Multi-mode interference beam splitter and apparatus and method for preparing the same

A multi-mode interference and beam splitter technology, applied in the direction of optical waveguide and light guide, can solve the problems of increased optical transmission loss, difficulty in controlling the preparation process, and large wafer area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

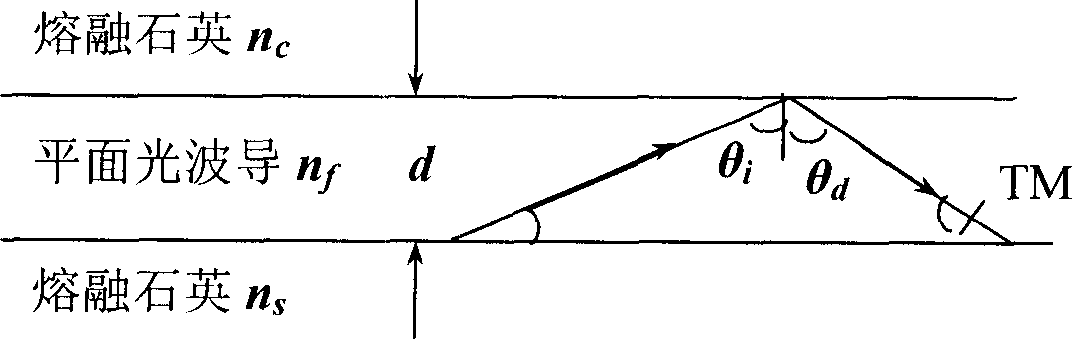

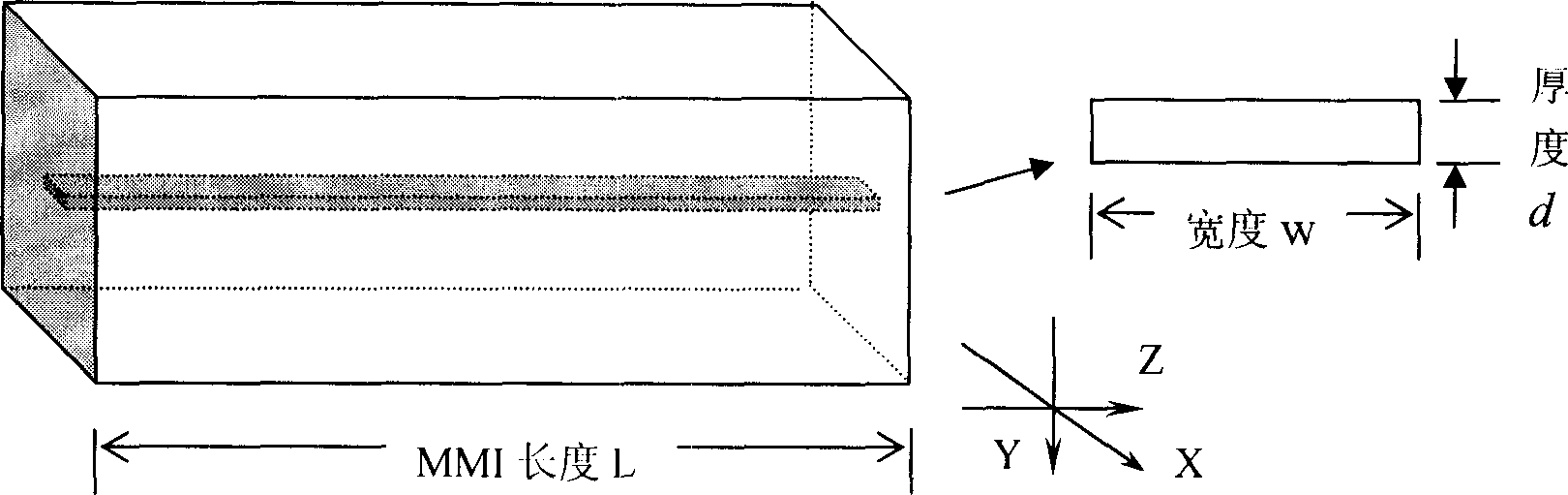

[0074] Embodiment 1: Single MMI waveguide structure beam splitter and its preparation device and method

[0075] Such as Figure 5 Shown is a schematic diagram of a device for preparing a multimode interference beam splitter (MMI), including: ultrashort pulse laser 1, energy and pulse width tuning measurement device 3, shutter 4, beam shaping and filter 5, focusing objective lens 6, Three-dimensional numerical control translation platform 8, CCD detector 9, signal transmission line 10 and computer 11, the connection relationship between each component is as follows Figure 5 As shown, among them, the energy and pulse width tuning measurement device 3, the shutter 4, the three-dimensional numerical control translation stage 8 and the CCD detector 9 are all connected to the computer through the signal transmission line. Among them, the ultrashort pulse laser 1 adopts a titanium sapphire femtosecond laser, and its output laser beam 2 has a wavelength of about 800 nm (nanometer) ...

Embodiment 2

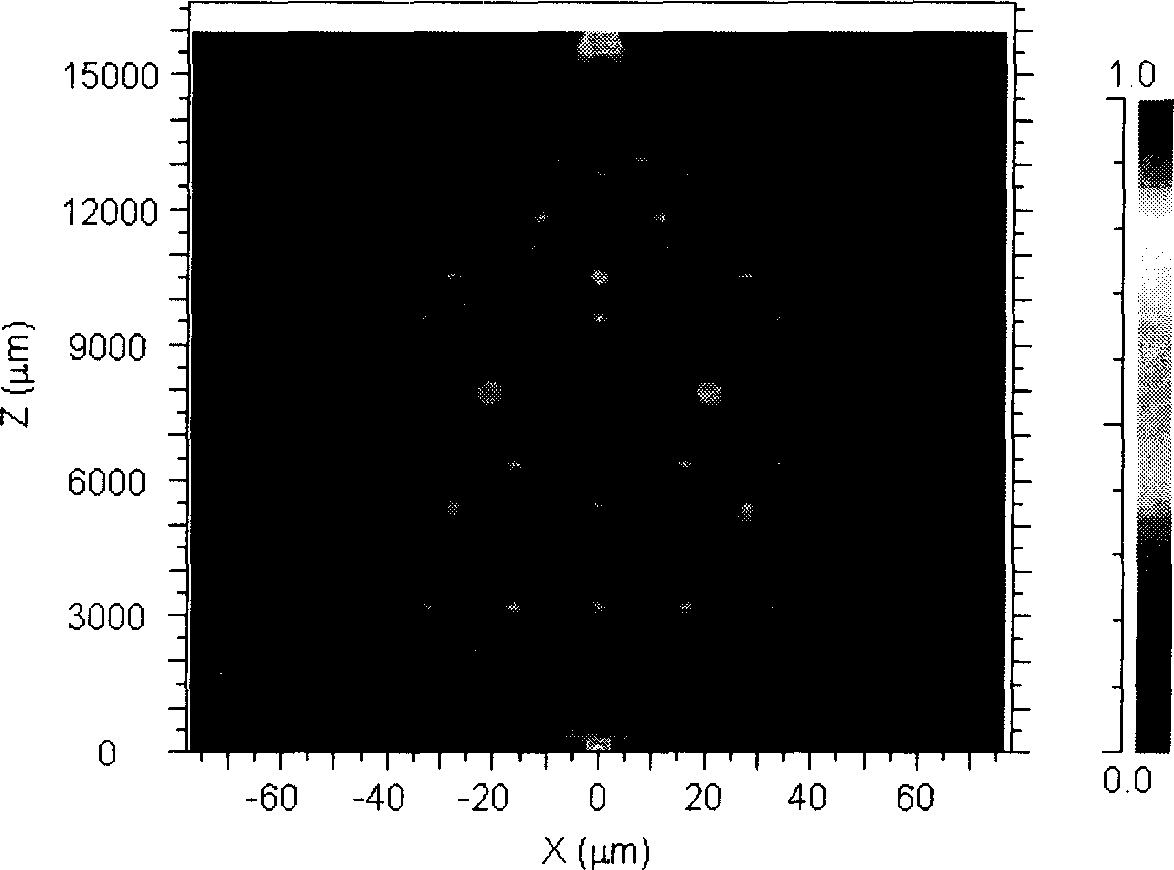

[0079] Example 2: An array beam splitter composed of double MMI beam splitters and its preparation device and method

[0080] The device for preparing the array beam splitter composed of double MMI beam splitters is the same as the device in Embodiment 1, and the steps are basically the same. The specific process is as follows: the laser beam 2 output by the ultrashort pulse laser 1 is subjected to beam shaping and filter 5 filtering The spatial fundamental mode is obtained, after the energy attenuator and the energy meter (not shown in the figure) are adjusted to obtain the appropriate energy, the shutter 4 is used to focus on the sample 7 on the three-dimensional numerically controlled translation stage 8 with the focusing objective lens 6, and the The samples are made of fused silica. The single pulse energy used was about 2.0 μJ, and the filaments produced due to the refractive index change in the sample 7 caused by the laser beam were about 200 μm. When the vertical self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com