Trielement synergistic corrosion inhibitor

A technology of corrosion inhibitor and water treatment agent, used in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as a large number of fresh water replacement, and reduce blindness and experience. , Good corrosion and scale inhibition performance and small dosage of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

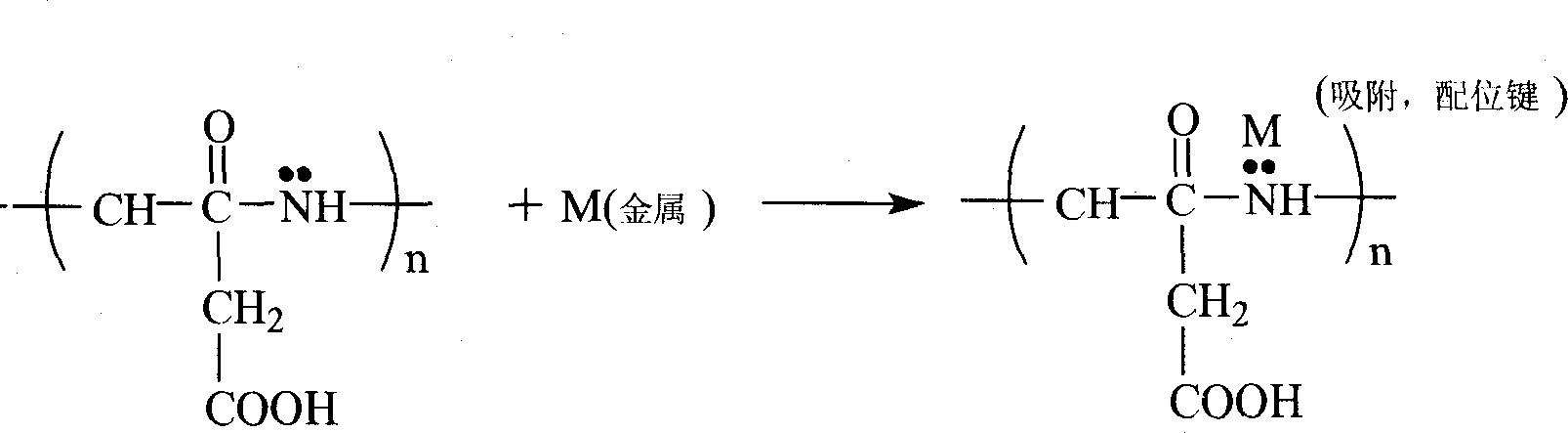

Method used

Image

Examples

Embodiment 1

[0020] According to the formula of the present invention, the water treatment agent is prepared by conventional methods. According to the HG / T2159-91 standard, fix the standard A3 steel test piece on the test piece frame of the dynamic corrosion tester, and directly put it into the test piece with PASP30mg / L, zinc chloride 3mg / L (Zn 2+ meter), PBCTA20mg / L and standard corrosion water (containing calcium chloride dihydrate 735mg / L, magnesium sulfate 493mg / L, sodium chloride 658mg / L and sodium bicarbonate 168mg / L) in a test cup, the test cup is placed In a constant temperature water bath at 40°C, the test piece rotates at a speed of 0.35m.S-1, the test solution evaporates naturally, and water is replenished every 4h, and the test is stopped after 72h. The measured corrosion rate of the standard A3 steel test piece is 0.050mm / a .

Embodiment 2

[0022] The operating method is the same as in Example 1, and the sodium polyaspartate is substituted for PASP (consumption is calculated in PASP), and the remaining conditions are the same as in Example 1. The measured corrosion rate of the standard A3 steel test piece is 0.052mm / a.

Embodiment 3

[0024] The operating method is the same as in Example 1, and the calcium polyaspartate is substituted for PASP (consumption is calculated in PASP), and the remaining conditions are the same as in Example 1. The measured corrosion rate of the standard A3 steel test piece is 0.056mm / a.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com