Welding Assistance Member And Spot-Welding Method Using Welding Assistance Member

An auxiliary part and spot welding technology, which is applied in the direction of welding/welding/cutting items, welding equipment, resistance welding equipment, etc., can solve the problem of welding quality reduction and achieve the effect of preventing temperature rise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

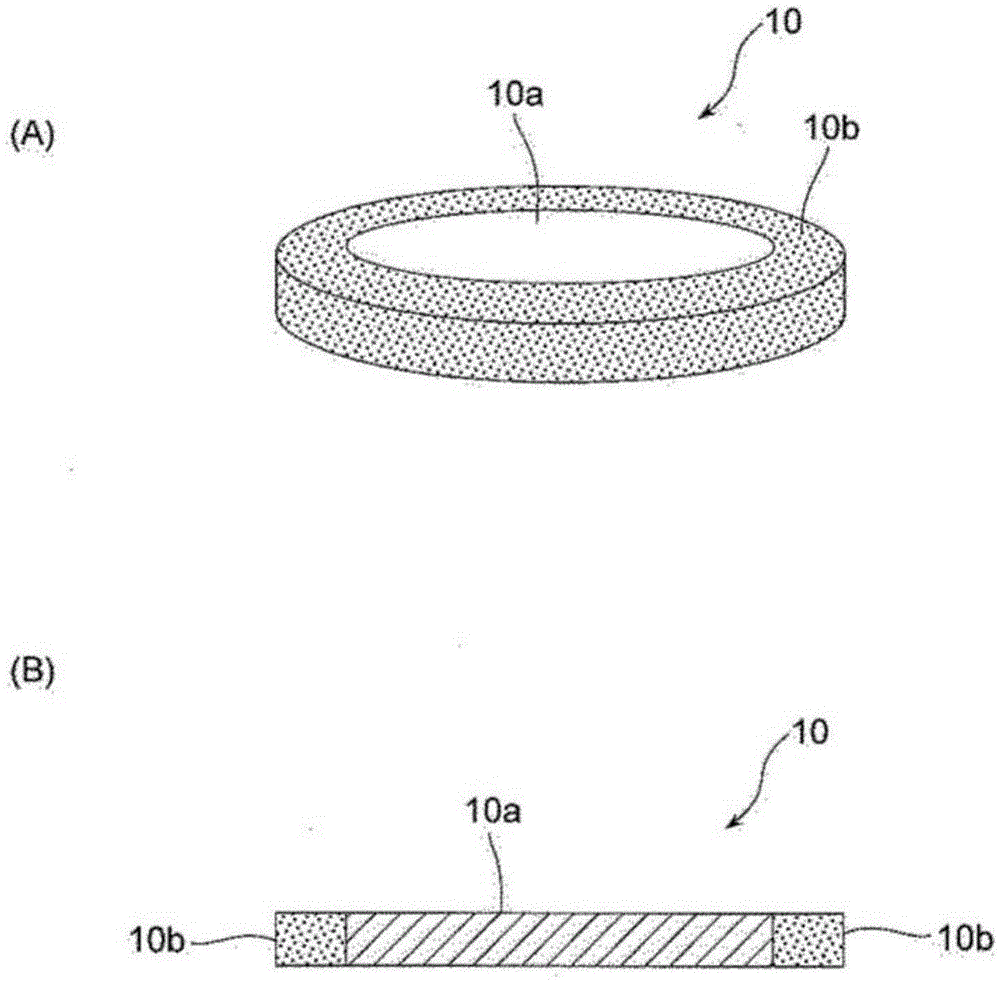

[0039] Next, for the embodiments of the welding auxiliary parts according to the present invention, while referring to the attached Figure 1 Explain in detail.

[0040] figure 1 The structure of the welding auxiliary part 10 according to the embodiment of the present invention is shown, the figure (A) is a perspective view seen from above, and the figure (B) is a cross-sectional view in the thickness direction. In the present embodiment, the welding auxiliary member 10 is composed of a substantially disk-shaped main body 10a and a foam material 10b attached to the outer surface of the main body 10a as a position holding part. The main body portion 10a is made of a conductive material, for example, a metal material mainly composed of iron or the like. In this embodiment, the first materials 12-1 and 12-2 are made of the same material. In this embodiment, the outer diameter of the main body part 10a is shown as about 10 mm. In addition, the thickness of the main body portio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com