Biodiesel oil multiple-grade molecular distillation process and its device

A two-stage molecular distillation and molecular distillation technology, which is applied in the field of biodiesel multistage molecular distillation process and its devices, can solve the problems of process control uncertainty, long boiling range of biodiesel, and more product entrainment, and achieve simple equipment operation Ease of operation, short material residence time, and improved product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

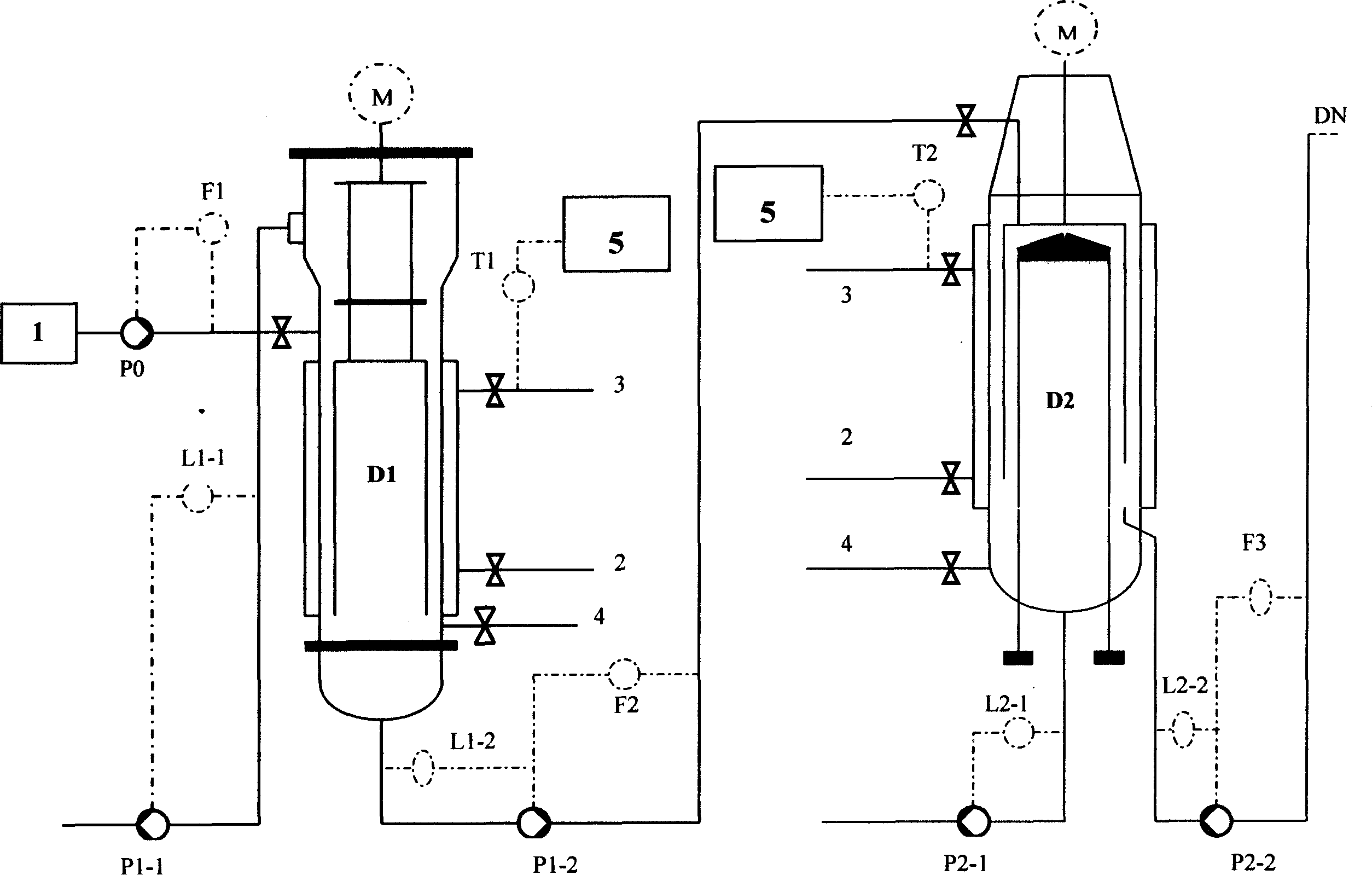

[0019] A biodiesel secondary molecular distillation process, comprising the following processes:

[0020] a. Biodiesel raw material 1 is sent to the primary molecular still D1 through the raw material pump P0 and the feed valve, and the component C12 and below C12 fatty acid methyl ester, water and air are evaporated, and the distillate is passed through the primary discharge pump P1 -1 is sent to the storage tank, and the undistilled material is sent to the feed valve of the secondary molecular still D2 through the primary delivery pump P1-2 and enters the distillation chamber of the still D2; the vacuum degree is controlled to 150Pa, and is passed through the temperature controller T1 controls the temperature in molecular still D1 to be 130°C.

[0021] b. The material entering the secondary molecular still D2, according to the needs of the distillation range, distills the fatty acid methyl esters above component C14 and C14, and sends it into the storage tank through the sec...

Embodiment 2

[0023] A four-stage molecular distillation process for biodiesel, comprising the following processes:

[0024] a. Biodiesel raw material 1 is sent to the primary molecular still D1 through the raw material pump P0 and the feed valve, and the component C10 and below C10 fatty acid methyl ester, water and air are evaporated, and the distillate is passed through the primary discharge pump P1 -1 is sent to the storage tank, and the undistilled material is sent to the feed valve of the secondary molecular still D2 through the primary delivery pump P1-2 and enters the distillation chamber of the still D2; the vacuum degree is controlled to 200Pa, and the temperature is controlled by the temperature controller T1 controls the temperature in the molecular still D1 to be 150°C.

[0025] b. For the materials entering the secondary molecular still, according to the distillation range, the fatty acid methyl esters of components C12-C16 are distilled out, and sent to the storage tank throu...

Embodiment 3

[0029] A biodiesel six-stage molecular distillation process. After four-stage distillation in step d of the above-mentioned embodiment 2, if the remaining materials need to be further rectified, the undistilled materials can be sent into the The fifth-stage and sixth-stage distillers D5 and D6 (the same structure and connection relationship as the second-stage molecular still D2), carry out the fifth-stage and sixth-stage rectification, and completely distill out the components above C24, and in the sixth stage Stage molecular distiller D6, the final distillate is sent to the storage tank through the six-stage discharge pump P6-1, and the material that cannot be distilled is sent to the residue collection tank as residue through the six-stage delivery pump P6-2; this implementation In the example, the vacuum temperature parameters in molecular stills D1 and D2 are the same as in Example 2, the vacuum in D3 and D4 is controlled at 10Pa, and the temperature is controlled at 210°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com