Stepped sulfuric acid treatment and roasting process for decomposing Baotou RE ore concentrate

A technology of rare earth sulfate and rare earth in Baotou, which is applied in the field of non-ferrous metallurgy technology, can solve problems such as low labor intensity, and achieve the effects of solving pollution problems, reducing treatment difficulty and improving resource utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

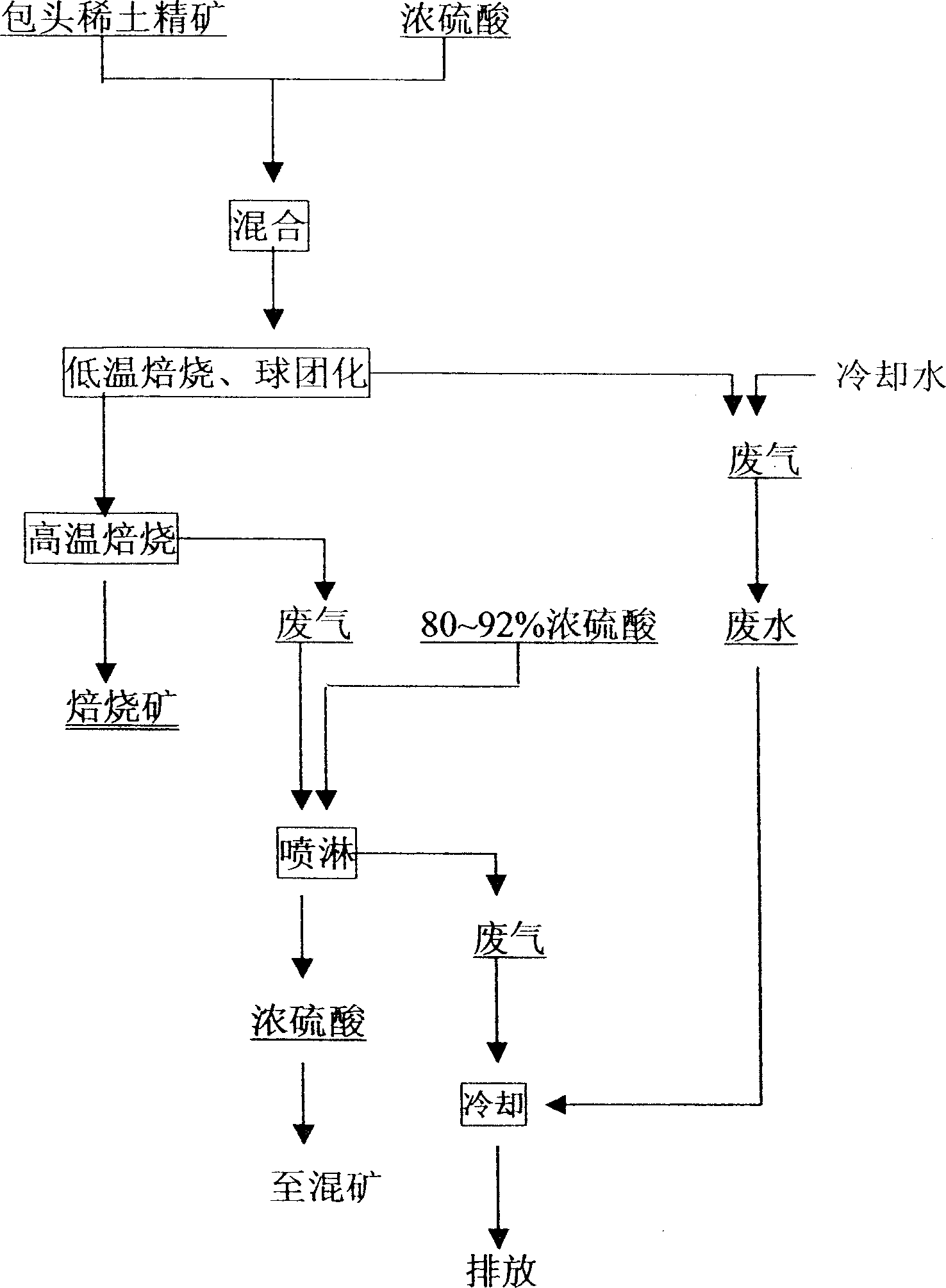

[0027] Add 1.1-1.4 tons of 92% or more concentrated sulfuric acid to 1 ton of 50% rare earth concentrate, fully mix in the mixer, enter the low-temperature kiln, and undergo static batch roasting at 180-300°C for 1.5-3 hours to decompose the concentrate The fluorine-containing mineral part in the waste gas, and the mixed minerals are quickly pelletized, and the first step is roasted. At this time, the main component of the exhaust gas is SiF 4 and HF, using a three-stage falling film absorption tower to spray water to cool and eliminate fluorine in the tail gas; transfer the spheroidized concentrate after the first step of roasting to a high-temperature roasting kiln, and perform dynamic roasting at 700-780°C for 1-3 hours , to complete the decomposition process of all concentrates, and the waste gas produced at this time is SO after decomposition of sulfuric acid 3 , choose 80% ~ 92% concentrated sulfuric acid to recover SO in the secondary packed tower 3 , Sulfuric acid is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com