Diameter-variable driving wheel and full-automatic micro-shift transmission

A transmission wheel and transmission technology, applied in transmission devices, belts/chains/gears, portable lifting devices, etc., can solve problems affecting the popularization and application of CVT, transmission belt strength, life-limiting transmission belt and pulley friction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

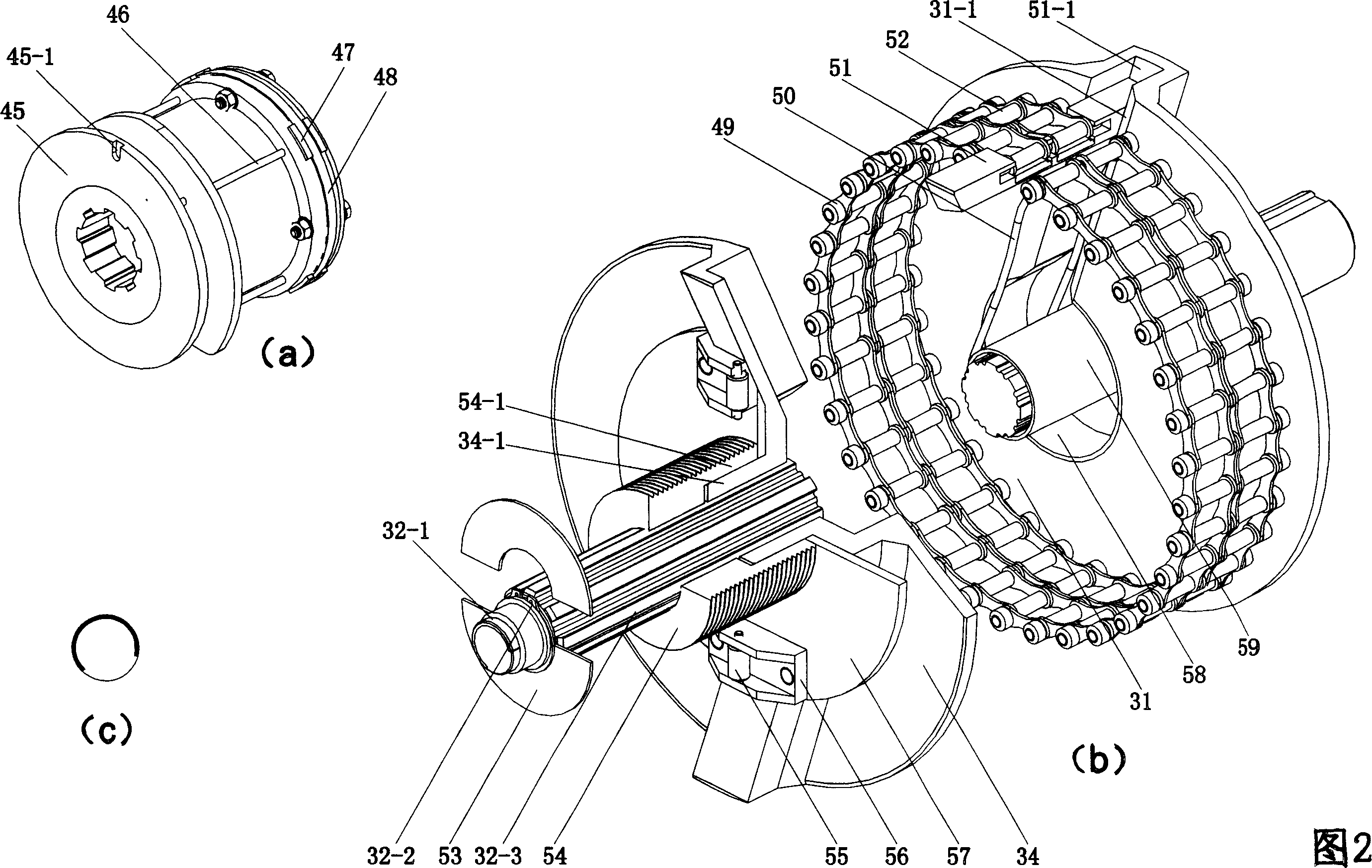

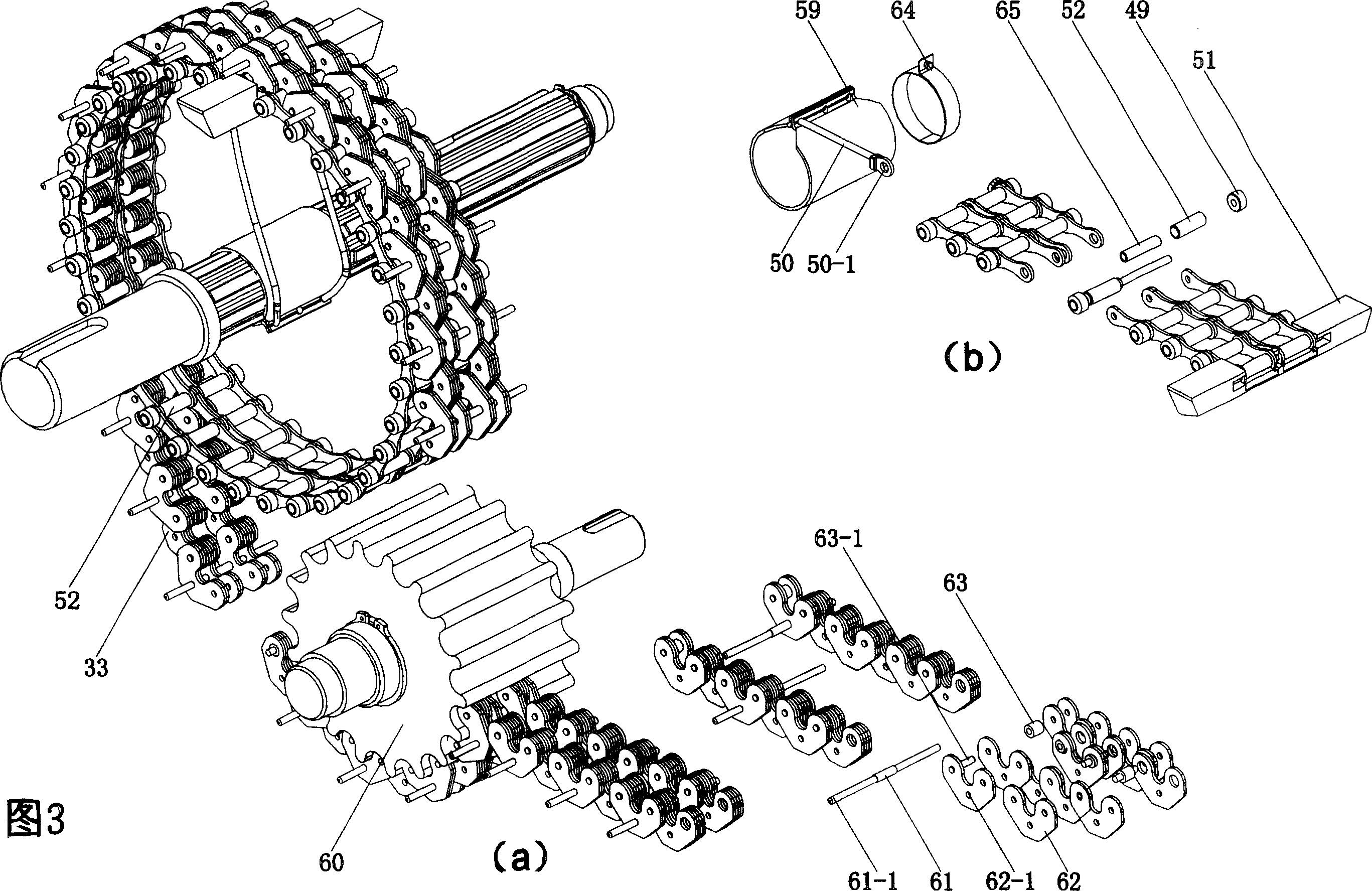

[0039] The characteristics of the variable-diameter transmission wheel, the variable-diameter transmission device and the fully automatic micro-gear transmission will be described in detail below in conjunction with the accompanying drawings.

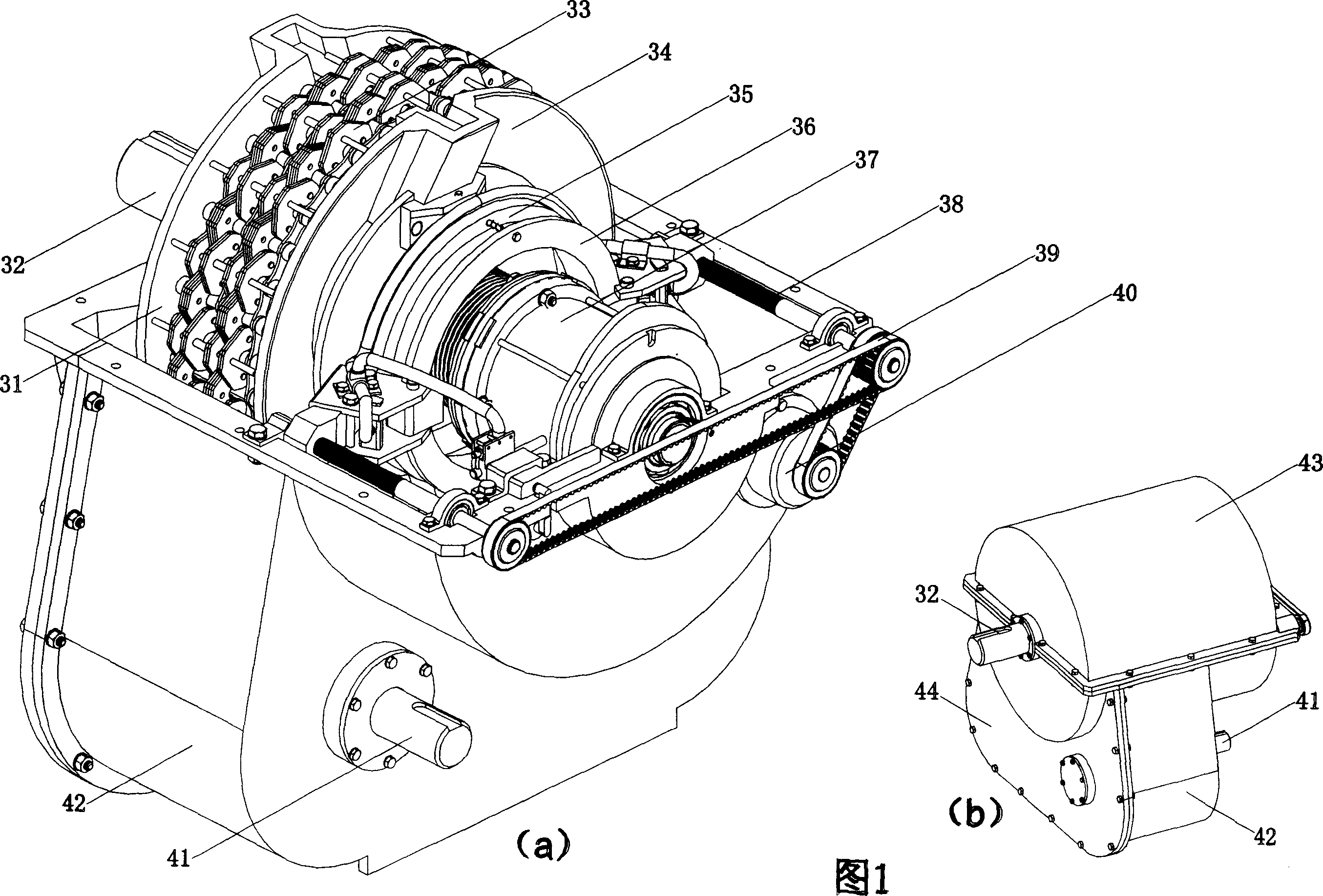

[0040]Fig. 1(a) is an assembled perspective view of an automatic transmission. The output shaft 32 is mounted on the lower housing 42; the fixed cone 31 is mounted on one end of the output shaft 32, and the spacer cylinder 37 is mounted on the other end of the output shaft 32 to play the role of fixing the axial position of the movable cone 34. There are threaded holes on the poles on both sides of the gear shifting frame 35, and the threaded rods 38 are screwed into them; when the stepping motor 40 drives a pair of threaded rods 38 to rotate through the synchronous belt 39, it can drive the gear shifting frame 35 and the gear mounted on it. The chainring 36 translates. The power transmitted by the speed changer is input by the input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com