Exposure suit or downy piece of thermal underwear

A technology for thermal underwear and cold-proof clothing, applied in underwear, protective clothing, clothing, etc., can solve the problems of poor thermal performance and uneven thickness, and achieve the effect of good air permeability and thermal retention, advanced processing methods, and slender fluff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

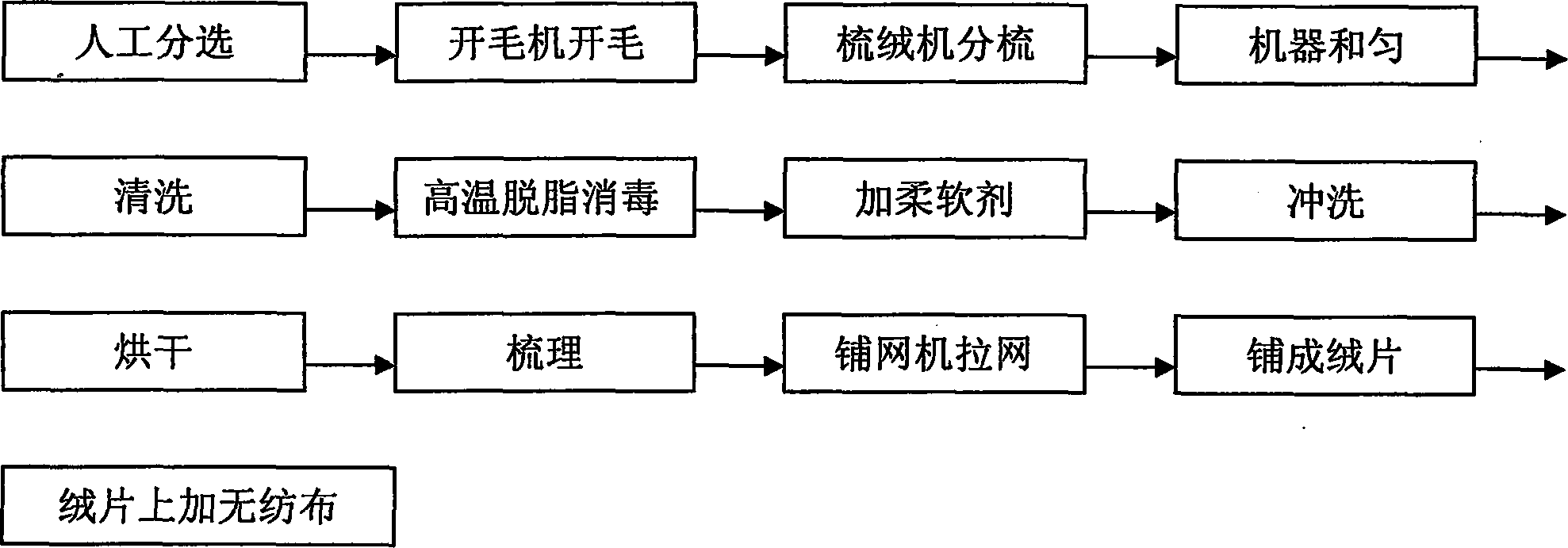

[0015] figure 1 Among them, a processing method of fleece for cold-proof clothing or thermal underwear is: after purchasing raw materials, manually sorting, sorting out white hair, black hair, patterned hair, and dead hair; Hair, carded 5-6 times with self-modified 181 and 186 carding machines, the carded plush is evenly blended by the machine, washed after blending, degreased and sterilized at high temperature, softened with softener and rinsed completely , dry; enter the carding machine again for carding; use the netting machine to pull 8-10 layers of plush nets, and spread them into fluff pieces of various weights and widths. Plus the qualified cashmere sheets of non-woven fabrics, and provide them to the required factory; the cashmere sheets processed by the above method can be cashmere, camel, yak, alpaca, rabbit Cashmere flakes, cashmere flakes, wool flakes; cashmere flakes can be mixed cashmere and sheep cashmere flakes; yak fluff flakes can be flakes mixed with yak ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com