Sewage treatment technology process and equipment

A technology for wastewater treatment and process flow, applied in biological water/sewage treatment, water/sludge/sewage treatment, aerobic process treatment, etc. The process is stable and reliable, the maintenance cost is reduced, and the oxygen supply is sufficient.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] This example is the experimental equipment and process flow of wastewater treatment in a rice noodle factory. The main pollutants in the wastewater are shown in Attached Table 1.

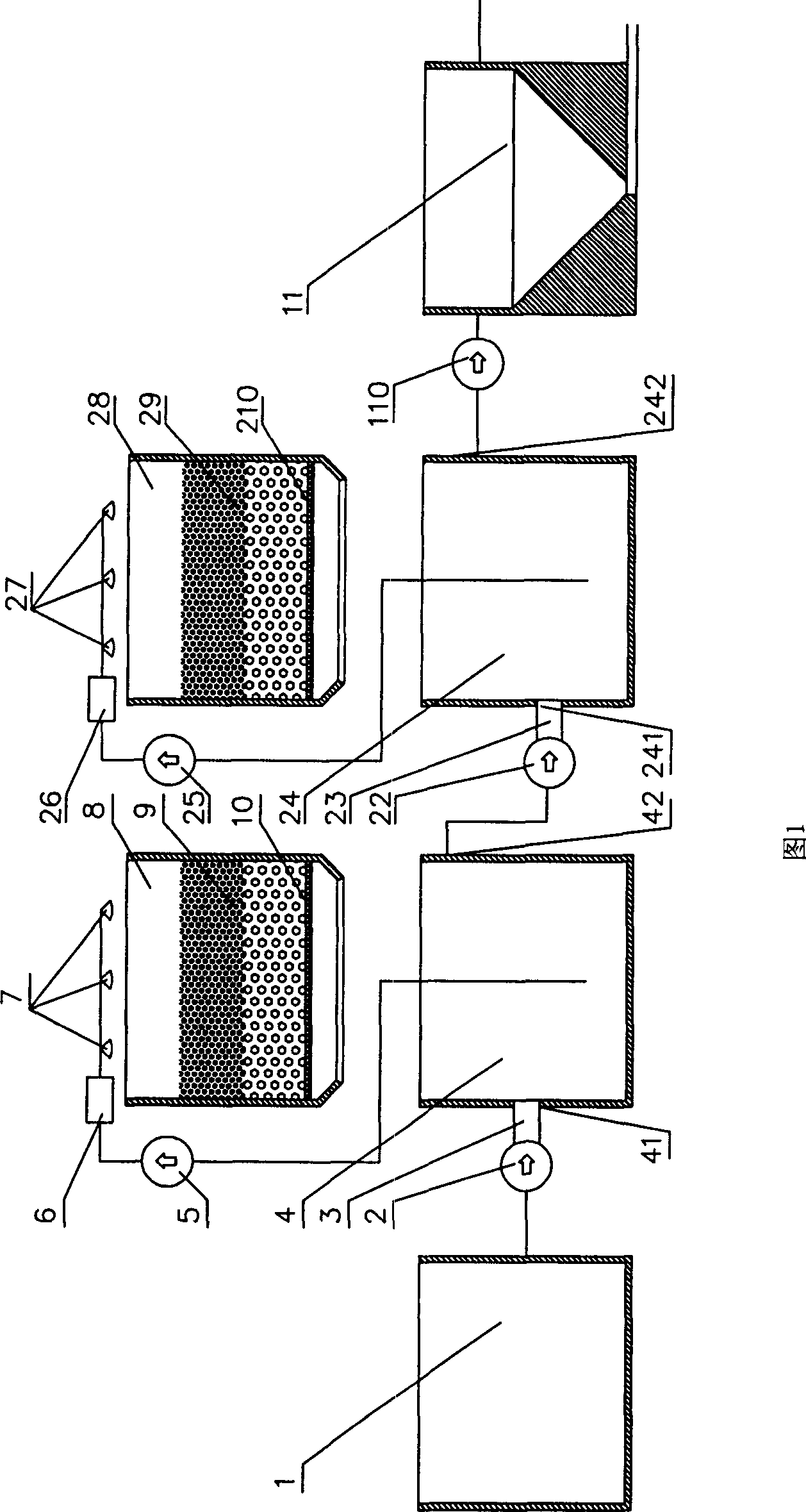

[0032] The experimental equipment of wastewater treatment described in this embodiment is as figure 1 As shown, the process adopts a two-stage series working mode, and the design flow rate of sewage treatment is: 3M 3 / h.

[0033] The wastewater treatment equipment described in this embodiment includes a sewage tank 1, a first-stage swirl spray tank 4, a first-stage microbial treatment tank 8, a second-stage swirl spray tank 24, a second-stage microbial treatment tank 28, a desliming Pool 11 etc., its structure is as figure 1 shown.

[0034] The sewage pool 1 is the sewage pool in the prior art, which is used to adjust the peak flow of sewage and balance the fluctuation of sewage concentration.

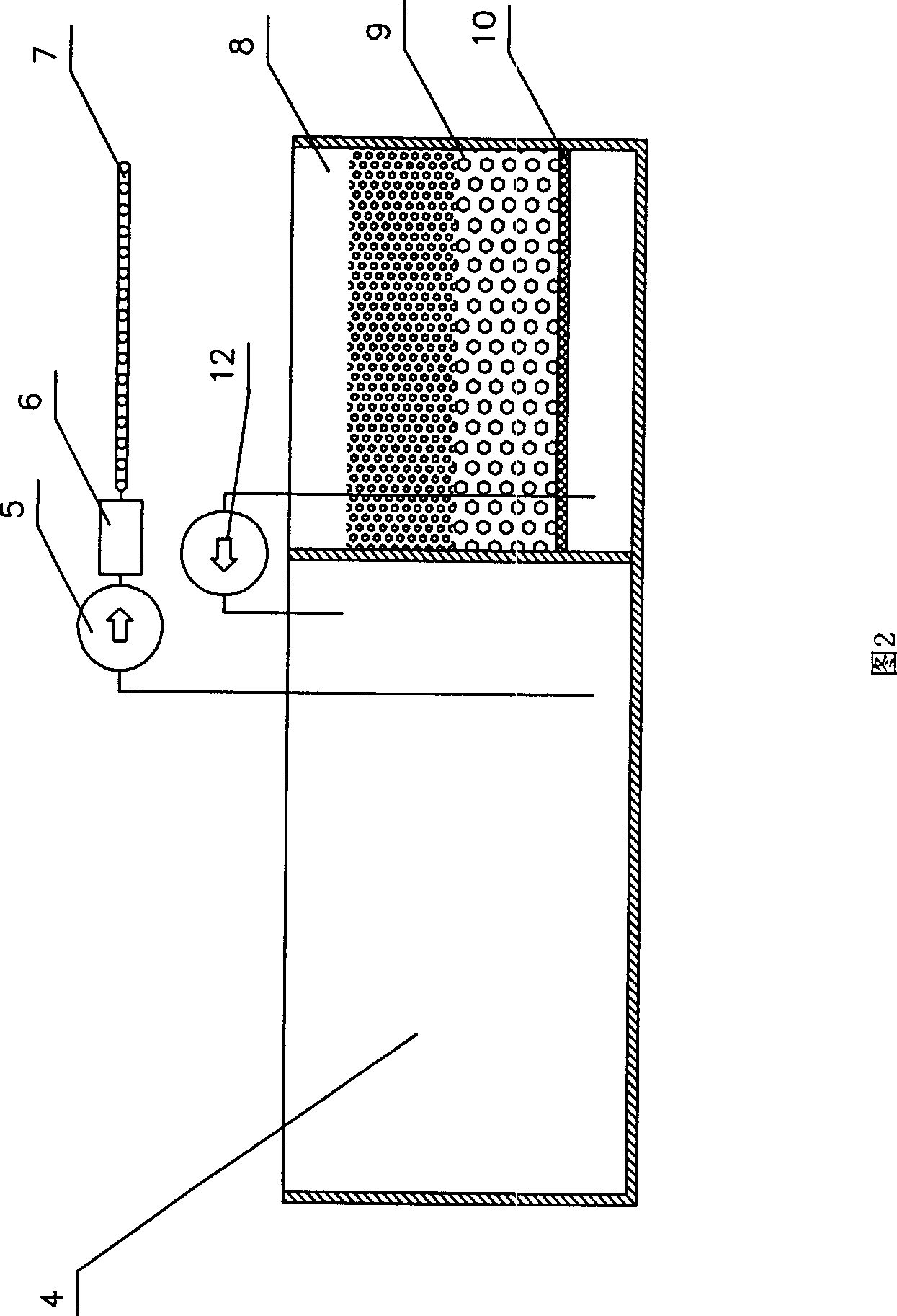

[0035] The inside of the first stage swirl jet tank 4 is cylindrical, and its effective volum...

Embodiment 2

[0065] This example is a design scheme for the transformation of wastewater treatment facilities in a pig farm. In view of the quality of wastewater, the wastewater treatment equipment and process described in this example adopt a four-stage series working mode, and the designed daily treatment capacity is: 100m 3 / sky.

[0066] The waste water treatment equipment described in this embodiment is to transform the original four waste water treatment ponds, one waste water pond and one desilting pond on site to form a waste water pond, a first-stage aeration tank, that is, a first-stage swirl spray tank 4. The first-stage microbial treatment tank 8. The second-stage aeration tank is the second-stage swirl jet tank, the second-stage microbial treatment tank, the third-stage aeration tank is the third-stage swirl jet tank, and the third-stage Microbial treatment tanks, fourth-stage aeration tanks, namely fourth-stage swirl jet tanks, fourth-stage microbial treatment tanks, desiltin...

Embodiment 3

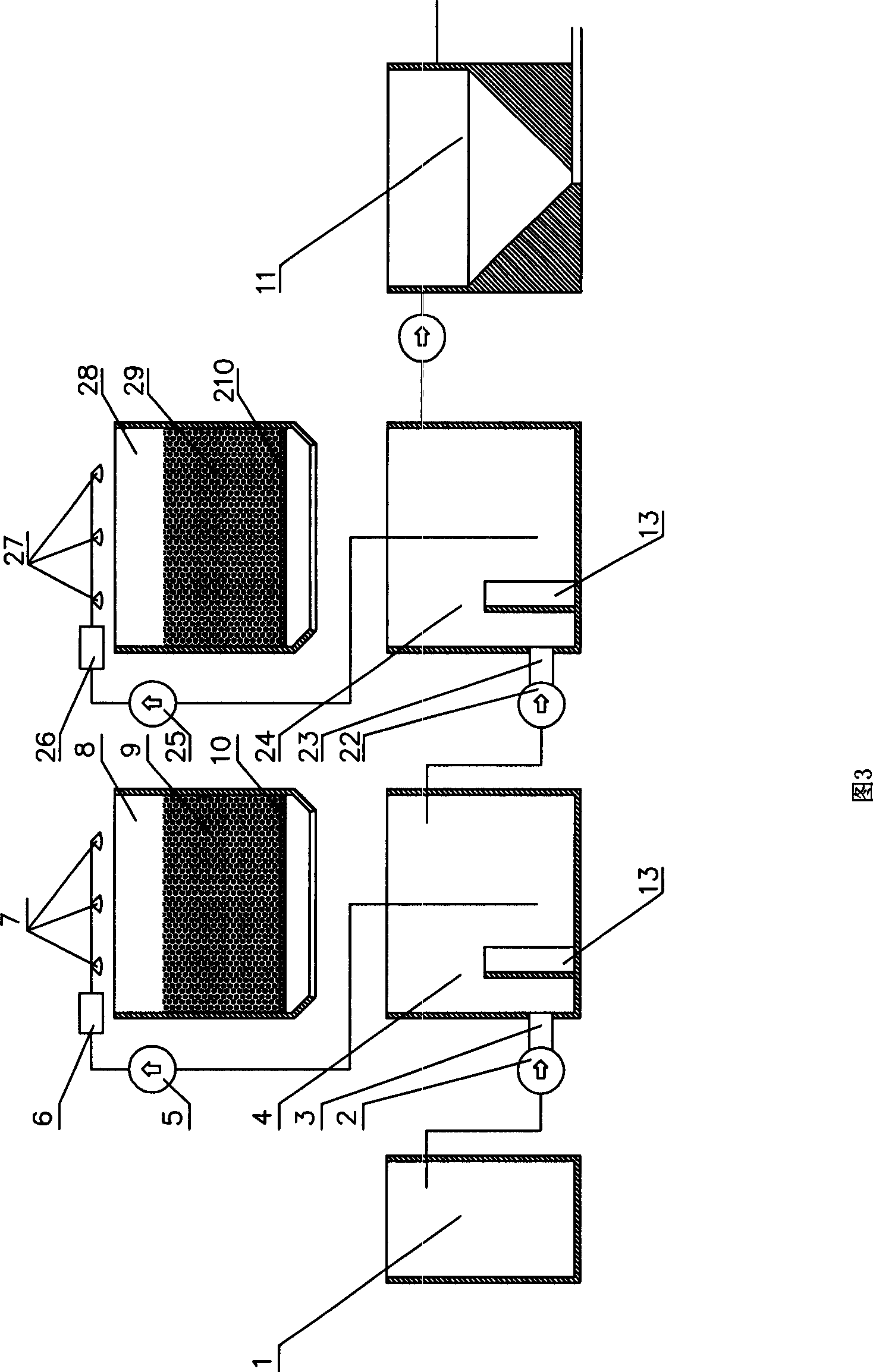

[0089] The wastewater treatment equipment and technological process described in this embodiment are suitable for large-scale urban wastewater treatment plants, adopting a two-stage series working mode, and the designed flow rate is: 100,000 cubic meters per day.

[0090] The wastewater treatment equipment described in this embodiment includes a sewage tank 1, a first-stage swirl spray tank 4, a first-stage microbial treatment tank 8, a second-stage swirl spray tank 24, a second-stage microbial treatment tank 28, a desliming pool 11 etc., see image 3 , wherein the sewage pool 1 is the sewage pool in the prior art, which is used to adjust the peak flow of sewage and balance the fluctuation of sewage concentration.

[0091] The inside of the first-stage swirl spray tank 4 is cylindrical, and its effective volume is 80,000 cubic meters. There are 15 source water inlets evenly distributed on the bottom of its side wall, and 15 source water inlets are evenly distributed on the top...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com