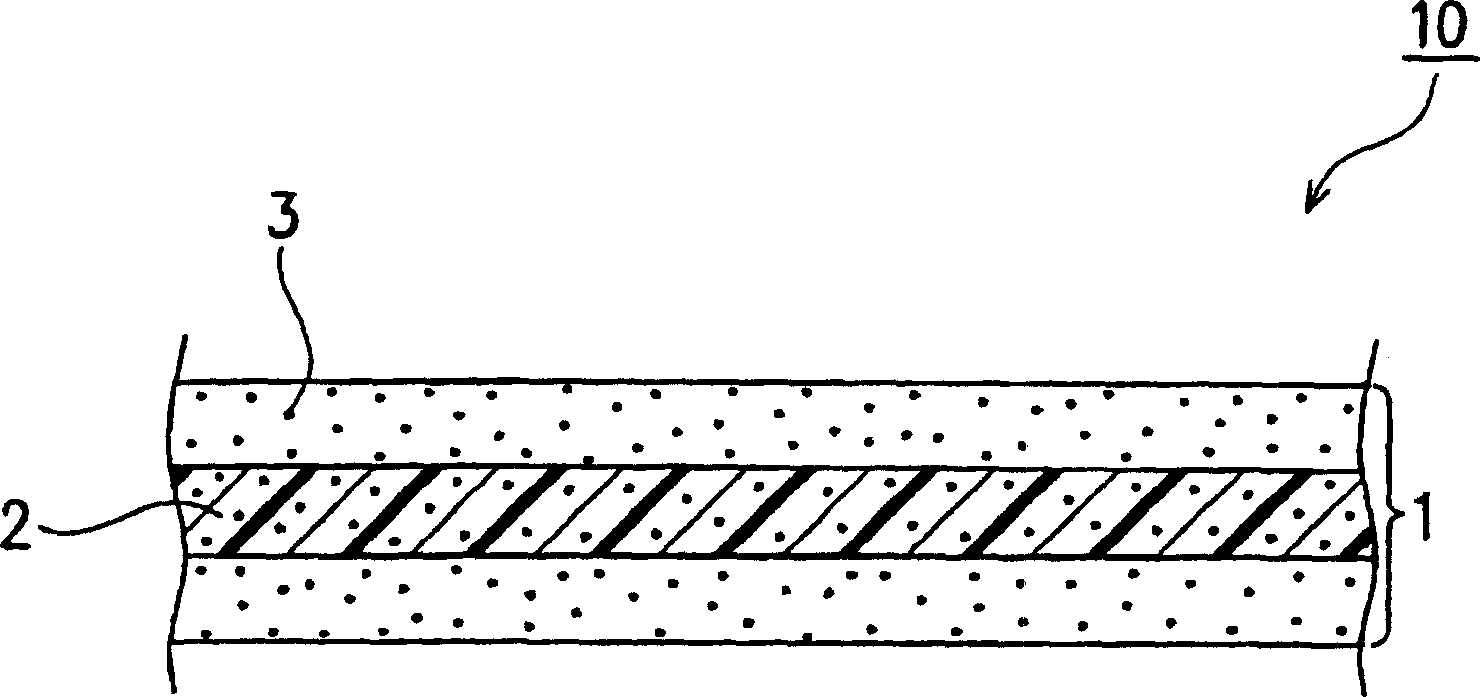

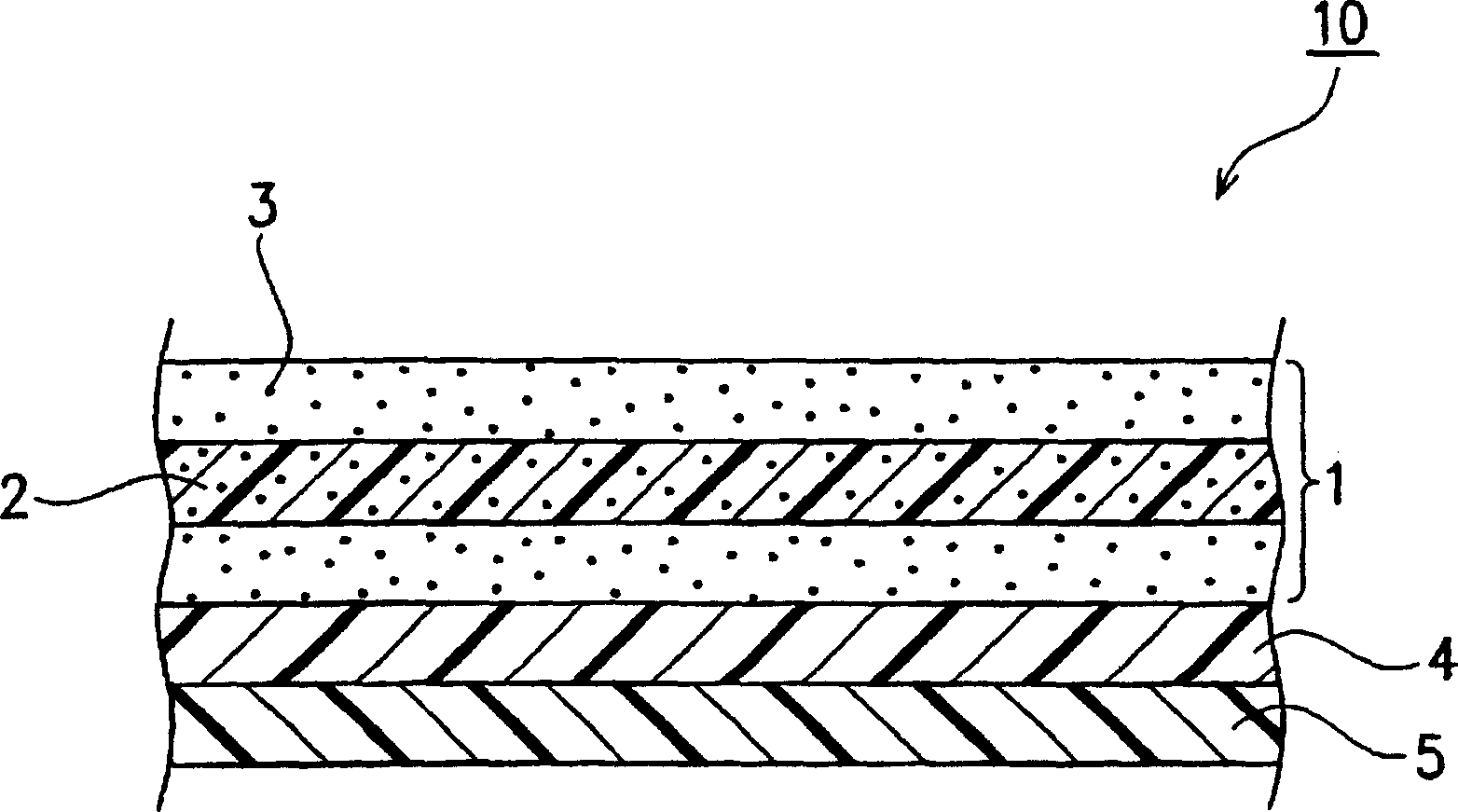

An electroluminescence display and resin sheet technology, applied in the field of resin sheets, can solve problems such as the adverse effect of light transmittance, and achieve the effects of excellent light transmittance, avoiding position shift and improving impact resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

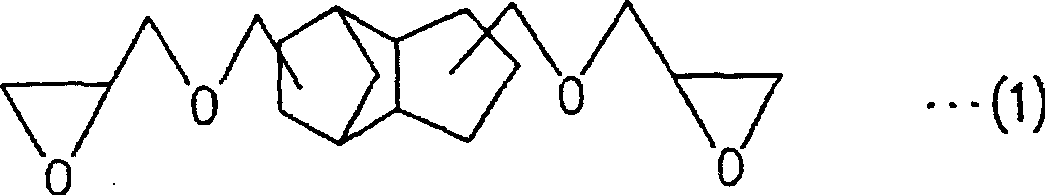

Embodiment 1

[0082] Silica particles (average particle diameter: 15 nm) as inorganic particles are used in such a way that the amount of epoxy resin is 24.6 parts (parts by weight, the same below), which is represented by chemical formula (3) and is uniformly dispersed by sol-gel reaction. 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexanecarboxylate (trade name "NANOPOX XP22 / 0316", manufactured by Hanse Chemie Co.), stirred and mixed with the following chemical formula (4) Dicyclopentadiene type epoxy resin (trade name "EXA-7230" (epoxy equivalent 259), manufactured by Dainippon Ink Chemical Industry Co., Ltd.) 6.9 parts, 36.2 parts of methyl norbornene dianhydride as a curing agent, as 0.72 parts of tetra-n-butylphosphonium o, o-diethylphosphoric acid dithioester represented by the following chemical formula (5) of the curing accelerator, prepared a ring with a content of silica particles in the cured resin layer of 31.5% by weight. Oxygen resin liquid.

[0083] [Chem 3]

[0084]

[008...

Embodiment 2

[0094] A resin sheet was produced in the same manner as in Example 1 except that the content of the silica particles in the cured resin layer was 23% by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com