Semiconductor device and method for making the same

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problems of MCM reliability or yield deterioration, and prevent reliability or yield reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

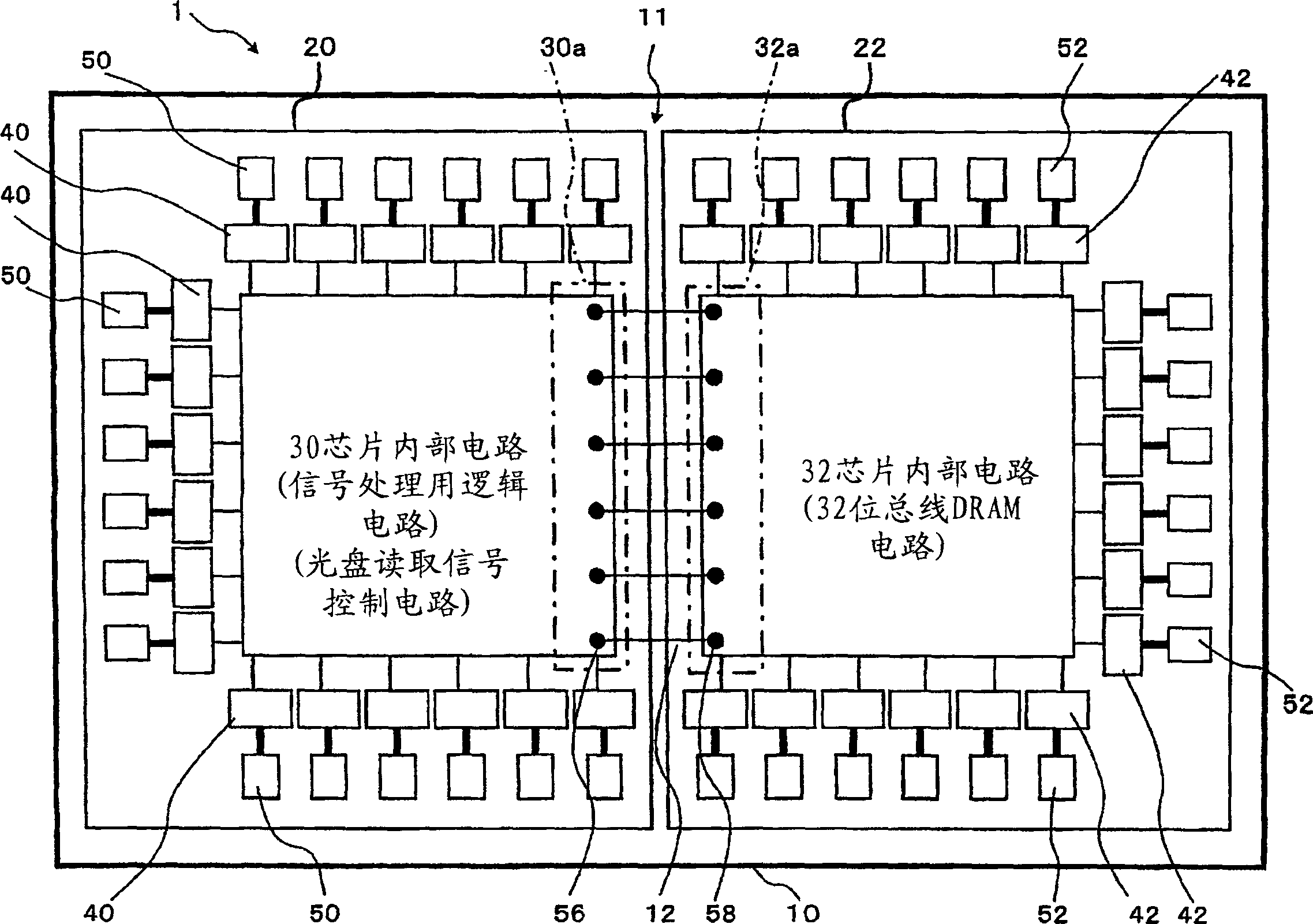

[0037] figure 1 It is a plan view showing the first embodiment of the semiconductor device to which the present invention is applied. The semiconductor device 1 shown in this figure mounts a plurality of substantially square ( figure 1 A so-called MCM type semiconductor device constituted by two) semiconductor chips 20 and 22 is shown in FIG.

[0038] Here, the first semiconductor chip 20 is, for example, a semiconductor chip for logic in which a logic circuit for signal processing is formed as the chip internal circuit 30 . On the other hand, the second semiconductor chip 22 is, for example, a semiconductor chip for a memory in which a DRAM (Dynamic RAM: Dynamic Random Access Memory) circuit forming a 32-bit bus is formed as the chip internal circuit 32 . Furthermore, the structure of the internal circuits 30 and 32 of the semiconductor chips 20 and 22 is not limited thereto.

[0039] For example, the semiconductor chips 20 and 22 are die-bonded on the support substrate 10...

no. 2 Embodiment approach

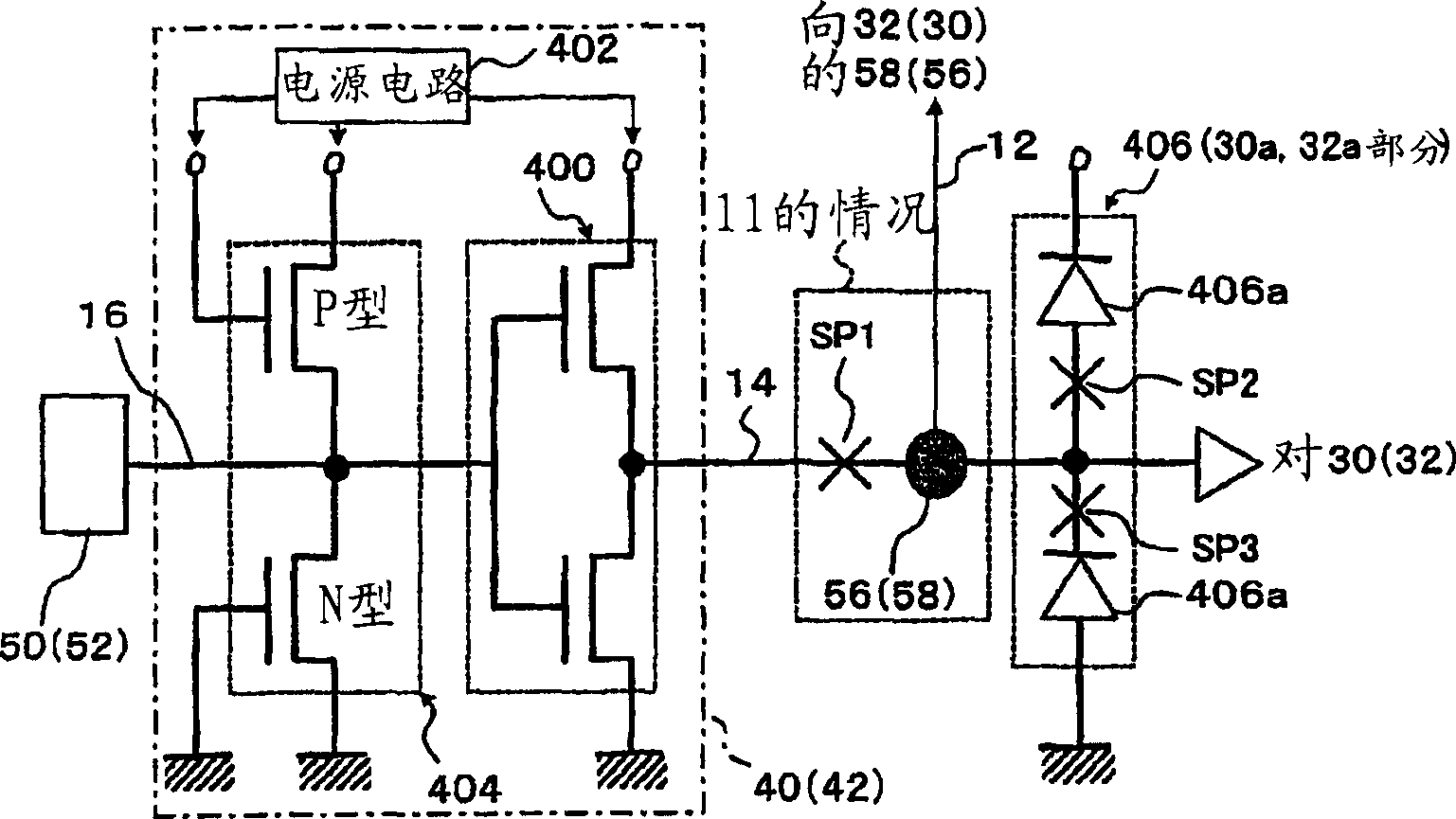

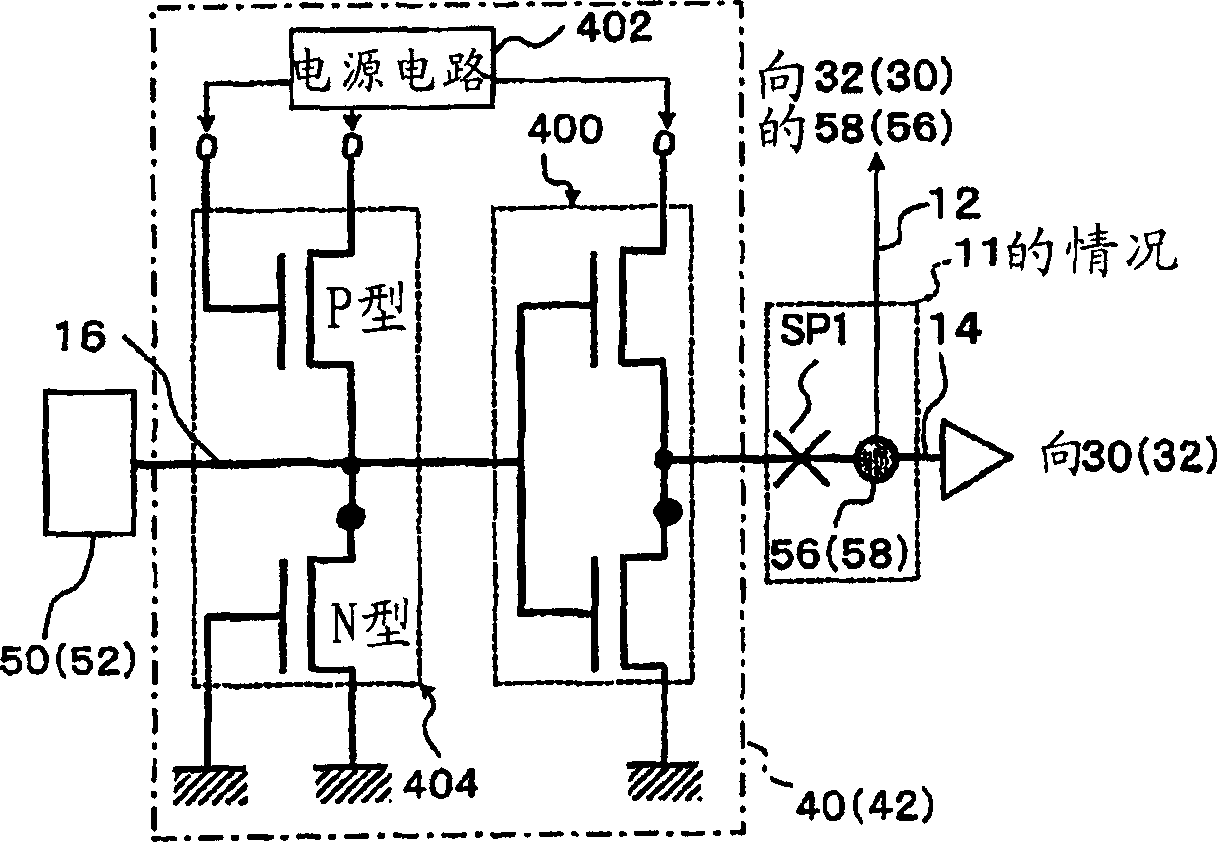

[0095] Figure 5A to Figure 5B It is a figure explaining the 2nd Embodiment of the semiconductor device to which this invention was applied. This figure is for the second embodiment Figure 3A to Figure 3C corresponding figure. The semiconductor device 1 of the second embodiment is characterized in that the protection circuit 406 can be disconnected from the signal line directly connected between the internal circuits 30 and 32 of the chip by using a switching circuit capable of turning on and off the input and output. to form. The semiconductor chips 20 and 22 differ only in that they have switching circuits, and the plan view of the semiconductor device 1 is basically the same as that of figure 1 Same as shown.

[0096] On the other hand, as the circuit structure of the inter-chip connection portion 11, for example, as shown in FIG. There is a switch circuit 408 between the circuits 406 that can switch between input and output. The switching circuit 408 is provided as ...

no. 3 Embodiment approach

[0101] Figure 6A to Figure 6B and Figure 7A to Figure 7B It is a figure explaining the 3rd embodiment of the semiconductor device to which this invention was applied. here, Figure 6A It is a plan view showing the third embodiment, and FIG. 6B is a sectional view taken along line A-A of the plan view. Figure 7A to Figure 7B shown to represent Figure 6A Details of the A-A line section of the floor plan.

[0102] like Figure 6A to Figure 6B and Figure 7A As shown, the semiconductor device 1 of the third embodiment is characterized in that the semiconductor chips 20 and 22 are face-down mounted using bumps. The rest of the configuration is substantially the same as that of the first or second embodiment, and a protection circuit 406 is provided on the signal line directly connected to the chip internal circuits 30 and 32 of the inter-chip connection portion 11 . The protection circuit 406 is the same as the first or second embodiment, and its purpose is to protect th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com