Coating metal with excellent heat diffusion character

A technology of coating and metal materials, which is applied in the field of coated metals, can solve problems such as inability to exert heat dissipation characteristics, and achieve excellent heat dissipation characteristics, reduced electrical impedance, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

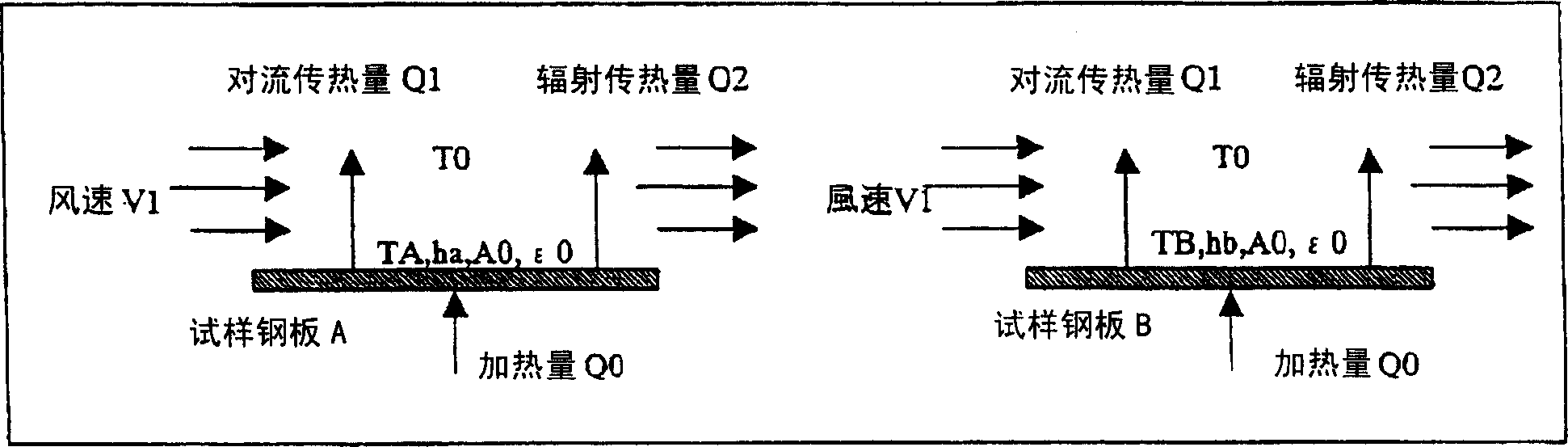

Image

Examples

Embodiment approach

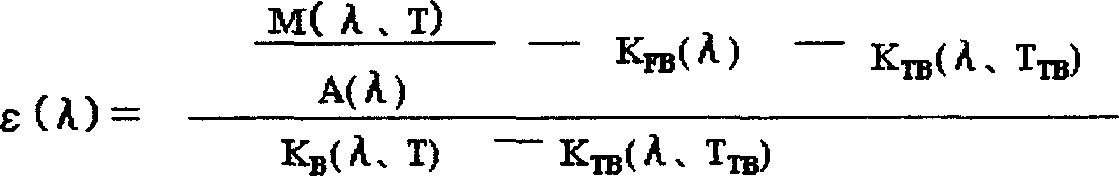

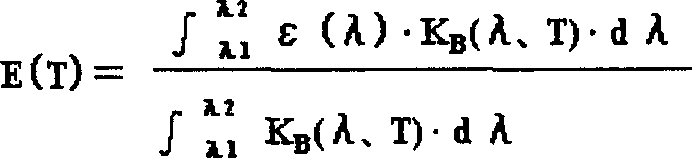

[0064] The integrated infrared emissivity described above is hardly affected by the structure of the outermost coating film containing porous particles, and is almost clearly determined by the structure of the lower coating film containing the radioactive additive. Therefore, in the preferred form of the present invention that combines the undercoat film and the outermost coat film, the integrated emissivity of the undercoat film and the heat dissipation effect produced by the convective heat conduction of the outermost coat film will be brought into play. Thermal properties.

[0065] Carbon black is most preferable as the radioactive additive formulated in the undercoat film. Others can also use oxides, sulfides, carbides, etc. of Co, Ni, Cu, Mn, Ag, Sn, etc., and TiO can also be used. 2 , ceramics, iron oxide, aluminum oxide, barium sulfate, silicon oxide, etc. The preferred compounding amount of these radioactive additives is 1% by mass or more, more preferably 2% by mass...

Embodiment

[0085] Chromate-treated electro-galvanized steel sheet (thickness: 0.8mm, Cr deposition amount: 20mg / m 3 ) is used as an original plate, and the coating compounded with the additives shown in the following Table 1 is applied on one side (polyester-based resin is used as the base resin, and melamine resin is used as the cross-linking agent), and then baked and dried to form Undercoat film.

[0086] Next, a polyester-based resin prepared with fine particles shown in Table 1 was coated thereon, and then baked and dried to form an outermost coating film. In this polyester-based resin, a large amount of porous silica (Mizusawa Chemical Co., Ltd. (trade name "Mizukasil P-707" manufactured by Japan Chemical Industry Co., Ltd.), or a large amount of zeolite (trade name "Zeostar KA-100P" manufactured by Nihon Kagaku Co., Ltd.) with surface openings and pores with a diameter of about 0.3 nm, and dried in the coating film The ratio becomes 10% by mass.

[0087] For each of the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com