Conductive nozzle seat and weld gun

A contact tip seat, contact tip technology, applied in electrode accessories, electrode features, electrode support devices, etc., can solve the problems of increasing the overall cost of the welding torch, increasing the cost of material management, and unavoidable splashes, etc., to save management costs and save Manufacturing cost, effect of preventing electrical conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The application will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain related inventions, rather than to limit the invention. It should also be noted that, for the convenience of description, only the parts related to the related invention are shown in the drawings.

[0024] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present application will be described in detail below with reference to the accompanying drawings and embodiments.

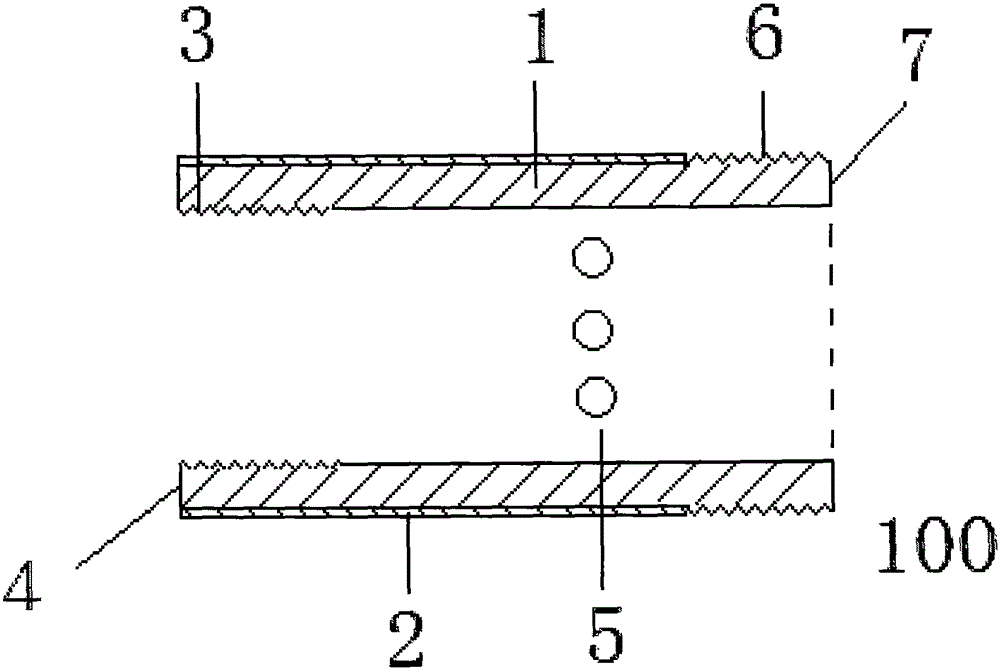

[0025] In the contact tip holder provided in this embodiment, a layer of ceramic material is applied on the outer wall and / or inner wall of the contact tip holder 100 .

[0026] Such as figure 1 As shown, the contact tip holder includes a contact tip holder body 1, a contac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com