Method for direct production of core in narrow groove and blind hole of wax mould

A technology of wax mold and blind hole, which is applied in the direction of core, casting mold, casting mold composition, etc., can solve complex casting process and other problems, and achieve the effects of broad prospects, low production cost and shortened production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

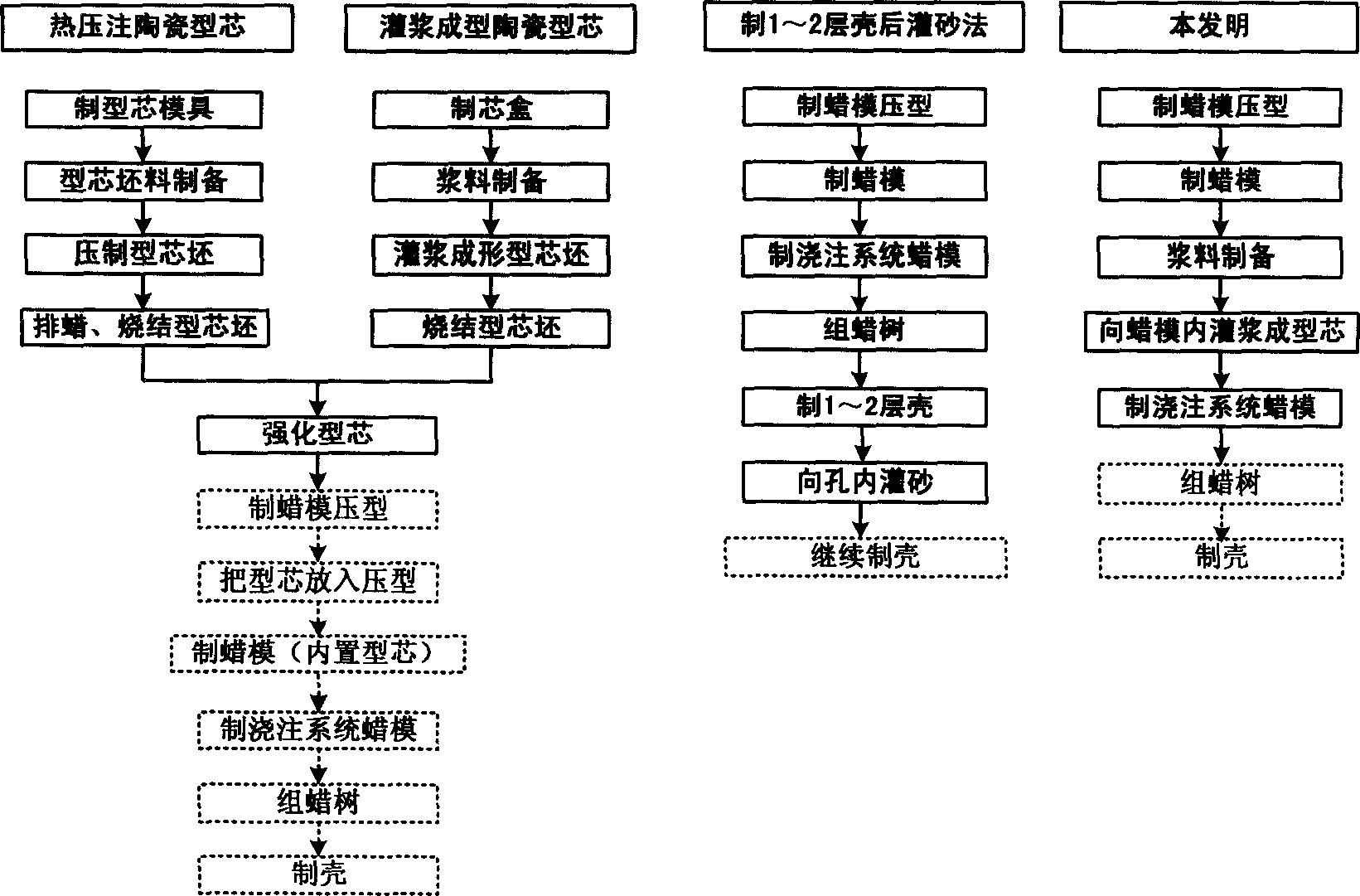

Method used

Image

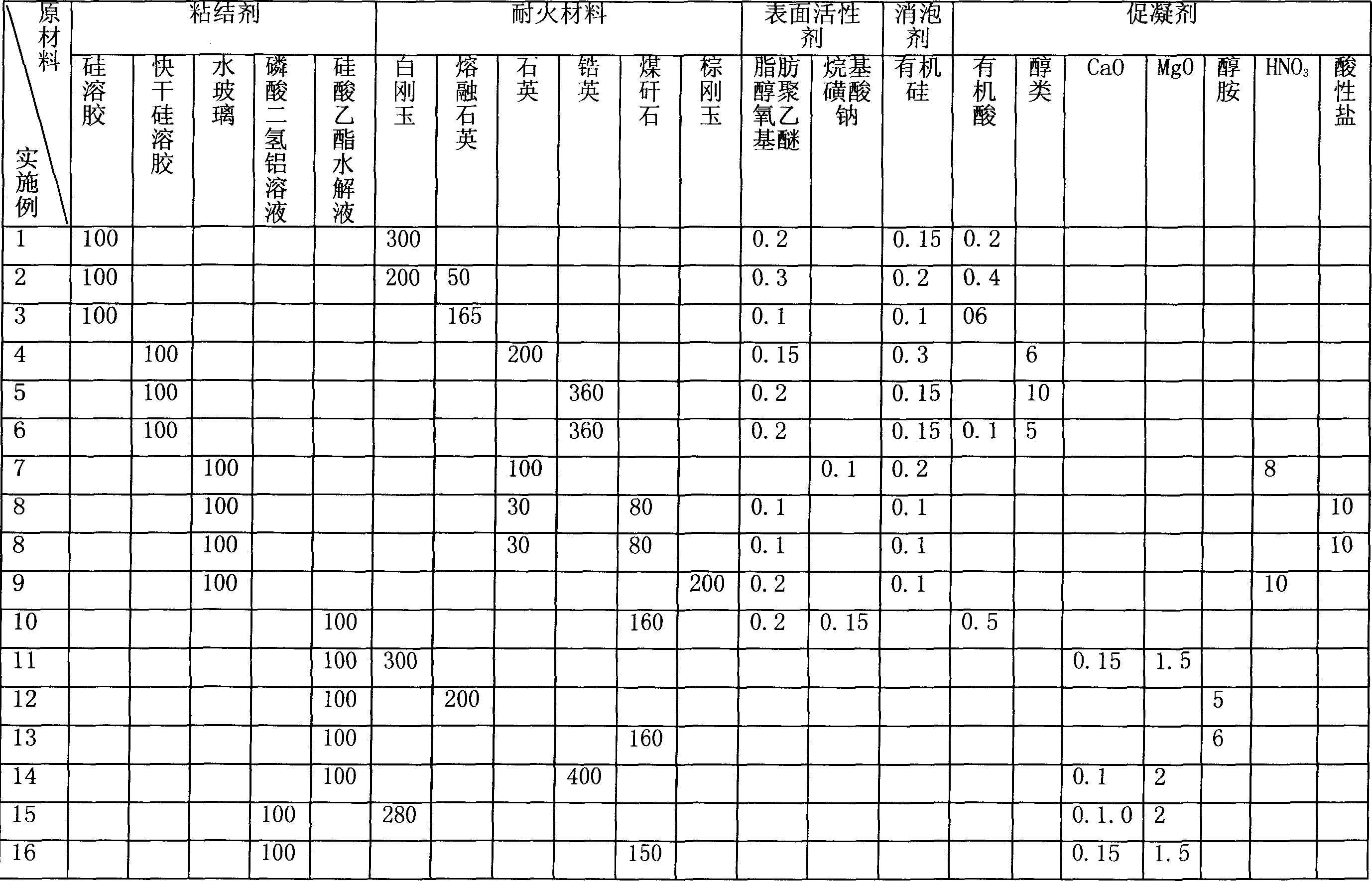

Examples

Embodiment 1

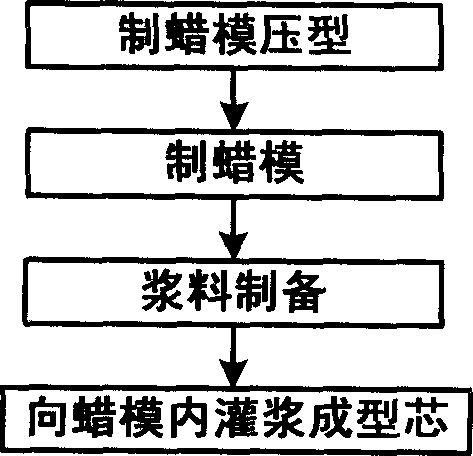

[0106] A method for directly manufacturing cores in narrow grooves and blind holes of wax patterns, the method comprises the following steps:

[0107] (1) wax mold pressure type

[0108] According to casting requirements, design and manufacture wax mold pressing;

[0109] (2) Wax mold making

[0110] The wax material is pressed into the wax mold described in step (1) to form a wax mold with deep grooves and blind holes;

[0111] (3) Slurry preparation

[0112] According to the ratio of each mass unit, add the raw materials and mix them in the order of binder, surfactant, refractory material, defoamer, and coagulant to prepare slurry; the addition amount is: binder silica sol 100g, refractory material fused silica 200g, coagulant organic acid 0.1g, surfactant fatty alcohol polyoxyethyl ether (JFC) 0.3g, defoamer silicone defoamer 0.2g;

[0113] (4) Grouting into the wax mold

[0114] Pour the slurry prepared in step (3) into the deep groove and blind hole of the wax mold p...

Embodiment 2

[0116] A method for directly manufacturing cores in narrow grooves and blind holes of wax patterns, the method comprises the following steps:

[0117] (1) wax mold pressure type

[0118] According to casting requirements, design and manufacture wax mold pressing;

[0119] (2) Wax mold making

[0120] The wax material is pressed into the wax mold described in step (1) to form a wax mold with deep grooves and blind holes;

[0121] (3) Slurry preparation

[0122] According to the ratio of each mass unit, add the raw materials and mix them in the order of binder, surfactant, refractory material, defoamer, and coagulant to prepare slurry; the addition amount is: binder water glass 100g, refractory material quartz 50g , coal gangue 70g, coagulant acid 0.1g, surfactant fatty alcohol polyoxyethyl ether (JFC) 0.2g, defoamer silicone defoamer 0.3g

[0123] (4) Grouting into the wax mold

[0124] Pour the slurry prepared in step (3) into the deep groove and blind hole of the wax mol...

Embodiment 3

[0126] A method for directly manufacturing cores in narrow grooves and blind holes of wax patterns, the method comprises the following steps:

[0127] (1) wax mold pressure type

[0128] According to casting requirements, design and manufacture wax mold pressing;

[0129] (2) Wax mold making

[0130] The wax material is pressed into the wax mold described in step (1) to form a wax mold with deep grooves and blind holes;

[0131] (3) Slurry preparation

[0132] According to the mass ratio, add the raw materials in order of binder, refractory material and coagulant to prepare slurry; the addition amount is: binder ethyl silicate hydrolyzate 100g, refractory corundum 300g, coagulant alcohol Amine 2g;

[0133] (4) Grouting into the wax mold to make the core

[0134] Pour the slurry prepared in step (3) into the deep groove and blind hole of the wax mold prepared in step (2); after the slurry in the wax mold is solidified, the narrow groove and blind hole of the wax mold are d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com