Method for weaving braided fabric with bound edge of double sides from weft knitting machine

A technology of stitching fabrics and weft knitting machines, which is applied in weft knitting, textiles, papermaking, knitting, etc. It can solve the problems of long production cycle, complicated and expensive, and a large number of heads, so as to achieve a compact structure and improve fastness And toughness, the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention weaves the specific implementation mode and the steps of double-sided stitching on weft knitting machine as follows:

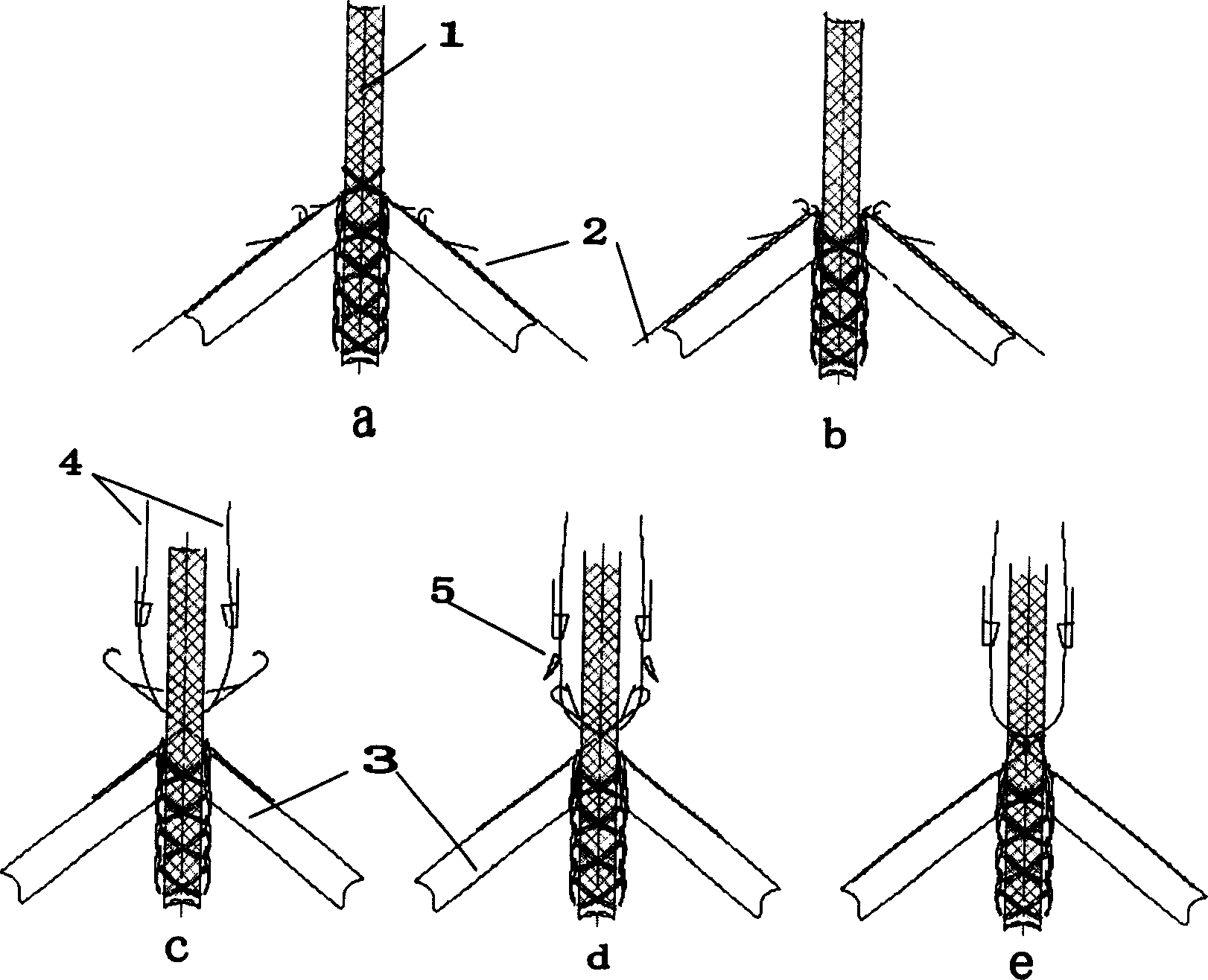

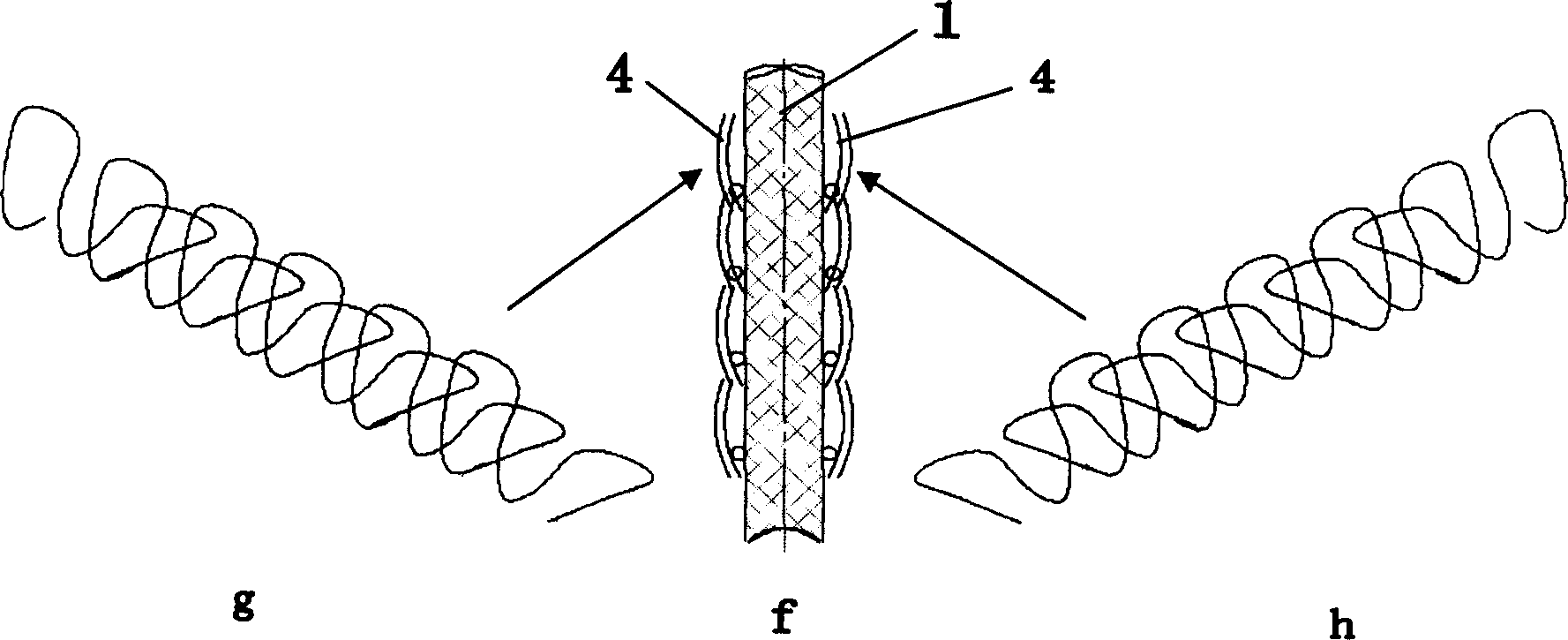

[0012] figure 1 It shows the principle diagram of weft knitting and double-sided stitch knitting of the embodiment of the present invention.

[0013] On the flat knitting machine, the stitch-bonded core layer 1 is placed in front of the needle bed 3 in such a way that the knitting needles 2 of the front and rear needle beds do not traverse laterally. All the knitting needles 2 slide up and down in the needle grooves of the respective needle beds 3 sequentially according to the weft knitting mode to complete the knitting process. In the de-knitting stage of the knitting process (figure a, b, c), the respective knitting needles 2 of the front and rear needle beds rise and penetrate through the stitched core layer 1; then the weft yarn 4 (sewing yarn) is sequentially fed The back knitting needle 2 begins to descend again, and at thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com