Modular structural supporter containing damping filling materials

A filling material and modular technology, applied in the direction of machine/support, supporting machine, instrument parts, etc., can solve the problems of inability to effectively reduce the weight per unit area of the platform, increase manufacturing costs, and poor rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

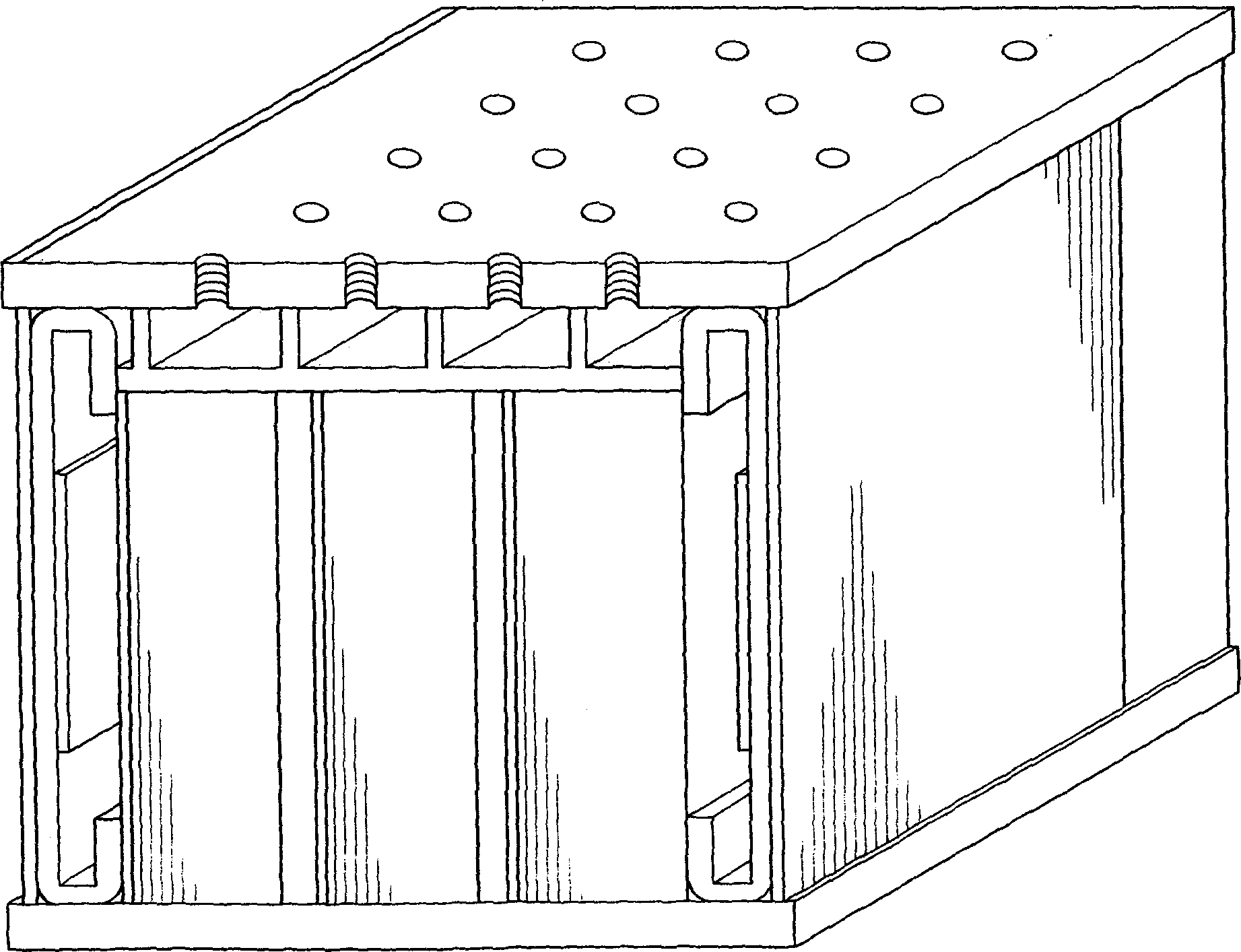

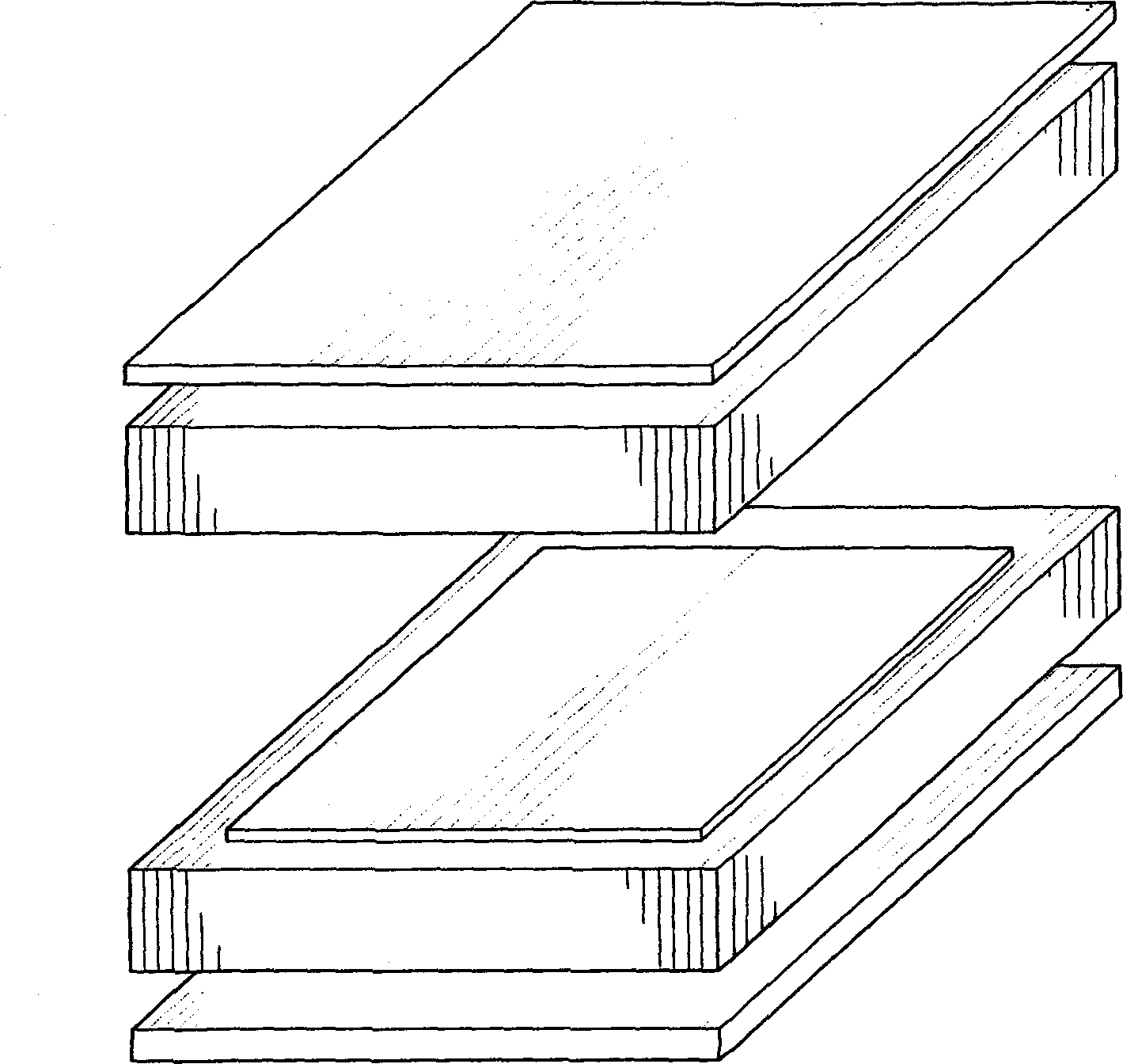

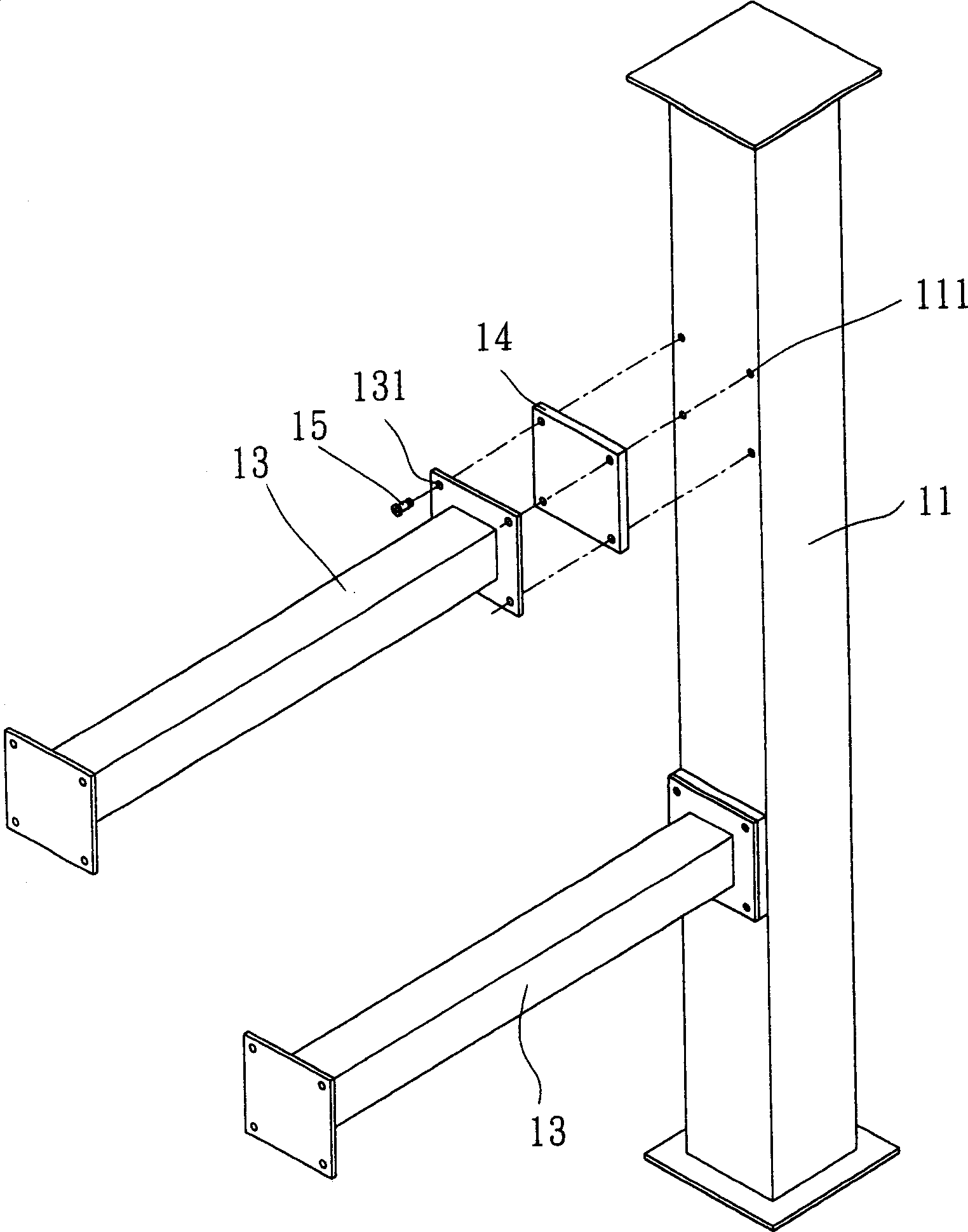

[0020] see image 3 , Figure 4 , Figure 5 , the present invention is mainly applied to the bearing platform supporting frame of high-precision process equipment and testing equipment. The supporting frame is filled with fillers 12 (such as light epoxy resin, foaming material, etc.) or polyurethane (PU) and other damping materials) to reduce the weight of each first support member 11 and provide sufficient damping effect, on the premise that the first support member 11 can effectively reduce the weight, the first support member 11 can use a relatively Big size, to increase the rigidity of structure, another second supporting member 13, it can be solid or tubular hollow bar, when being tubular hollow bar, its inside then is filled with filler 12 equally (as light weight Epoxy resin, foam material or PU and other damping materials) to reduce the weight of each second support member 13 and provide sufficient damping effect; the first support member 11 and the second support me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com