Cast-in-place concrete hollow plate

A technology of cast-in-place concrete and hollow slabs, which is applied in the field of cast-in-place concrete hollow slabs, and can solve problems such as installation difficulties and troublesome repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

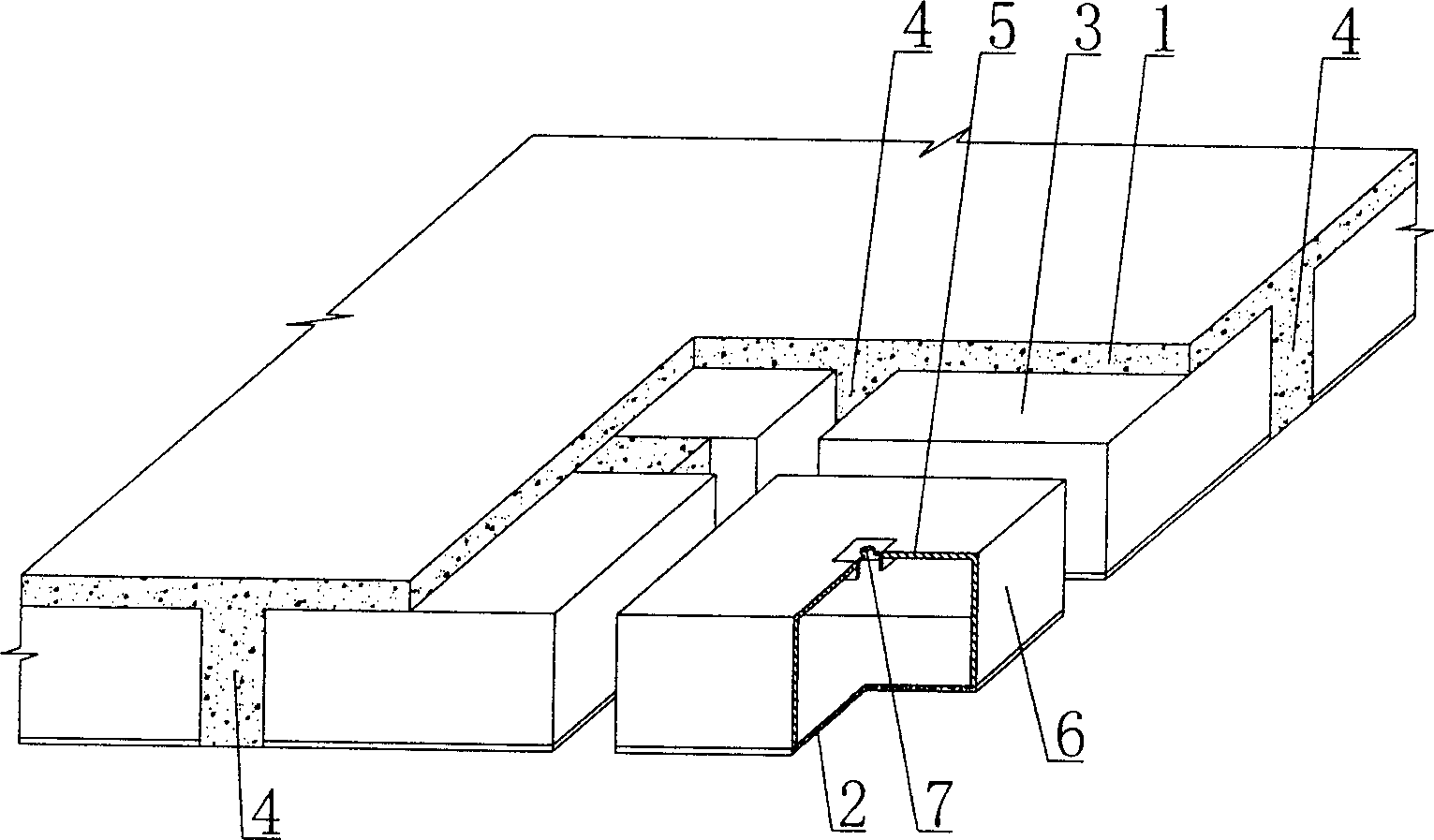

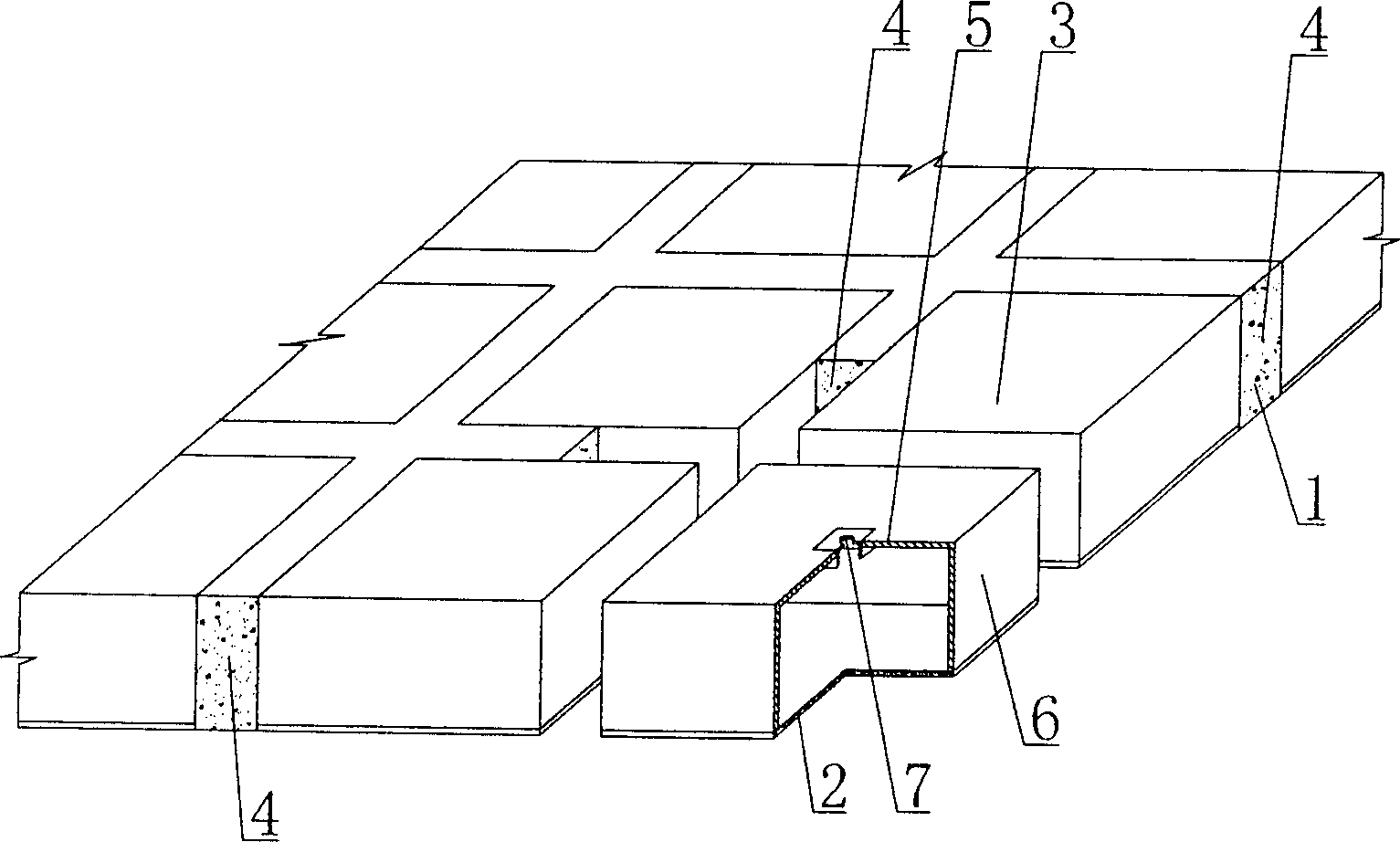

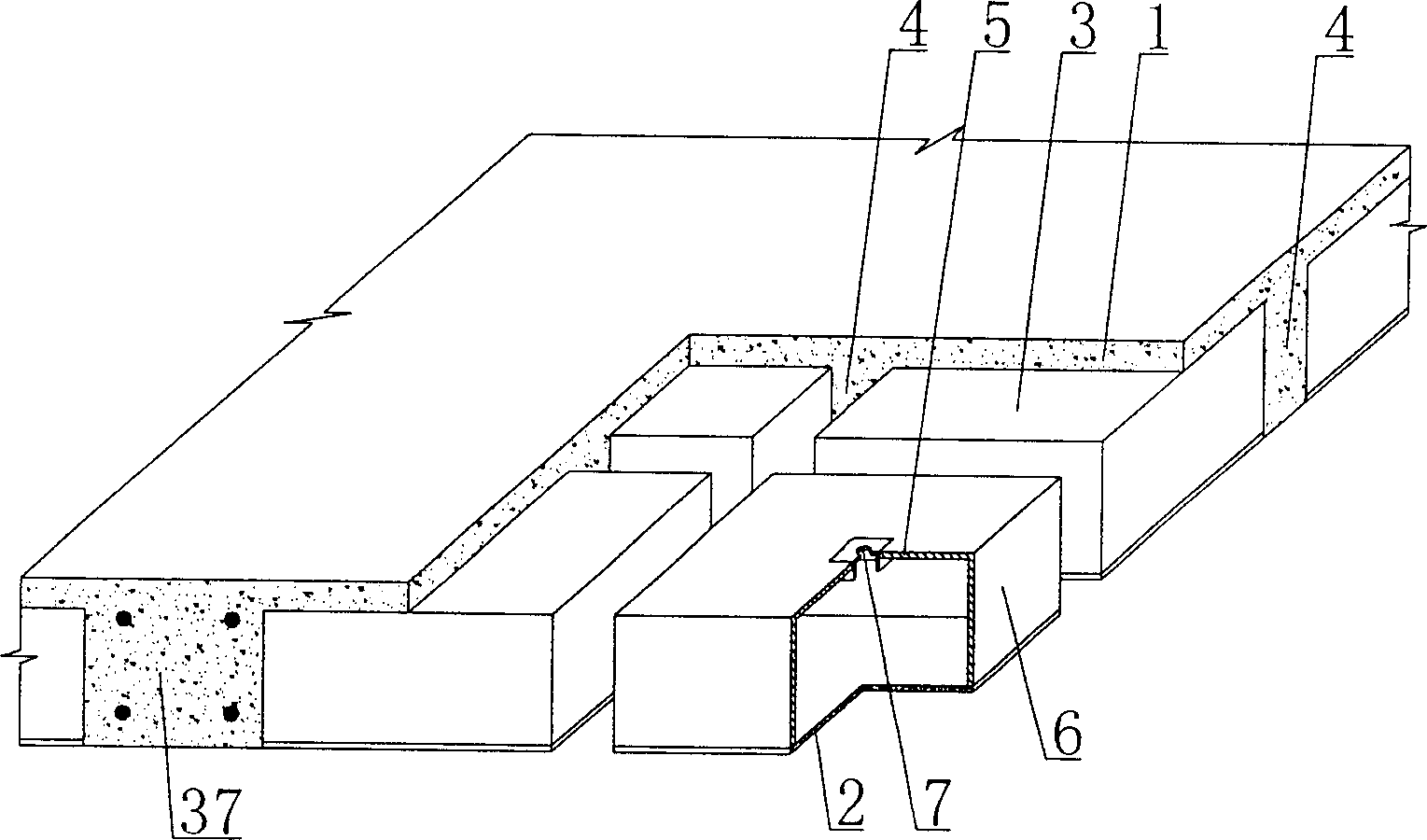

[0069] As shown in the accompanying drawings, the present invention includes reinforced concrete 1, prefabricated thin slabs 2, and formwork members 3, each prefabricated thin slab 2 is arranged horizontally at intervals, formwork members 3 are fixed on the prefabricated thin slabs 2, and reinforced concrete 1 is placed between the formwork members 3 Cast-in-place reinforced concrete ribs 4 are formed between them, the formwork member 3 includes an upper plate 5 and surrounding side walls 6, and the upper plate 5 and surrounding side walls 6 form an open basin-shaped member, which is characterized in that the upper plate 5 Or at least one of the junction box 7 or the line pipe 8 is arranged on at least one of the surrounding side walls 6, and the bottom surface of the prefabricated thin plate 2 is flush with the bottom surface of the cast-in-place concre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com