Technique for repairing surface damage on piston rod of hydraulic ram, and dedicated repairing tools

A technology for surface damage and hydraulic cylinders, which is applied in the field of hydraulic cylinder piston rod surface damage repair technology and its special repair tools, can solve the problems of high implementation cost, long repair cycle, laborious and laborious, etc., and achieve low work intensity and fast maintenance Fast and less impact on construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Repair process of the present invention comprises the following steps:

[0021] A. Surface treatment: Clean the damaged part of the piston rod surface with an organic solvent;

[0022] B. Overlay welding repair: use argon arc welding machine, use welding rod similar to the material of the piston rod to overlay the recessed part, and the amount of overlay welding should be 0.6-1.2mm higher than the normal circumferential surface of the piston rod;

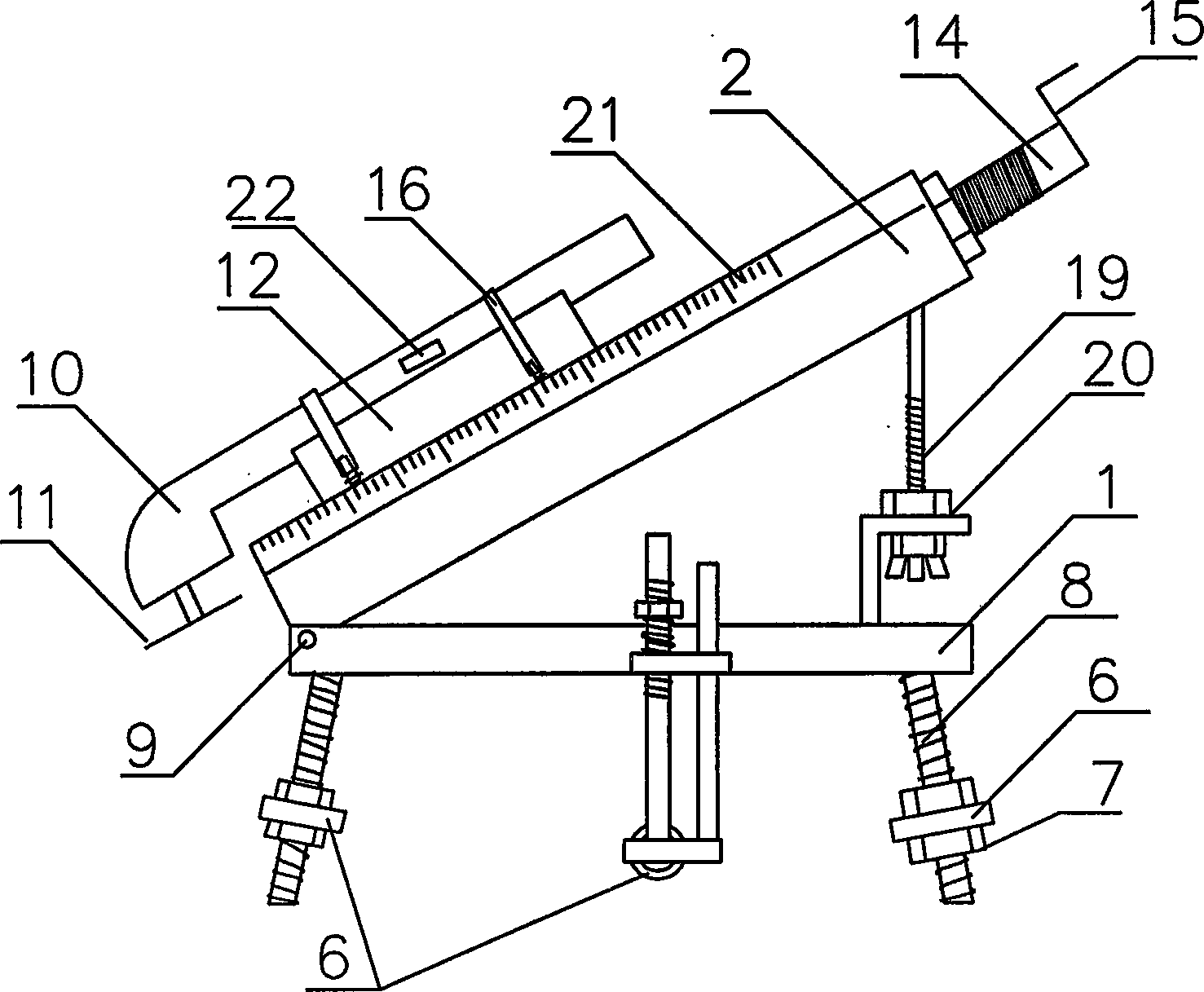

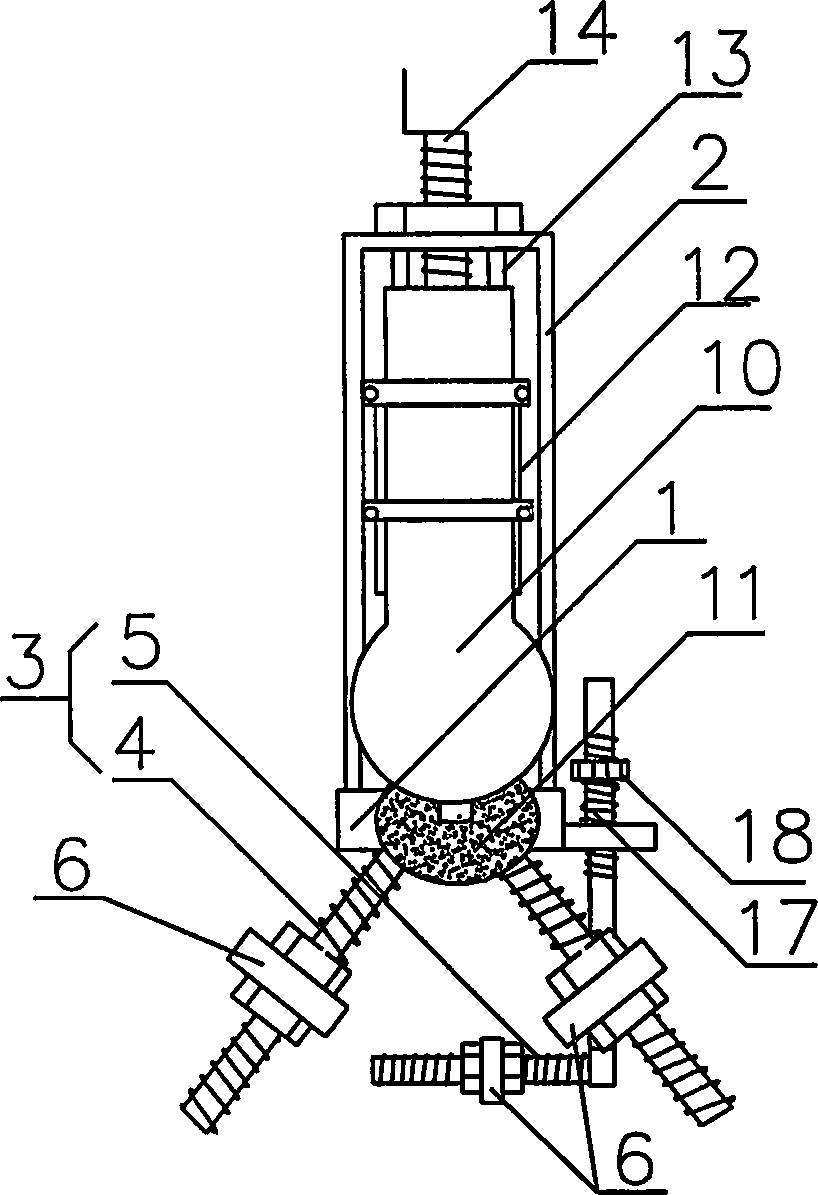

[0023] C. Grinding and arc making: use a special repair machine to grind the surfacing part along the axial and radial surfaces of the piston rod, first use a coarse grinding wheel to grind the surfacing part to 0.1-0.2mm higher than the normal circumferential surface of the piston rod, and then use a fine grinding wheel Grind the surfacing part to be level with the normal circumferential surface of the piston rod;

[0024] D. Surface polishing: Replace the fine grinding wheel of the repair machine with a coarse cloth wheel,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com