Microwave heating oil-free directly igniting burner for pulverized-coal fired boiler

An ignition burner, microwave heating technology, applied in burners, burners burning powder fuel, combustion ignition and other directions, can solve the problems of large maintenance workload of fuel system, reduce power generation economy, increase power generation cost, etc. Long-term stable operation, small daily maintenance, and fuel saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

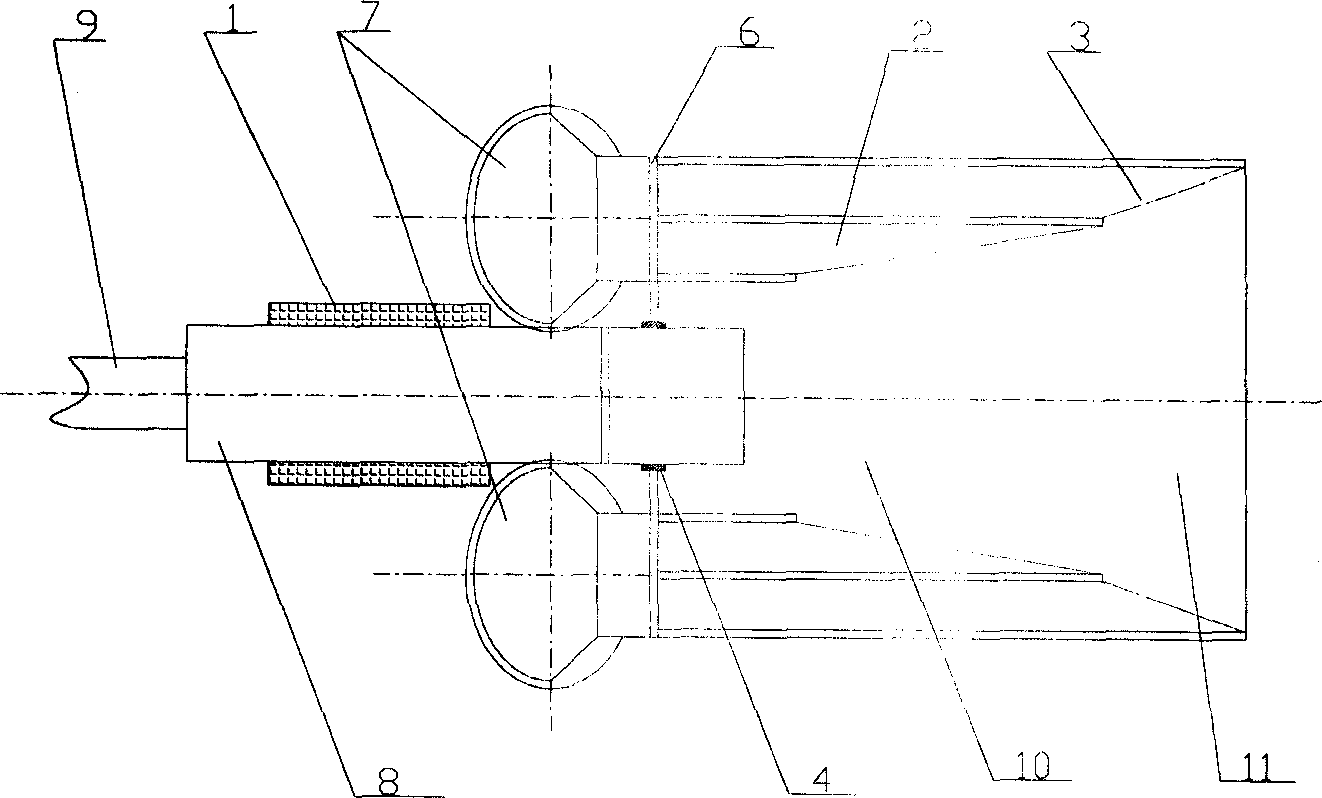

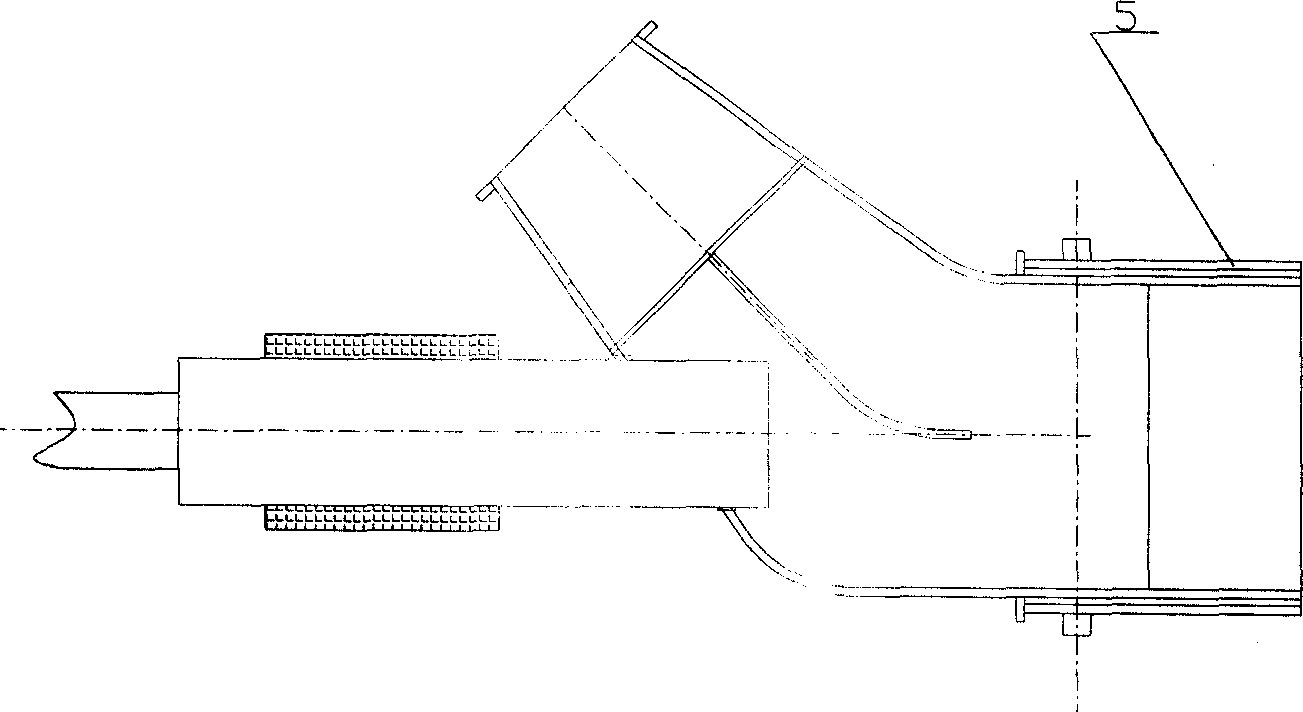

[0014] A pulverized coal boiler microwave heating oil-free direct ignition burner, it has a power supply system, cooling water system and igniter body, such as figure 1 , figure 2 As shown, the igniter body has the first stage of the igniter, the second stage of the igniter, and the third stage of the igniter. A microwave heating layer (1) is provided on the outside, and a sealing gasket (4) is provided outside the outlet of the pipe body (8). The pulverized coal outlet (2), the third stage of the igniter has a third stage ignition chamber (11), the third stage pulverized coal outlet (3), the second stage igniter and the third stage igniter are arranged inside the pulverized coal splitter plate (6), and the third stage The secondary air chamber (5) is arranged at the outlet of the primary igniter.

[0015] The power supply system adopts adjustable alternating current, and microwaves are generated by the power supply to heat the tube body 8 sections or the whole section.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com