Vibration-proof worktable for adjusting levelness of microscope and mounting method of vibration-proof worktable

A microscope and leveling technology, applied in microscopes, optics, instruments, etc., can solve the problems of optical path affecting use, stage drift, irresponsible manufacturing, etc., and achieve the effect of prolonging service life, improving leveling, and reducing micro-vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, exemplary embodiments of the present invention will be described in further detail with reference to the accompanying drawings.

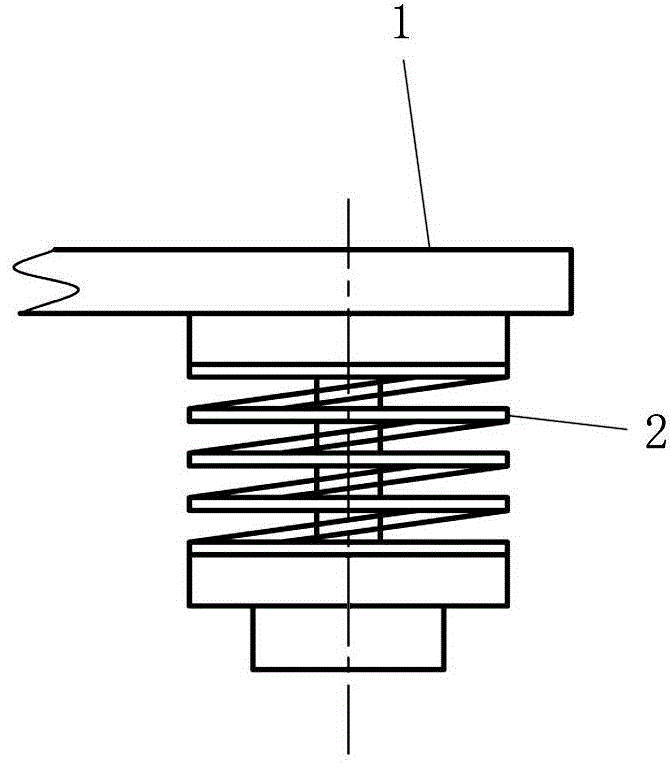

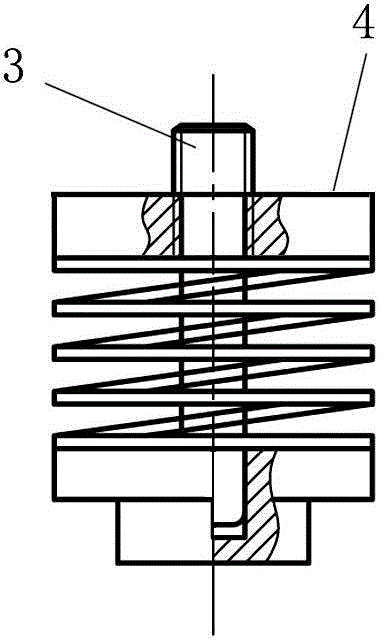

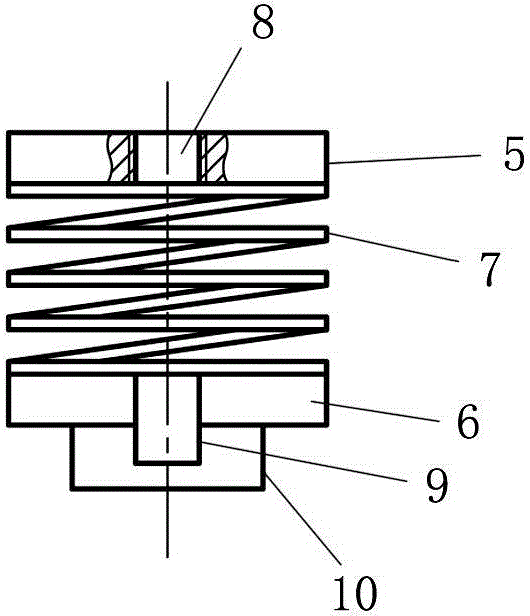

[0026] Figure 1A It is a schematic diagram of the assembly structure of the anti-vibration workbench for adjusting the horizontality of the microscope according to the exemplary embodiment of the present invention, Figure 2A It is a top view of the support base plate of the anti-vibration workbench for adjusting the level of the microscope according to the exemplary embodiment of the present invention, Figure 2B It is a side view of the support base plate of the anti-vibration workbench for adjusting the level of the microscope according to the exemplary embodiment of the present invention. It should be pointed out that in the present invention, shock absorption can also be referred to as shock absorption. Such as Figure 1A As shown, the anti-vibration workbench for adjusting the level of the microscope in this embodiment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com