Light emitting tube array type display unit and driving method thereof

A technology of a display device and a driving method, which is applied to alternating current plasma display panels, discharge tubes, identification devices, etc., can solve the problems of high discharge voltage, high shading rate, and deviation of discharge starting voltage, and achieves reduction in number and shading rate. , the effect of reducing the discharge voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

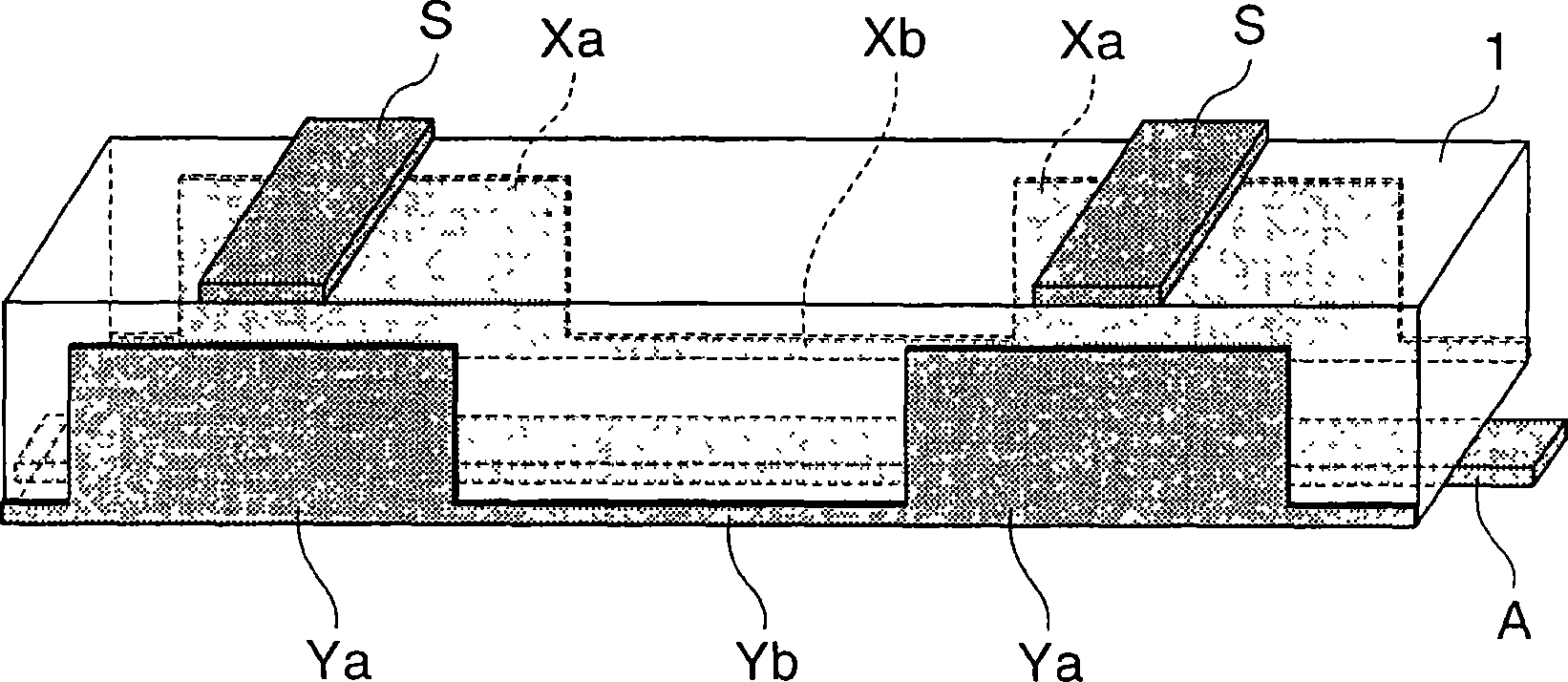

[0032] In the arc tube array type display device of the present invention, any type of arc tube array can be used as long as it has a structure in which a plurality of arc tubes are arranged side by side, and each arc tube has an arc tube sealed therein. discharge gas. As the thin tube forming the body of the arc tube, any thin tube having any diameter may be used, and those made of glass having a diameter ranging from 0.5 to 5 mm are preferably used. As for the shape of the thin tube, any cross-sectional shape such as a circular cross-section, an elliptical cross-section, and a rectangular cross-section can be used.

[0033]As the supporting member, any member may be used as long as it is brought into contact with at least one of the display surface side and the rear surface side of the arc tube array and it can support the arc tube array. For example, both a film made of resin and a substrate made of glass can be used as the supporting member. As the film made of resin, fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com