Magnetic thin film for high frequency and its production method, and magnetic element

A technology of magnetic thin film and manufacturing method, applied in the direction of magnetic thin film, application of magnetic film to substrate, magnetic layer, etc., can solve the problem that magnetic thin film cannot be said to be very suitable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

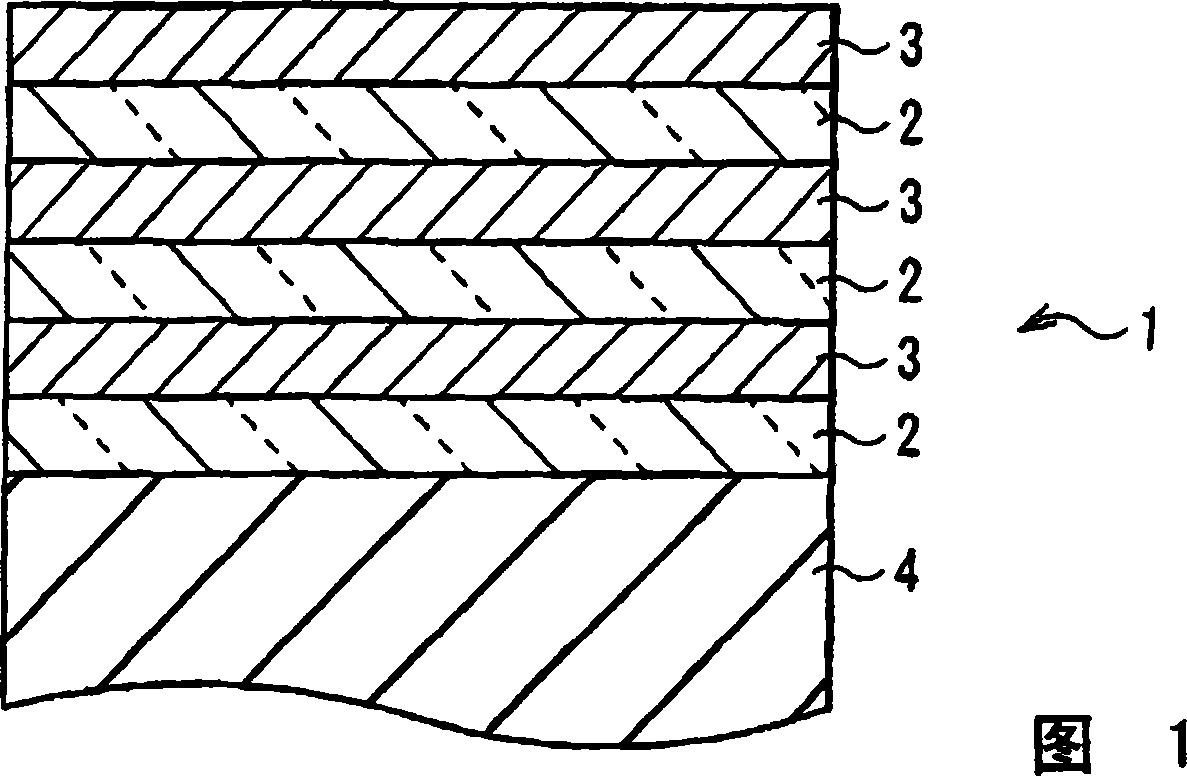

Image

Examples

Embodiment 1

[0079] The high-frequency magnetic thin film of Example 1 was prepared by the following film-forming method.

[0080] First, SiO was formed on a Si wafer with a thickness of 500nm 2 The film is used as a substrate. Then, a magnetic thin film for high frequency use was formed (deposited) on the substrate in the following manner using an opposed target sputtering apparatus. That is, pre-exhaust the opposing target sputtering device until 8×10 -5 After Pa, Ar gas was introduced until the pressure reached 10 Pa, and the substrate surface was sputter-etched with 100 W of RF power for 10 minutes. Next, adjust the Ar gas flow rate so that the pressure reaches 0.4Pa, and sputter Co with a power of 300W. 87 Zr 5 Nb 8 target, produced a Co 87 Zr 5 Nb 8 composed of amorphous films.

[0081] Next, a native oxide layer is formed. The natural oxide layer was formed as follows: After forming each metal layer, 2 sccm of O was introduced into the sputtering device. 2 gas for 30 seco...

Embodiment 2

[0086] Based on the film-forming method of the above-mentioned Example 1, the 2.3nm thick CoZrNb and the 1.0nm natural oxide layer were alternately formed 121 times each, forming a magnetic thin film with a total film thickness of 400nm (corresponding to a total of 242 layers) ( Example 2). At this time, the proportion of the native oxide layer in the volume of the entire multilayer film was 30%.

[0087] Table 1 shows the magnetic properties of the obtained magnetic thin film. The saturation magnetization 4πMs is 0.80T (= 8.0kG), the coercive force Hce in the direction of the easy axis of magnetization is 1400A / m (= 17.6Oe), and the coercive force Hch in the direction of the hard axis of magnetization is 2950A / m (= 37Oe). In the high-frequency magnetic permeability characteristic, the value of the real number part (μ1) of the magnetic permeability was 40 at 1.0 GHz, and the resistivity was 860 μΩcm.

Embodiment 3

[0089] Based on the film formation method of Example 1 above, after forming a 1.6 nm thick CoZrNb layer, introduce 5 sccm of O into the sputtering device. 2 The gas was used for 30 seconds to oxidize the surface of the metal layer, thereby forming a natural oxide layer of 1.3 nm. CoZrNb layers with a thickness of 1.6 nm and natural oxide layers with a thickness of 1.3 nm were alternately and sequentially formed 138 times each to form a magnetic thin film with a total film thickness of 400 nm (corresponding to a total of 276 layers) (Example 3). At this time, the proportion of the native oxide layer in the volume of the entire multilayer film was 45%.

[0090] Table 1 shows the magnetic properties of the obtained magnetic thin film. The saturation magnetization is 0.63T (= 6.3kG), the coercive force Hce in the direction of the easy axis of magnetization is 1750A / m (= 22Oe), and the coercive force Hch in the direction of the hard axis of magnetization is 3260A / m (= 41Oe). In t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com