Method for removing calcium ion in zinc sulphate solution

A technology for zinc sulfate solution and calcium ions, which is applied to remove calcium sulfate impurities in aqueous solution. The device of the above method can remove calcium ions in zinc sulfate solution and calcium sulfate impurity removal field, so as to shorten the crystallization time and prolong the maintenance cycle , The effect of reducing the consumption of seed crystals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

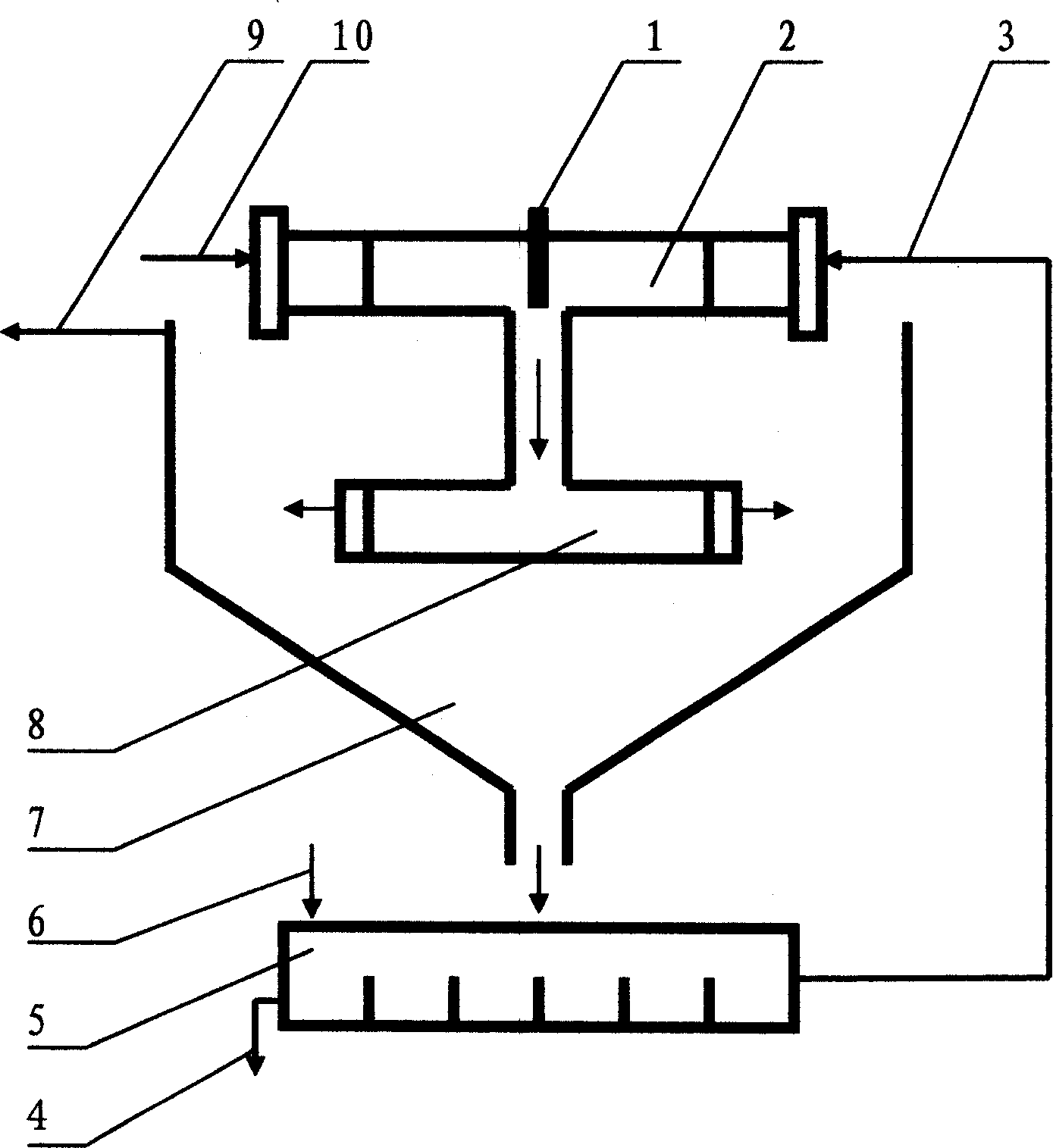

[0027] as attached figure 1 The ultrasonic decalcification tank shown includes an ultrasonic crystal generator (1), a crystal grower (2), a hydraulic agitator (8), a crystallization tank (5), and a thickening tank (7). It is characterized in that: an ultrasonic crystallizer (1) is used to change calcium sulfate from an ion state to a crystalline state, and a crystal grower (2) is used to vigorously mix the liquid to be decalcified (10) with the dense underflow (3) to promote calcium sulfate The crystal (4) is coarse, and the solid-liquid separation is strengthened by using a hydraulic agitator (8), and the crystallization tank (5) is used to realize open-circuit decalcification and dense underflow closed-circuit circulation. in:

[0028] The ultrasonic frequency of the ultrasonic crystal generator is 15-120KHz.

[0029] The ultrasonic crystal generator can be arranged in the crystal grower or at the front end of the liquid inlet.

[0030] The crystal grower is provided with...

Embodiment 2

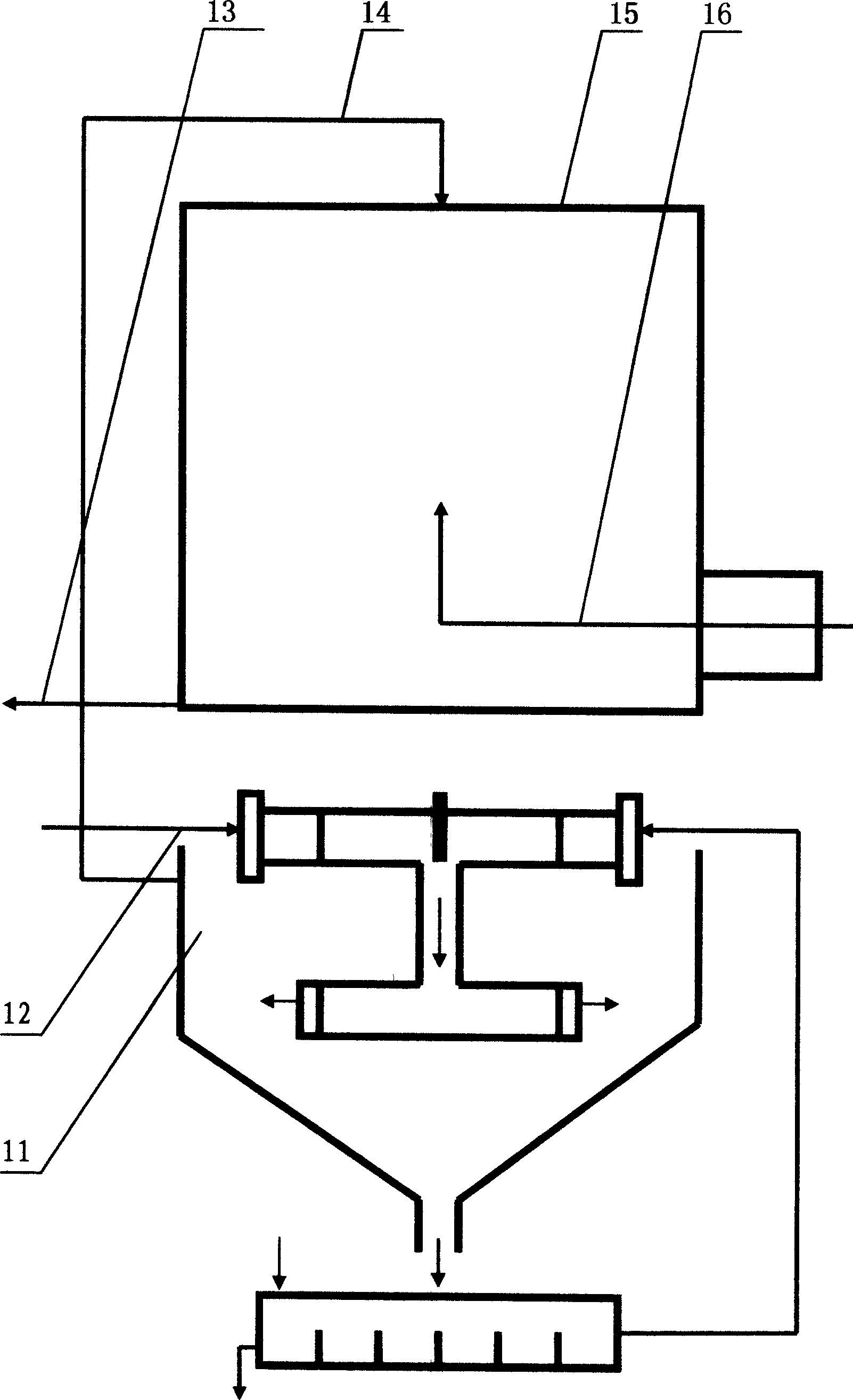

[0037] The ultrasonic decalcification tank is applied to the zinc sulfate solution preparation system for decalcification.

[0038] In the zinc hydrometallurgy process, the zinc sulfate solution preparation system usually includes leaching and purification processes. According to the characteristics of the zinc ore and the requirements of the producer, there are several process systems for the preparation of zinc sulfate solution: high temperature, medium temperature and normal temperature. Among China's wet zinc smelting plants, enterprises with a production scale of more than 100,000 tons of electric zinc per year usually set up an air cooling tower or a thickener to remove calcium in the zinc sulfate solution preparation system. This is due to the needs of the leaching or purification process on the one hand, and on the other hand because the newly prepared zinc sulfate solution is not diluted, and the concentration of calcium sulfate is relatively high. Calcium removal in t...

Embodiment 3

[0042] Apply ultrasonic decalcification tank to decalcification in zinc electrowinning process.

[0043] The zinc electrowinning process is the final process of the wet zinc smelting process, where the zinc sulfate solution passes through the electrolytic cell to deposit elemental zinc. The zinc sulfate solution that enters the electrolytic cell is commonly known as the new electrolytic zinc solution; the zinc sulfate solution after the elemental zinc is precipitated, the concentration of zinc ions decreases and the liquid temperature rises, is commonly referred to as the electrolytic zinc waste solution. The zinc electrowinning process requires that the concentration of zinc ions in the new solution of electrowinning zinc and the liquid temperature of the new solution of electrowinning zinc remain constant. Therefore, it is necessary to continuously replenish zinc sulfate solution with a higher concentration of zinc, and the waste solution of electrowinning zinc must be treate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com