Functional biomembrane carrier, its preparation method and use

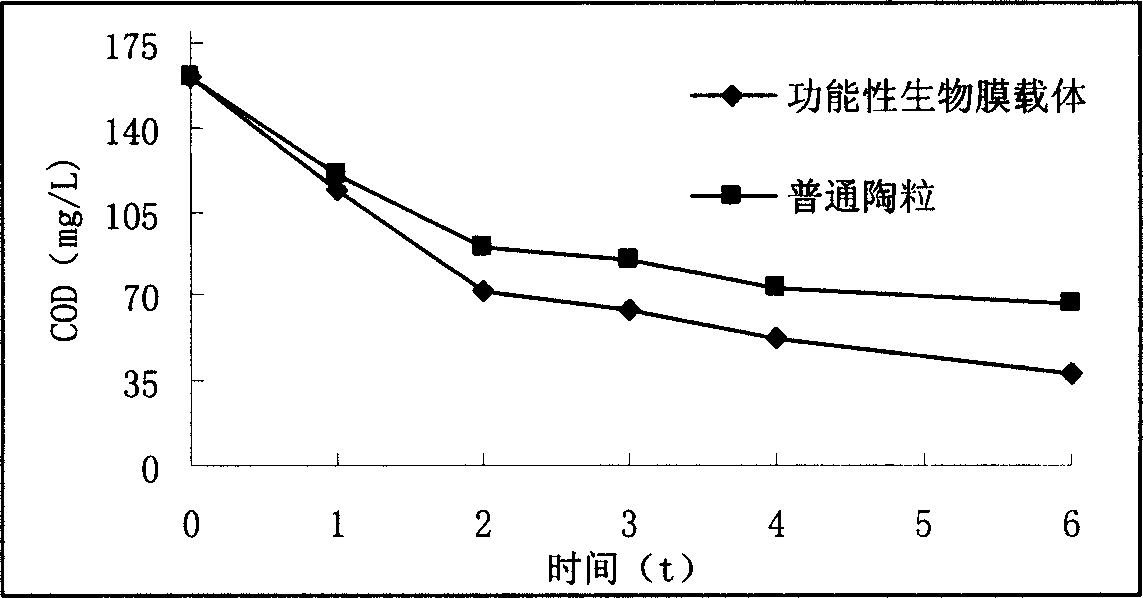

A biofilm carrier and functional technology, applied in the direction of sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of slow film formation and inability to actively provide a good environment for microbial growth, and achieve The effect of promoting the growth of microorganisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The functional biofilm carrier of the present invention has the following ingredients by weight: 1% of tourmaline, 15% of hydrotalcite, 20% of montmorillonite, 54% of diatomite and 10% of aluminum oxide.

[0023] The preparation method of the functional biofilm carrier is as follows: mix hydrotalcite, montmorillonite, diatomite, and alumina materials according to the above-mentioned proportion, grind them to 200 mesh, and then add tourmaline powder with a particle size of 200 mesh according to the ratio , add water, stir and mix thoroughly, put it into a molding machine for extrusion molding, and granulate in a disc granulator to obtain spherical granule raw meal. Spherical granular raw meal is first dried naturally, then moved into a horse boiling furnace and heated to 120°C for 1 hour, and then heated to 800°C for 3 hours to obtain a functional biofilm carrier.

Embodiment 2

[0025] The functional biofilm carrier of the present invention has the following ingredient ratios: 5% of tourmaline, 10% of hydrotalcite, 20% of montmorillonite, 55% of diatomite and 10% of aluminum oxide.

[0026]The production process of the functional biofilm carrier is as follows: mix hydrotalcite, montmorillonite, diatomite, and alumina materials according to the above-mentioned ratio, grind them to 300 mesh by a grinder, and then add them according to the ratio. Purpose Tourmaline micropowder is mixed with water, mixed thoroughly, put into a molding machine, extruded, granulated, and granulated raw meal is obtained. The granular raw materials are first dried naturally, then moved into a horse boiling furnace and heated to 100°C for 1.5 hours; then heated to a roasting temperature of 820°C for 5 hours to obtain a functional biofilm carrier.

Embodiment 3

[0028] The functional biofilm carrier of the present invention has the following ingredient ratios: 10% of tourmaline, 5% of hydrotalcite, 15% of montmorillonite, 65% of diatomite and 5% of aluminum oxide.

[0029] The production process of the functional biofilm carrier is as follows: mix hydrotalcite, montmorillonite, diatomite, and alumina according to the above-mentioned ingredient ratio, grind them to 300 mesh, and then add tourmaline powder with a particle size of 2000 mesh according to the ratio , add water, stir and mix thoroughly, extrude, and granulate to obtain granule raw meal. Spherical granular raw material is first dried naturally, then moved into a horse boiling furnace and heated to 110°C, and kept at a constant temperature for 2 hours; then heated to a roasting temperature of 850°C, and fired for 3.5 hours to obtain a functional biofilm carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com