Plastic wood template and associated method of production

A production method and formwork technology, applied in the field of building formwork, can solve problems such as environmental hazards, and achieve the effects of easy disassembly, high economic benefits, and wide use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

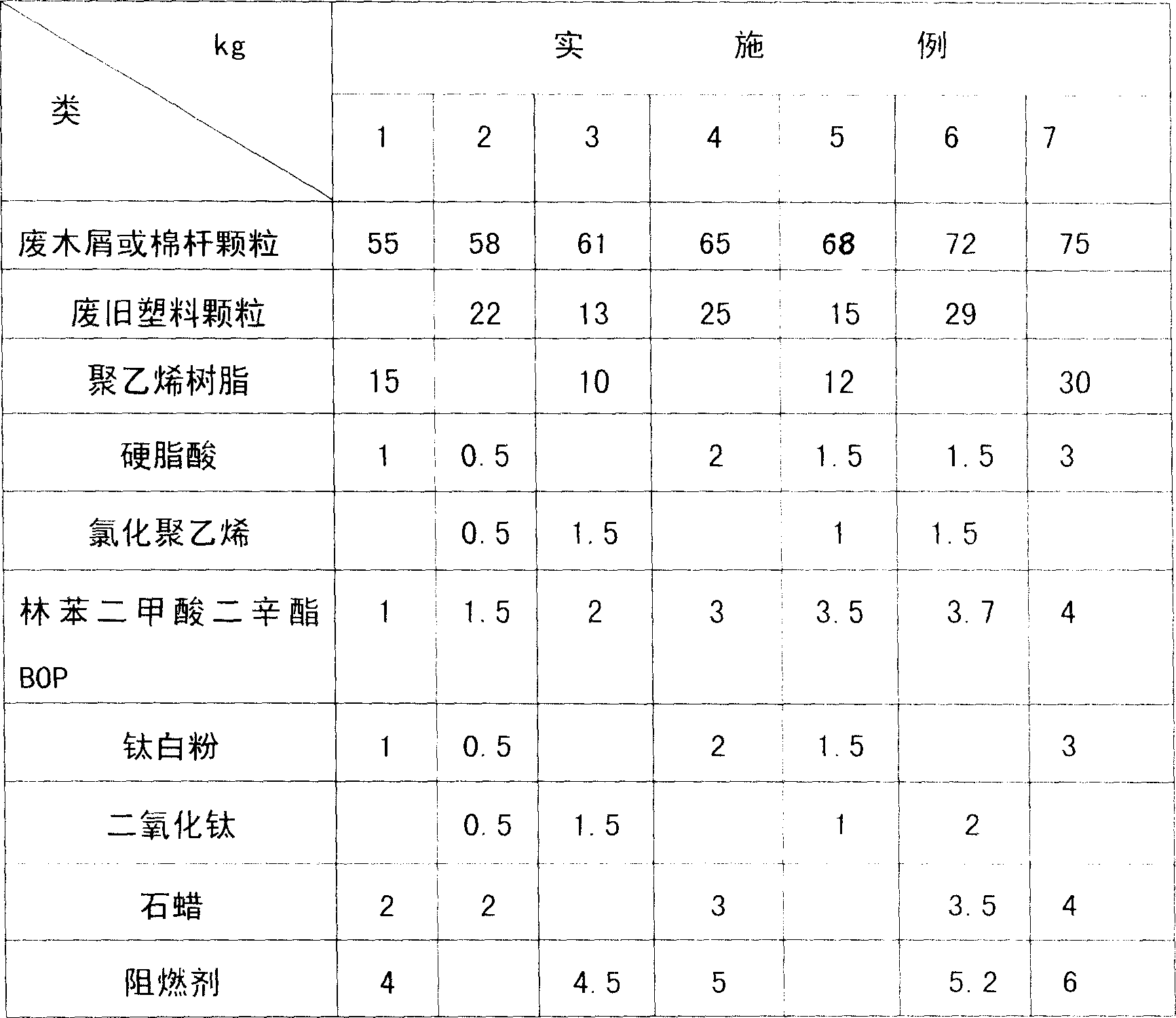

[0014] The ingredients of the components of the embodiment of the present invention are shown in Table 1.

[0015] The process is as follows:

[0016] 1. Raw material preparation and pretreatment: granulate waste wood and cotton stalks and granulate waste plastics such as recycled waste mulch polyethylene;

[0017] 2. Dry with wood flour dryer, hot air dryer, microwave dryer, etc.;

[0018] 3. Mix the ingredients and add modifiers, anti-aging agents, tackifiers, lubricants, flame retardants and other additives at the same time;

[0019] 4. Molding: pressurized and stretched into the initial shape, the temperature is 80-120°C during molding, and the pressure is 0.6-1.2Mpa for at least 10 minutes;

[0020] 5. Cooling;

[0021] 6. Cutting and making finished templates: length x width x thickness = 1500mm x 900mm x 10-15mm.

[0022] Performance test results: all meet the requirements of the acceptance indicators shown in Table 2. The static bending strength shall be carried o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com