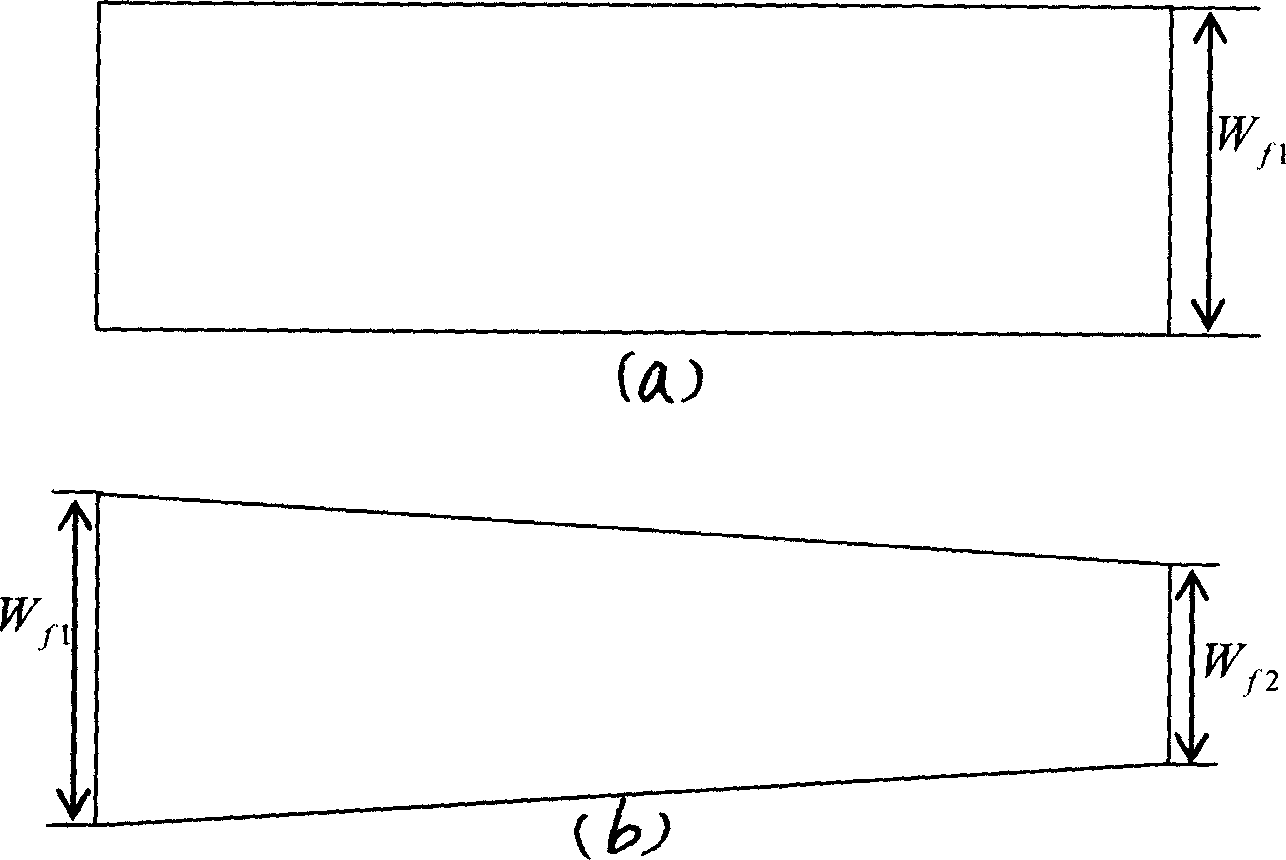

Method for rolling trapezoidal width steel plate

A steel plate and width technology, which is applied in the rolling field of trapezoidal width steel plates, can solve the problems of reducing steel plate utilization efficiency and reducing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

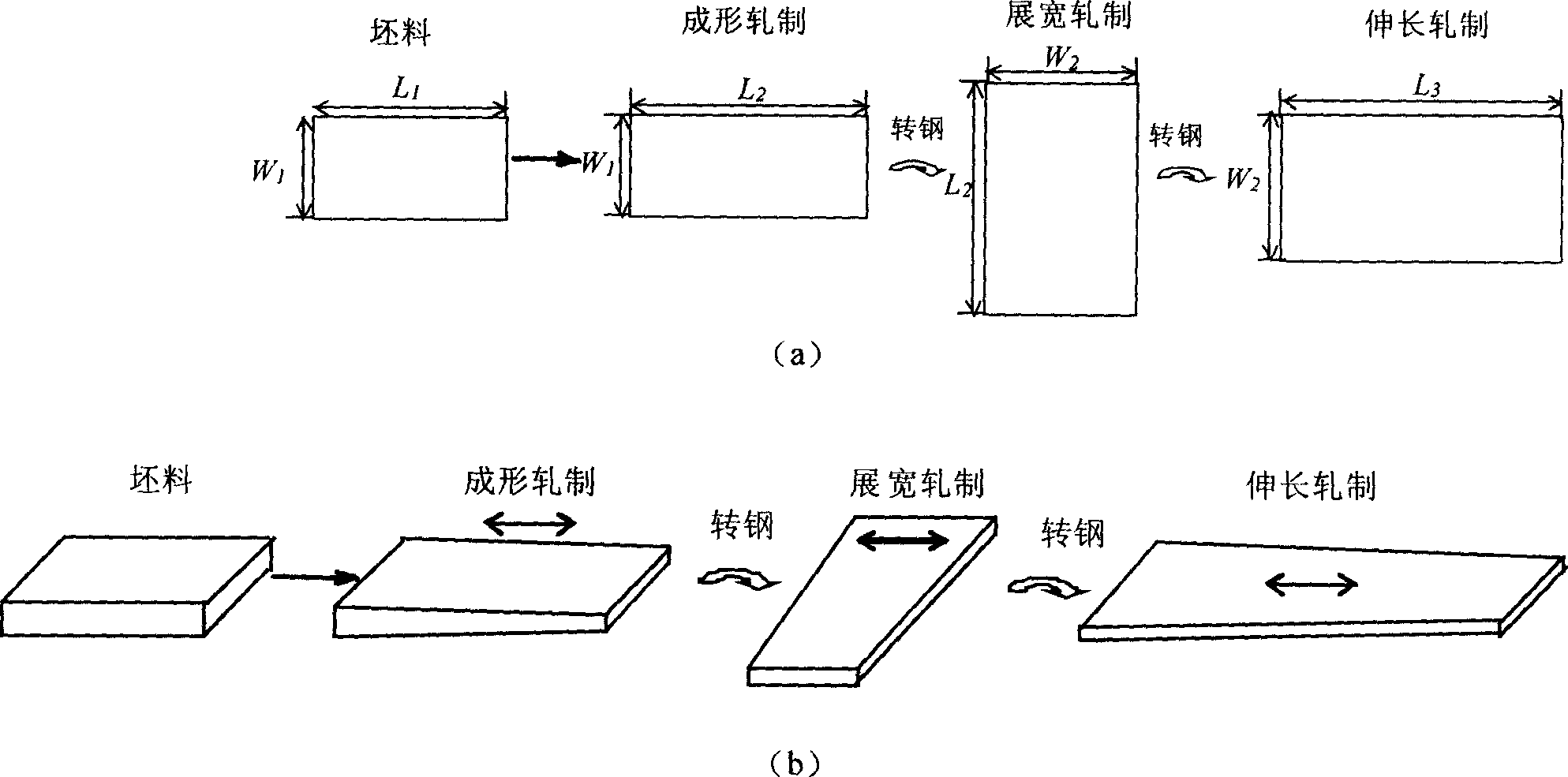

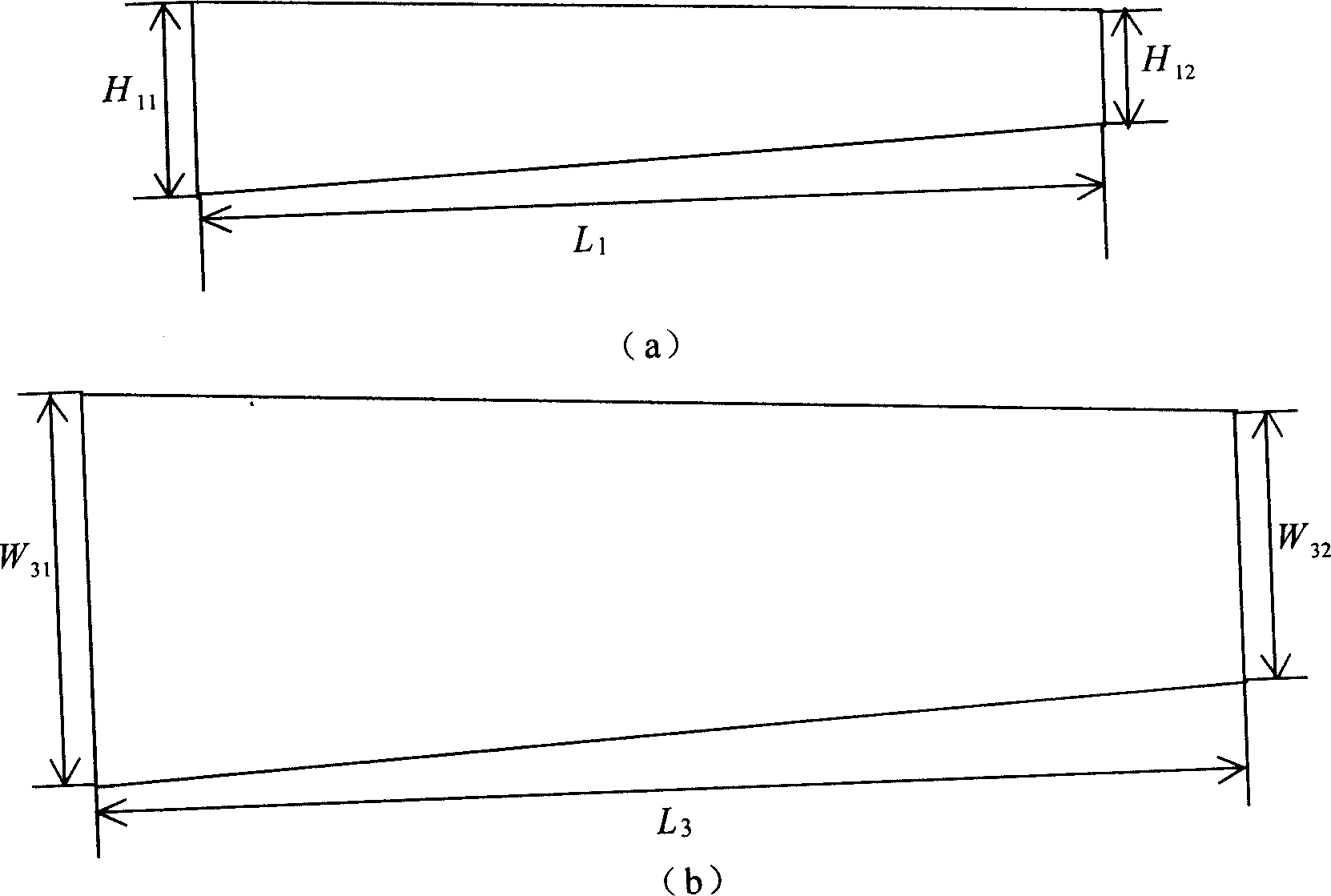

Method used

Image

Examples

Embodiment 1

[0142] Dimensions Thickness 180mm×Width 1400mm×Length 2200 Blank, according to figure 1 It is required to roll a variable width steel plate of 18mm×2200mm-2400mm×10000mm, the longitudinal rigidity of the rolling mill is 6000kN / mm, the zero pressure is 15000kN, the roll radius is 460mm, the maximum allowable rolling force is 35000kN, and the maximum allowable rolling moment is 2750kNm. The maximum rollable width is 2800mm, the maximum opening of the steel transfer table is 4000mm, the maximum compression ratio is 2.5, and the minimum compression ratio is 1.05.

[0143] (1) First, it is necessary to determine the size of the target step thickness in the forming stage

[0144] (1.1) Calculate the thickness and length of the thinner part of the stepped plate in the forming stage

[0145] Corresponding to the maximum rollable width, the minimum value h of the target thickness in the forming stage can be obtained ts1

[0146] h ts ...

Embodiment 2

[0203] Dimensions Thickness 220mm × Width 1600mm × Length 2400mm Blank, according to figure 1 It is required to roll into 25mm×2300mm-2600mm×10000mm variable width steel plates, the longitudinal rigidity of the rolling mill is 8000kN / mm, the zero pressure is 25000kN, the roll radius is 500mm, the maximum allowable rolling force is 55000kN, and the maximum allowable rolling moment is 5000kNm. The maximum rollable width is 3200mm, the maximum opening of the Zhuangang roller table is 4800mm, the maximum compression ratio is 2.5, and the minimum compression ratio is 1.05.

[0204] (1) First, it is necessary to determine the size of the target step thickness in the forming stage

[0205] (1.1) Calculate the thickness and length of the thinner part of the stepped plate in the forming stage

[0206] Corresponding to the maximum rollable width, the minimum value h of the target thickness in the forming stage can be obtained ts1

[0207] h ts ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com