A method for high-strength ultrasonic coupling emulsifier to promote oil crystallization

An emulsifier and oil technology, applied in the direction of oil/fat refining, fat production, etc., can solve the problems of affecting product functionality, slow crystallization of margarine, easy formation of large spherulites, etc. Small, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

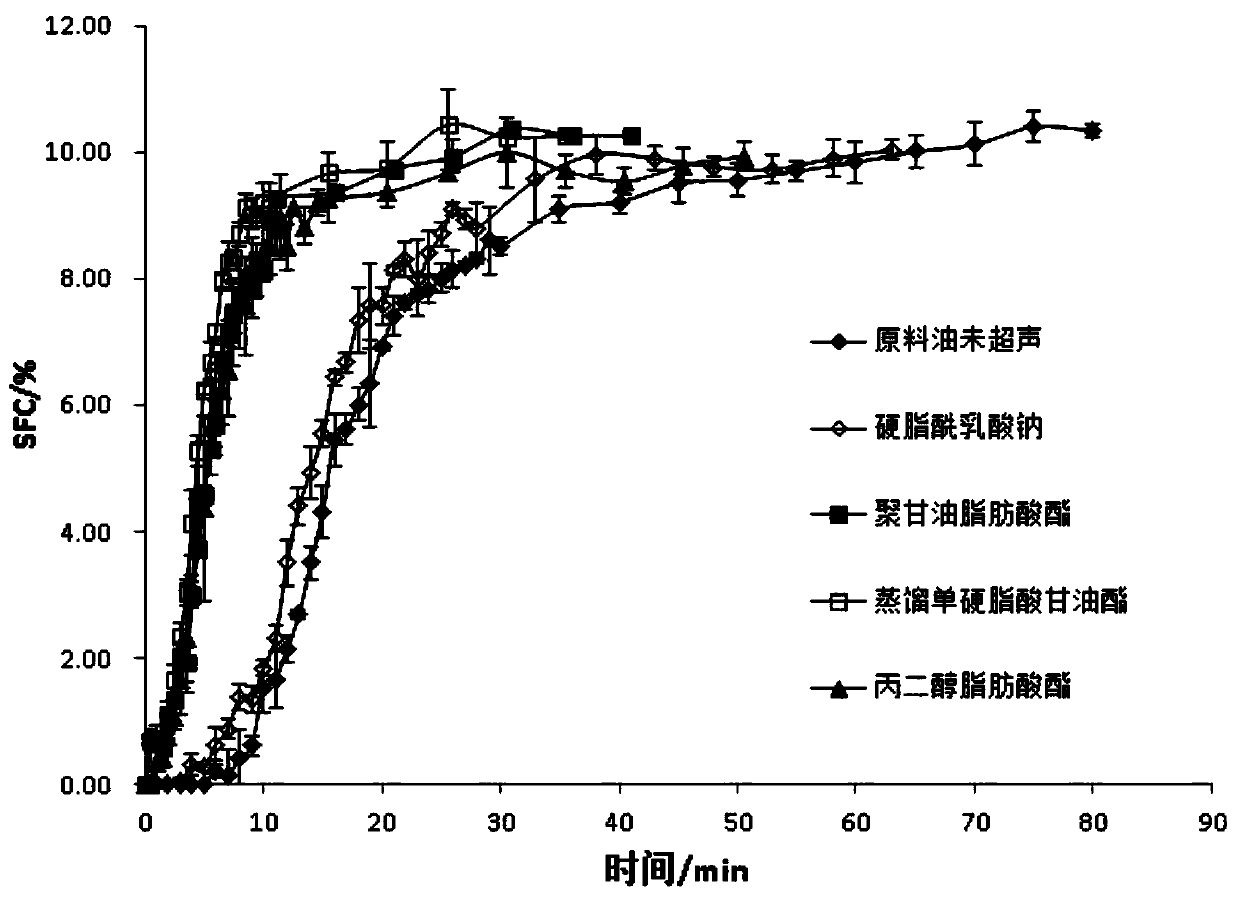

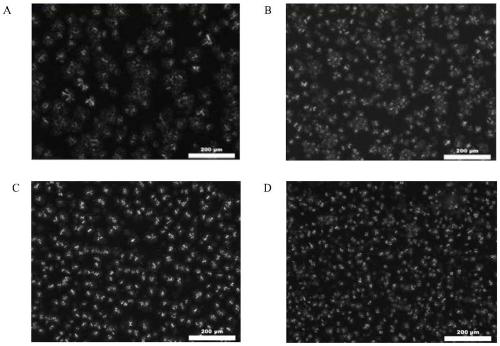

[0025] Take 30g of palm oil in a clean dry container and place it in a water bath at 80°C for 30 minutes to eliminate crystallization memory. 0.3 g of distilled glycerol monostearate was added, and the sample was stirred at a rate of 200 rpm for 20 min at 80° C. using a temperature-controlled magnetic stirrer. Weigh 10 g of the sample into a 50 mL centrifuge tube, and cool the sample to 30°C in an ice-water bath. Use high-intensity ultrasound to process the sample, the ultrasonic power is 237.5W, and the ultrasonic time is 30s (including pulse stop, 5s on, 5s off). Pipette 3-4mL samples into special glass tubes for nuclear magnetic resonance, and use a desktop nuclear magnetic resonance instrument to measure the solid fat content every 30s. After the cover glass and slide glass were preheated in a 30°C incubator for 30 minutes, the samples were prepared respectively, and then placed in a 4°C incubator at a constant temperature for 12 hours to observe the crystal microstructur...

Embodiment 2

[0027] Take 30g of palm oil in a clean dry container and place it in a water bath at 80°C for 30 minutes to eliminate crystallization memory. 0.3 g of polyglycerol fatty acid ester was added, and the sample was stirred at a rate of 200 rpm for 20 min at 80° C. using a temperature-controlled magnetic stirrer. Weigh 10 g of sample into a 50 mL centrifuge tube and cool to 30 °C in an ice-water bath. Use high-intensity ultrasound to process the sample, the ultrasonic power is 237.5W, and the ultrasonic time is 30s (including pulse stop, 5s on, 5s off). Pipette 3-4mL samples into special glass tubes for nuclear magnetic resonance, and use a desktop nuclear magnetic resonance instrument to measure the solid fat content every 30s. After the cover glass and slide glass were preheated in a 30°C incubator for 30 minutes, the samples were prepared respectively, and then placed in a 4°C incubator for 12 hours at a constant temperature to observe the crystal microstructure under the micro...

Embodiment 3

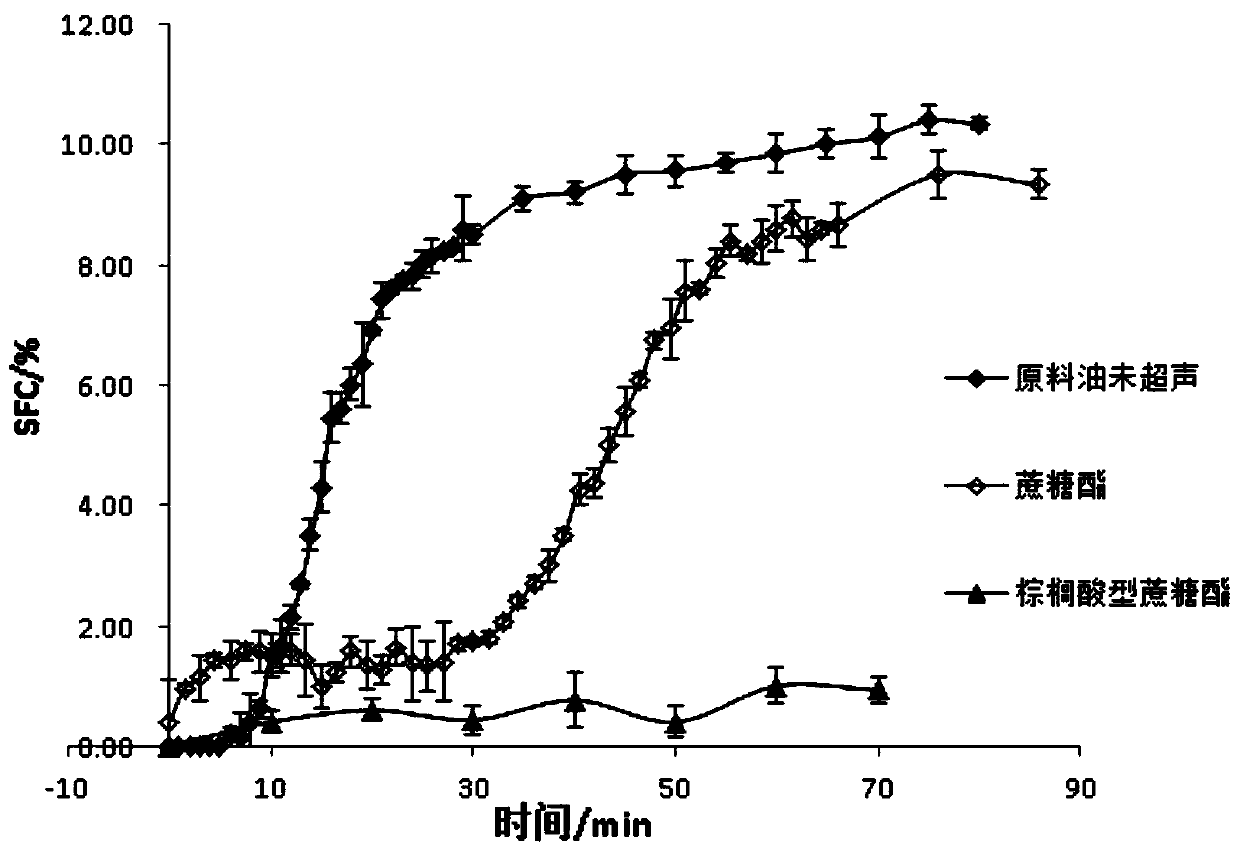

[0029] Take 30g of palm oil-based compound fat (24°C palm olein: 54°C palm stearin: soybean oil = 45:35:20, w / w / w) and put it in a clean and dry container, put it in a water bath at 80°C 30min, eliminate crystal memory. Add 0.3 g of propylene glycol fatty acid ester, and use a temperature-controlled magnetic stirrer to stir the sample at a rate of 200 rpm for 20 min at 80° C. Weigh 10 g of sample into a 50 mL centrifuge tube and cool to 30 °C in an ice-water bath. Use high-intensity ultrasound to process the sample, the ultrasonic power is 237.5W, and the ultrasonic time is 30s (including pulse stop, 5s on, 5s off). Pipette 3-4mL samples into special glass tubes for nuclear magnetic resonance, and use a desktop nuclear magnetic resonance instrument to measure the solid fat content every 30s. After the cover glass and slide glass were preheated in a 30°C incubator for 30 minutes, the samples were prepared respectively, and then placed in a 4°C incubator for 12 hours at a cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com