Plate-shell type heat exchanger

A heat exchanger, plate-and-shell technology, applied in the field of heat exchange and heat recovery equipment, can solve the problems of the limitation of heating and cooling speed, inconsistent temperature response speed, large thermal expansion difference, etc., to improve the pressure bearing capacity, expand the scope of use, The effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

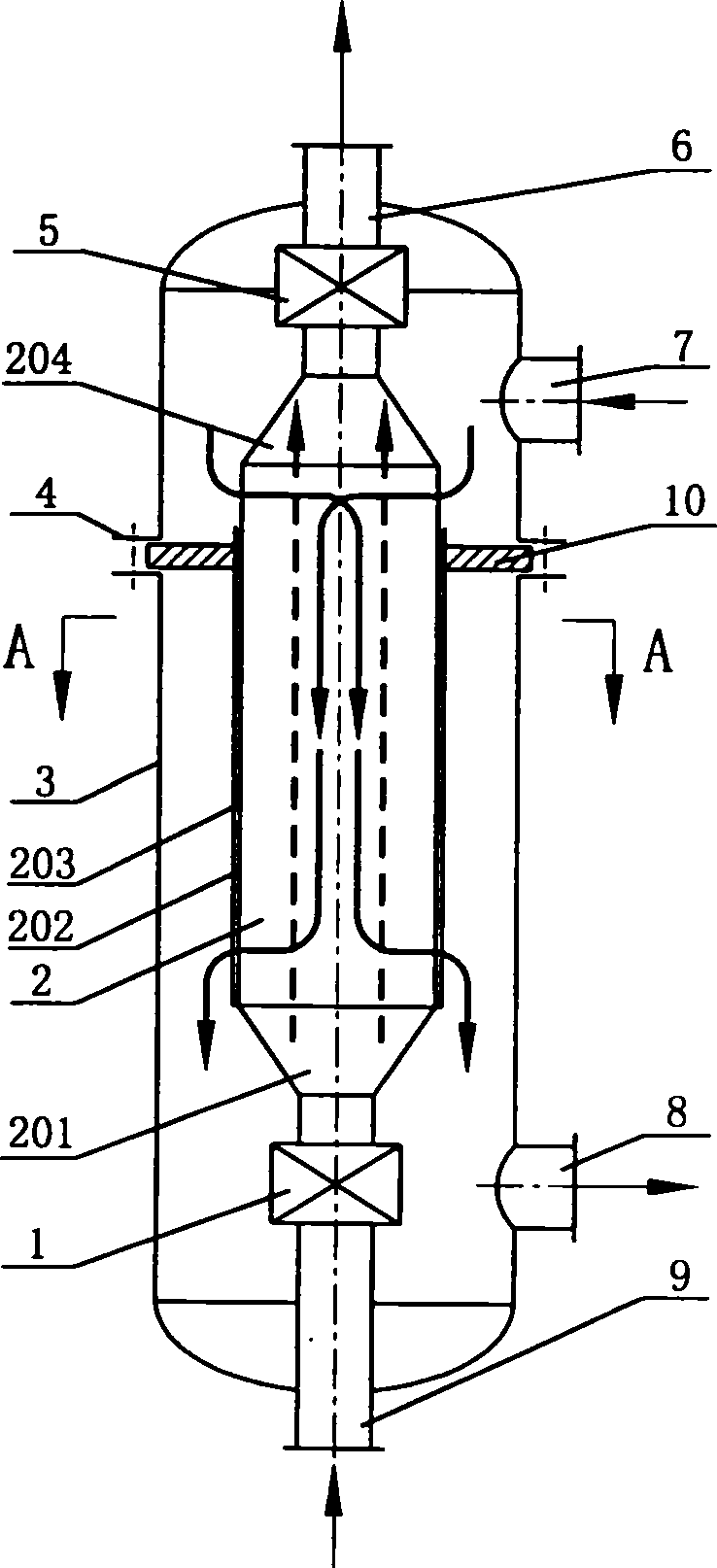

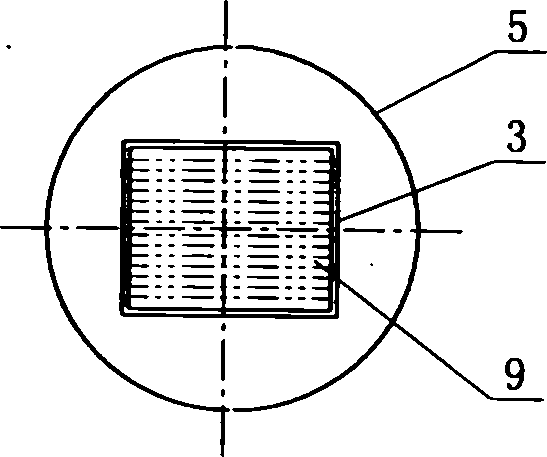

[0023] refer to figure 1 , figure 2 As shown, a plate and shell heat exchanger is mainly composed of a fixed end expansion joint 1, a plate bundle assembly 2, a shell 3, an equipment flange 4, a free end expansion joint 5, a plate side medium outlet connection 6, and a shell side medium Inlet pipe 7, shell-side medium outlet pipe 8, plate-side medium inlet pipe 9, support tube plate 10, etc., using corrugated plates as heat transfer elements; the shell 3 is cylindrical, and there are plate Bundle assembly 2, its connection method can be clamped or welded by the equipment flange 4, the weight of the plate bundle assembly 2 is borne by the shell 3; the lower end of the plate bundle assembly 2 is connected to the fixed end expansion joint 1 through the board-side medium inlet nozzle 9, and the upper end The expansion joint 5 at the free end is connected to the plate-side medium outlet connection pipe 6 to absorb thermal expansion, so as to realize the inflow and outflow of the ...

Embodiment 2

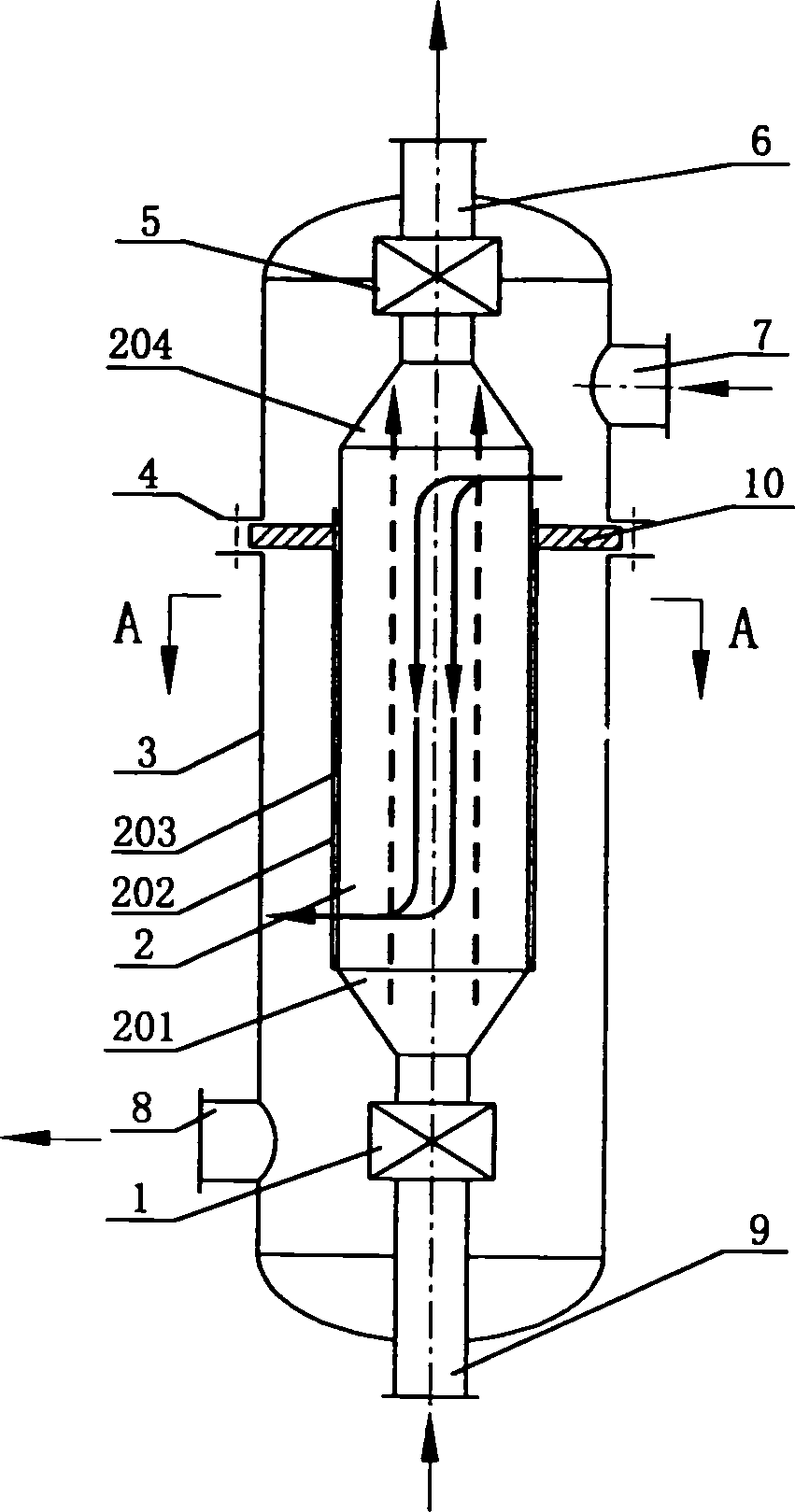

[0028] refer to image 3 As shown, only one side opening 2021 may be provided at the lower end of the board bundle housing 202, and the rest of the structure is the same as that in Embodiment 1.

Embodiment 3

[0030] refer to Figure 4 As shown, the equipment flange 4 may not be provided as required, and the remaining structures are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com