Sealing device of proton exchanging film fuel cell unit

A fuel cell unit and proton exchange membrane technology, applied in fuel cell components, fuel cells, solid electrolyte fuel cells, etc., can solve the problems of aging failure of gaskets, gas leakage, unstable balance, etc., and achieve good air tightness performance, long battery life, and tight sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

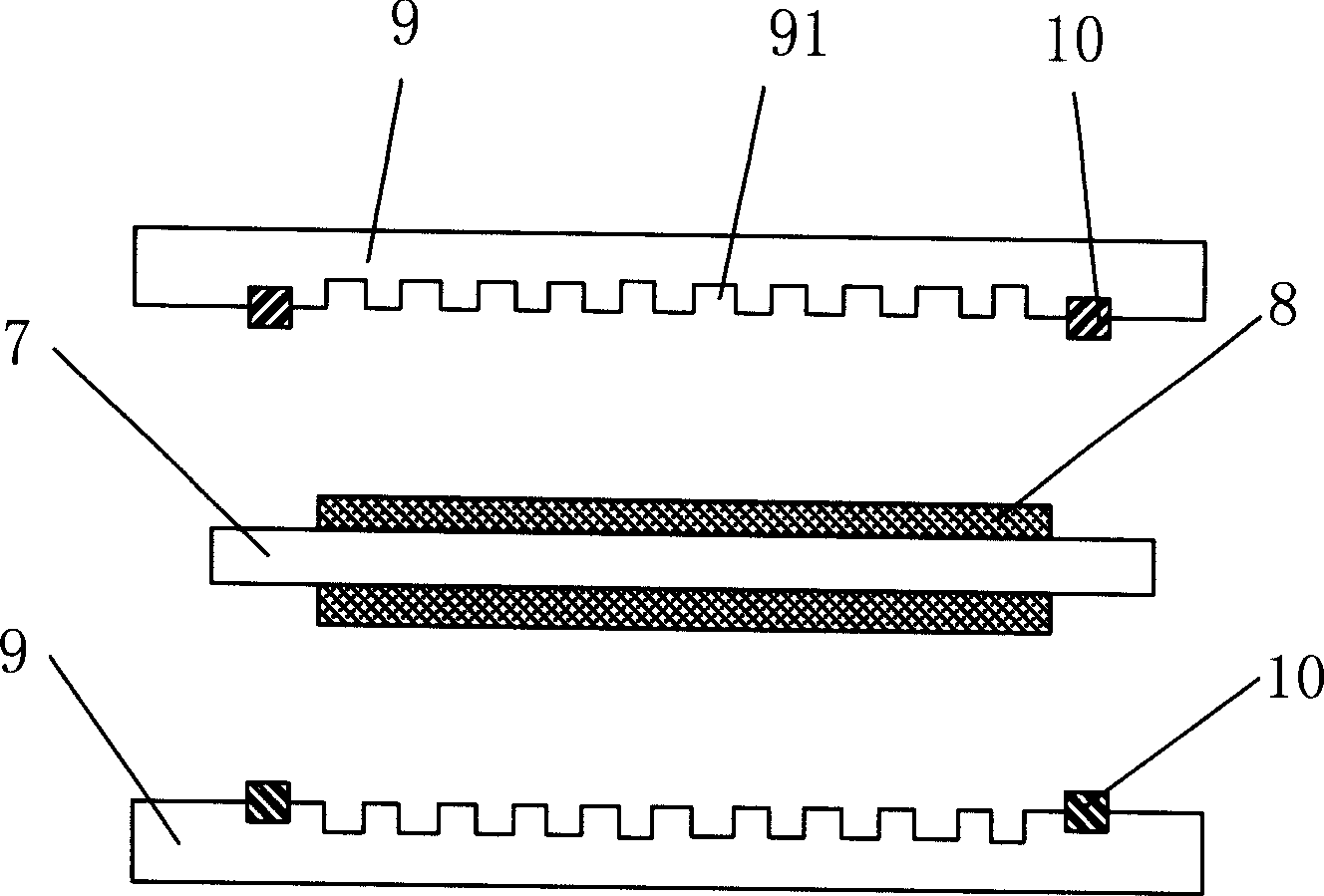

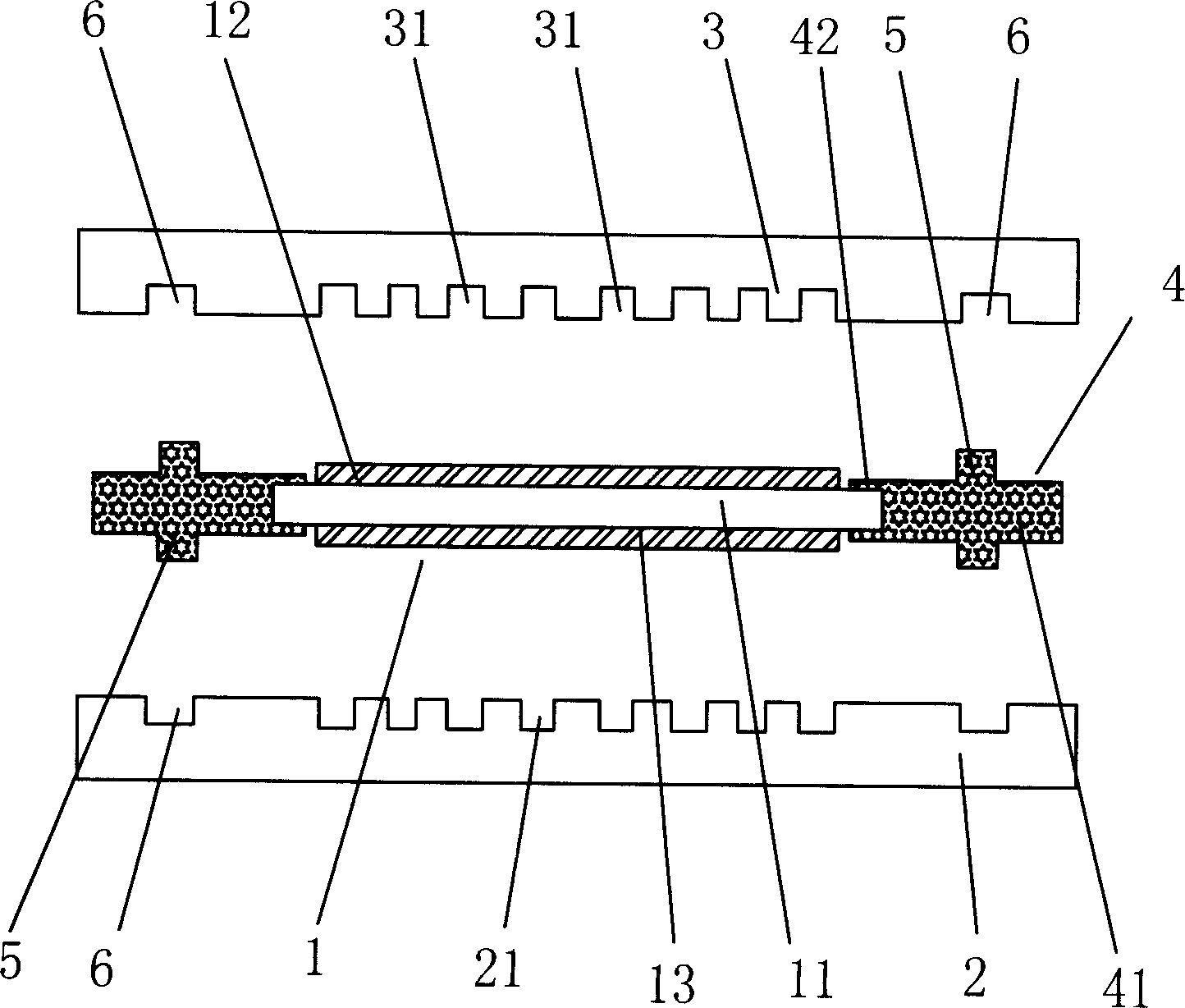

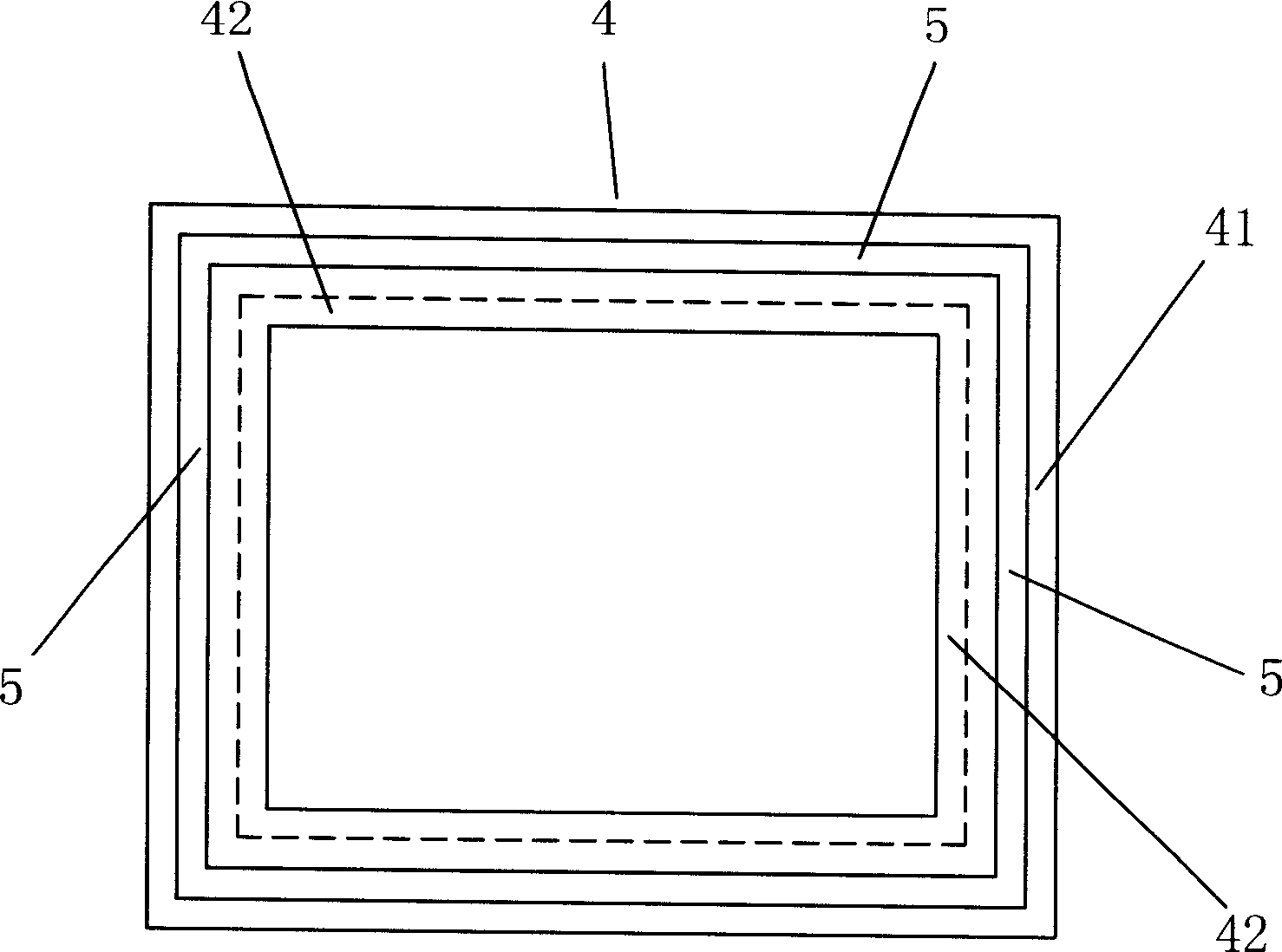

[0026] see Figure 2 to Figure 5 The sealing device of the proton exchange membrane fuel cell unit of the present invention includes a membrane electrode assembly 1 and a cathode guide plate 2 and an anode guide plate 3 sandwiching the membrane electrode assembly. The membrane electrode assembly 1 comprises a proton exchange membrane 11 and a cathode 13 and an anode 12 attached to both sides of the proton exchange membrane 11 in the longitudinal direction. The proton exchange membrane 11 is made of a polymer material, such as the existing DuPont Nafion membrane. The anode 12 and the cathode 13 are all made of porous and conductive materials. In this embodiment, the anode 12 and the cathode 13 are all porous carbon paper or carbon cloth. In the longitudinal direction, the proton exchange membrane 11 It is 0.1%-80% longer than the length of the porous carbon paper or carbon cloth.

[0027] The cathode guide plate 2 and the anode guide plate 3 are provided with several guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com