Electro-optical display device and method for manufacturing same

An electro-optical display and manufacturing method technology, applied in semiconductor/solid-state device manufacturing, circuits, electrical components, etc., can solve problems such as deviation, narrow selection of source/drain electrode materials, and difficulty in controlling the thickness of a-Si film. Effects of current suppression, simplification of manufacturing process, and prevention of deterioration of off-state characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076]

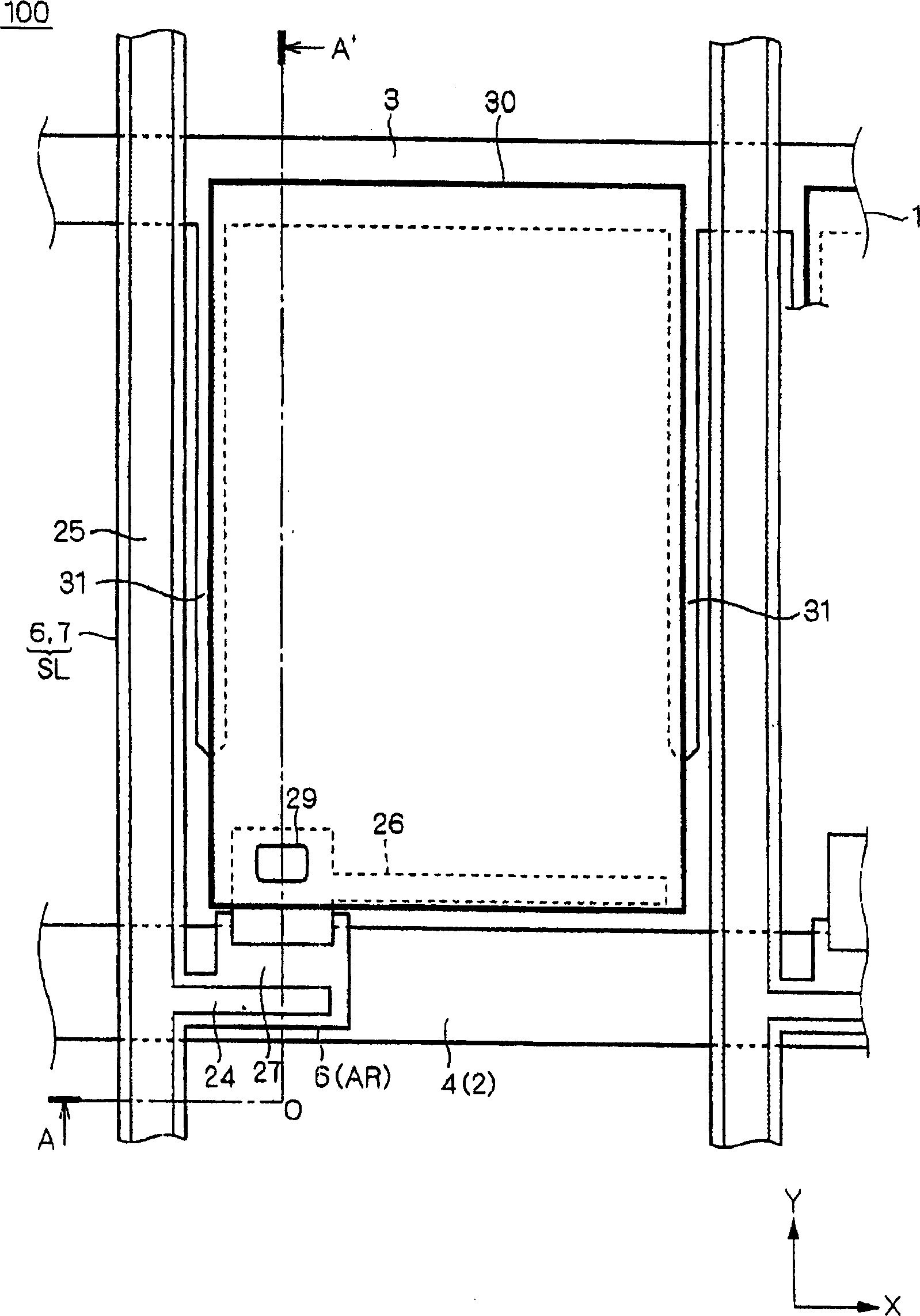

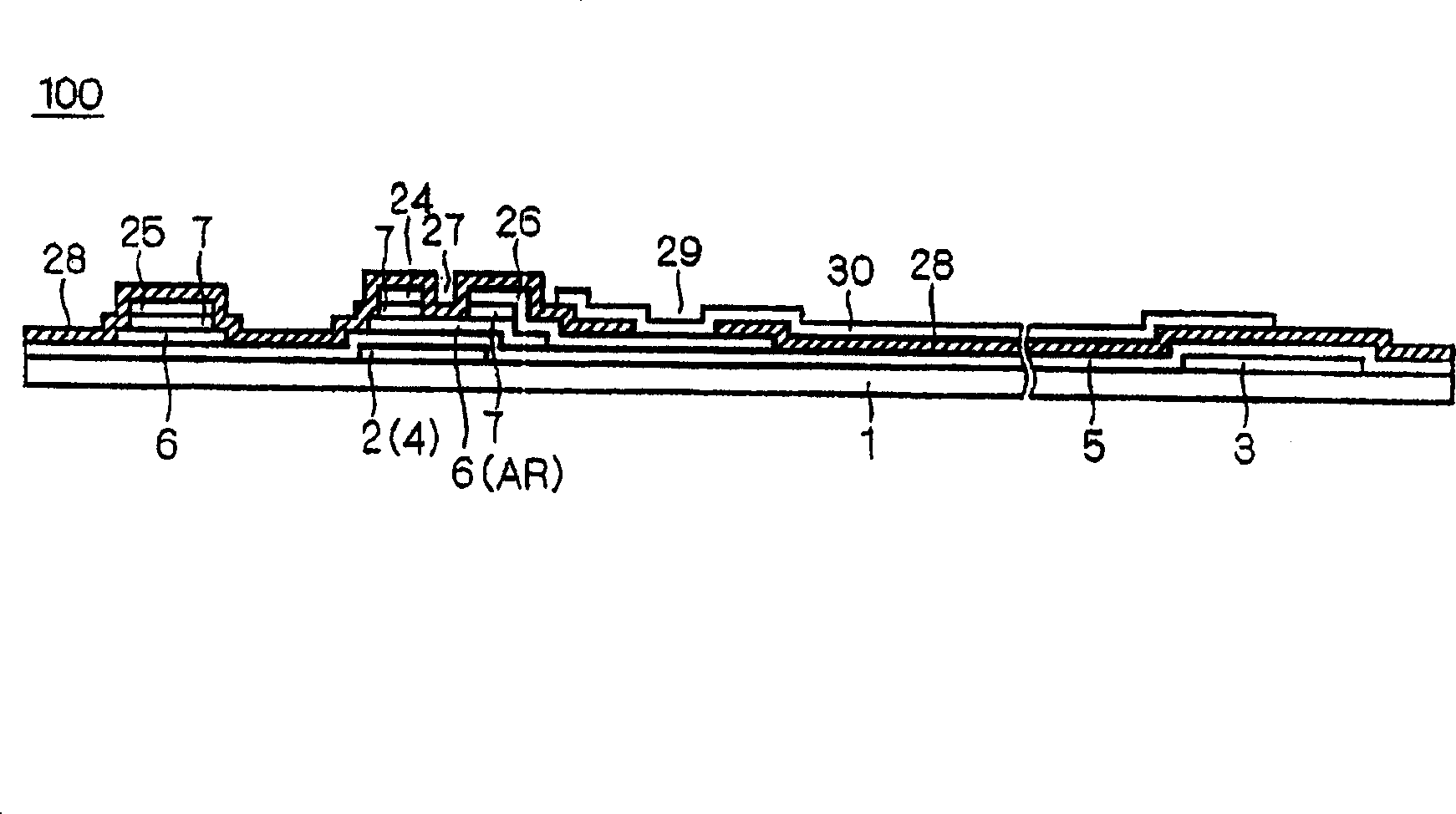

[0077] As the electro-optical display device of Embodiment 1 of the present invention, in figure 1 A planar structure of a TFT active matrix substrate 100 of a transmissive liquid crystal display device using TFTs as switching elements is shown, and, in figure 2 show figure 1 The cross-sectional structure on the line A-O-A' in the center.

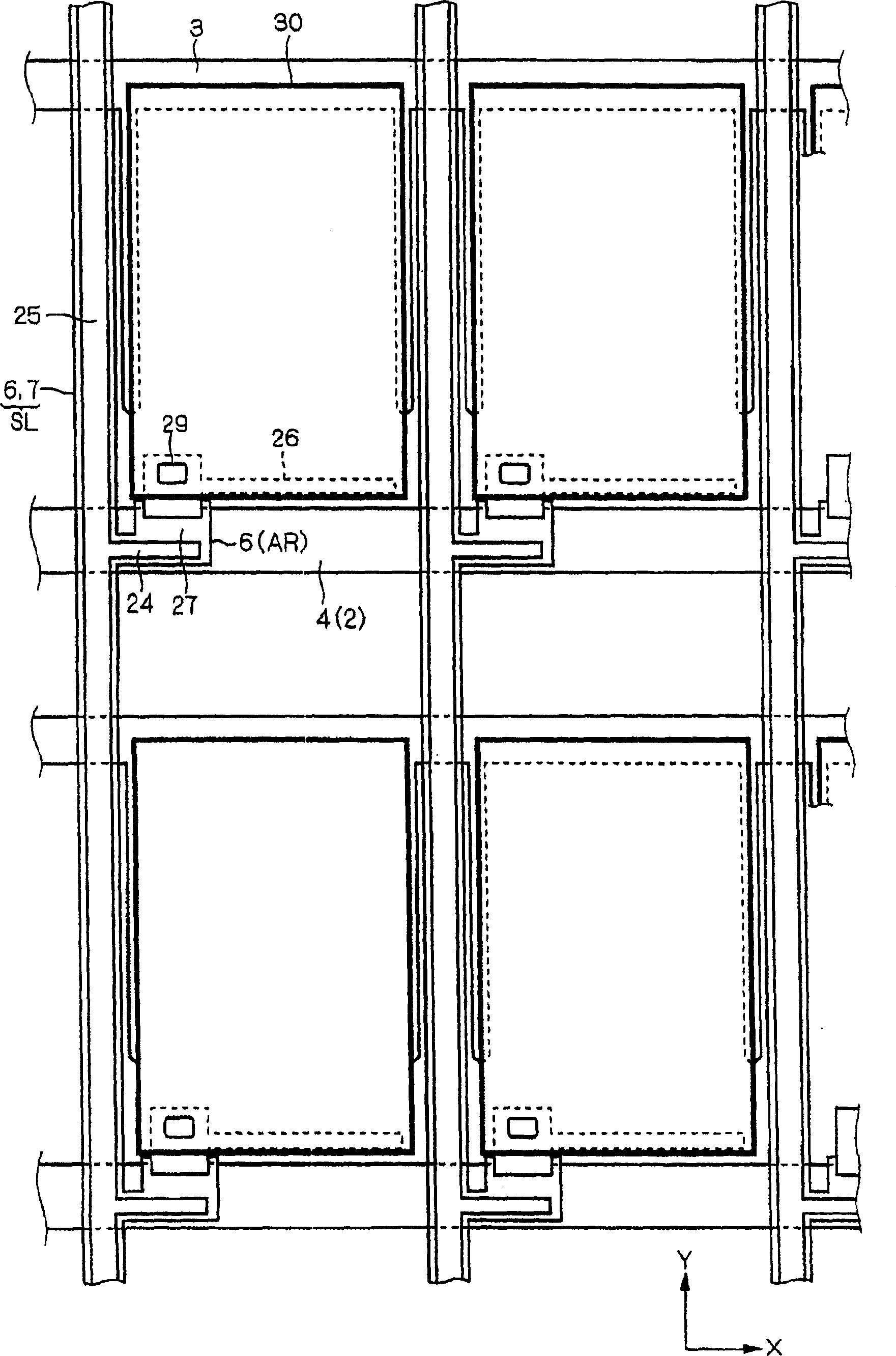

[0078] figure 1 It is a plan view showing one pixel on the TFT active matrix substrate 100, and a plurality of such pixels are arranged in a matrix on the TFT active matrix substrate 100.

[0079] Such as figure 1 As shown, on a transparent insulating substrate 1 such as a glass substrate, a gate wiring 4 partly constituting a gate electrode 2 is arranged. The gate wiring 4 is arranged so as to extend linearly in one direction on the transparent insulating substrate 1 , this direction is referred to as the X direction here, and the direction perpendicular to the X direction in a plane is referred to as the Y direction.

[0...

Embodiment 2

[0161]

[0162] As the electro-optical display device of Embodiment 2 of the present invention, in Figure 23 A planar structure of a TFT active matrix substrate 200 of a self-luminous organic EL display device equipped with an organic electroluminescent (EL) element using a TFT as a switching element is shown, and is shown in FIG. 24 Figure 23 The cross-sectional structure of the B-O-B' line in the middle.

[0163] Figure 23 It is a plan view showing one pixel on the TFT active matrix substrate 200, and a plurality of such pixels are arranged in a matrix on the TFT active matrix substrate 200. Also, in Figure 23 and Figure 24, for the figure 1 and figure 2 The same structure of the shown TFT active matrix substrate 100 uses the same symbols, and repeated descriptions are omitted.

[0164] Such as Figure 23 As shown, on a transparent insulating substrate 1 such as a glass substrate, a gate wiring 4 partly constituting a gate electrode 2 is arranged. The gate wiri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com