Conveyor chain

一种传送链、链节的技术,应用在传送链领域,能够解决传送面高度变动、传送带模块与滚珠滑动磨损、难以稳定传送物品等问题,达到抑制高度的变动、防止破损及变形、抑制旋转不良的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

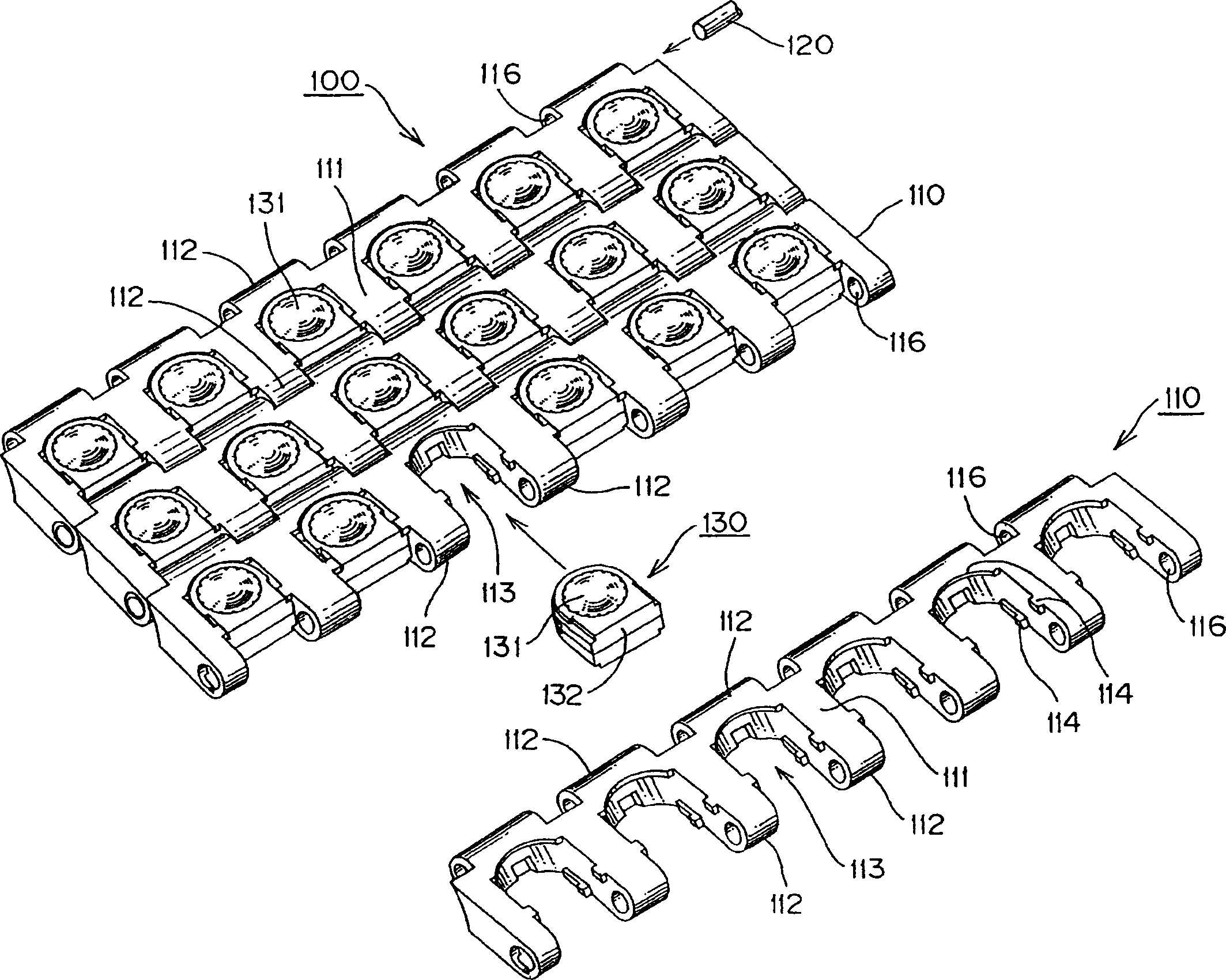

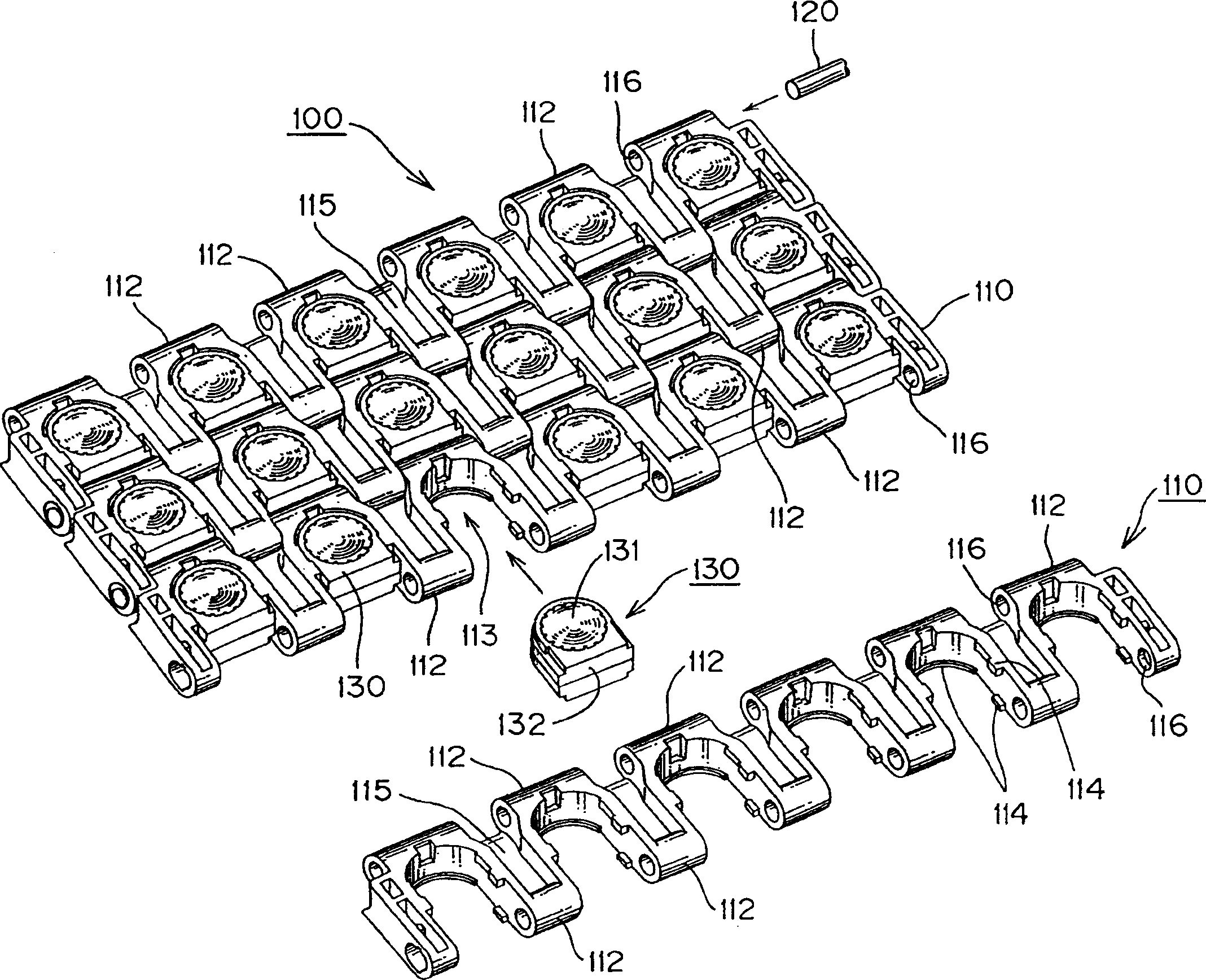

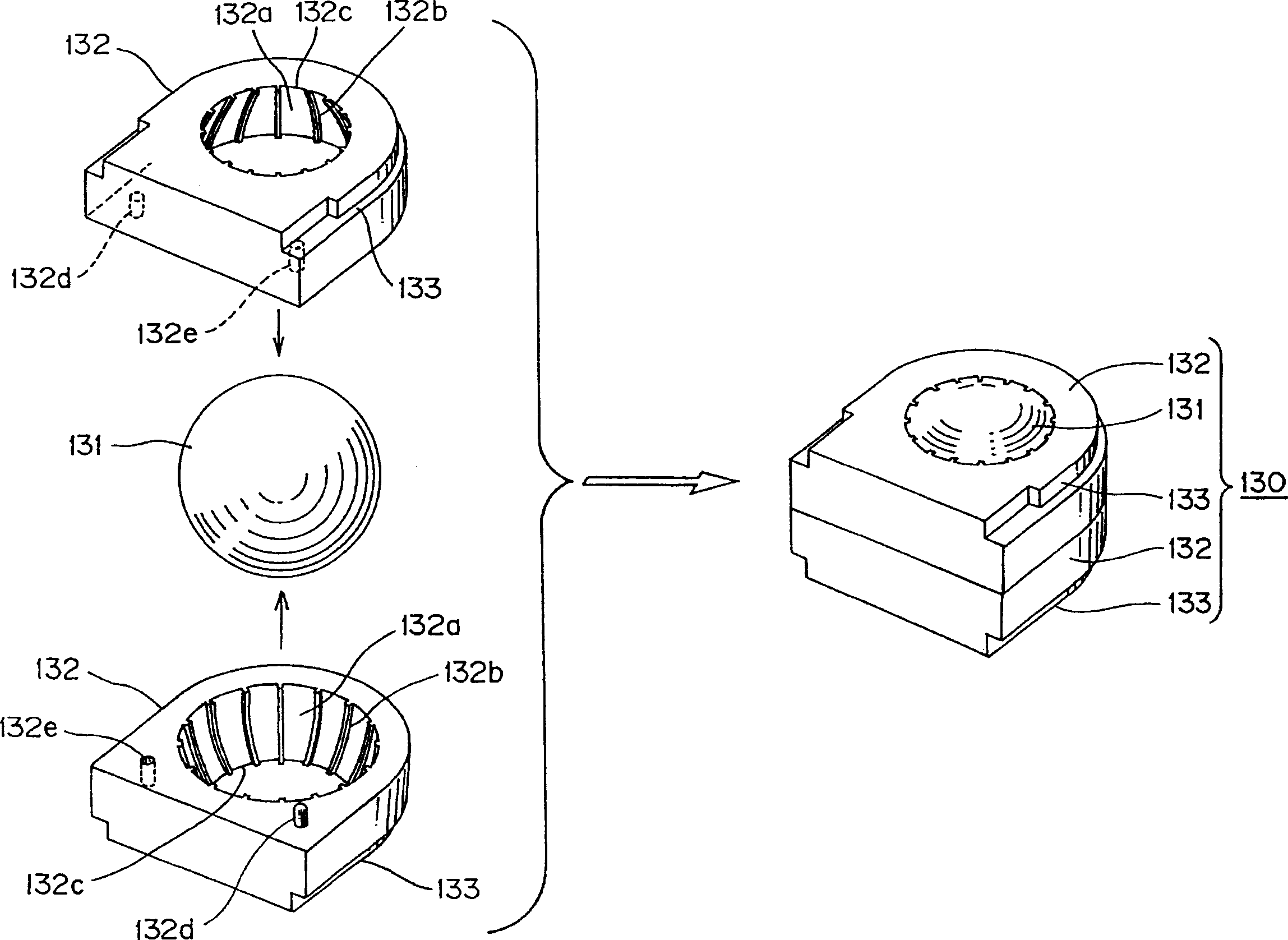

[0025] The present invention is a conveyor chain, wherein, a plurality of chain links with a plurality of hinge parts protruding alternately from the front end edge and the rear end edge are respectively connected in the length direction of the chain by means of hinge pins, and the front and back sides of the aforementioned chain links The protruding free balls are rotatably held by the links, wherein either one of the free balls and a ball holding portion holding the free balls is made of polyacetal, and the other is made of polyamide or polyester. Formed, thus, the free balls held in the conveyor chain can be rotated in all directions, thereby exerting the function of changing the direction of conveyance and the function of double speed that can be conveyed in the entire 360-degree horizontal plane, and can suppress the wear of the free balls and ball holding parts, Thus, stable transmission can be performed, and if it is such a device, its specific form can be arbitrary.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com