Organic electroluminescence device and method of producing the same

An electroluminescent device, organic light-emitting layer technology, applied in the direction of electroluminescent light source, electric light source, lighting device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

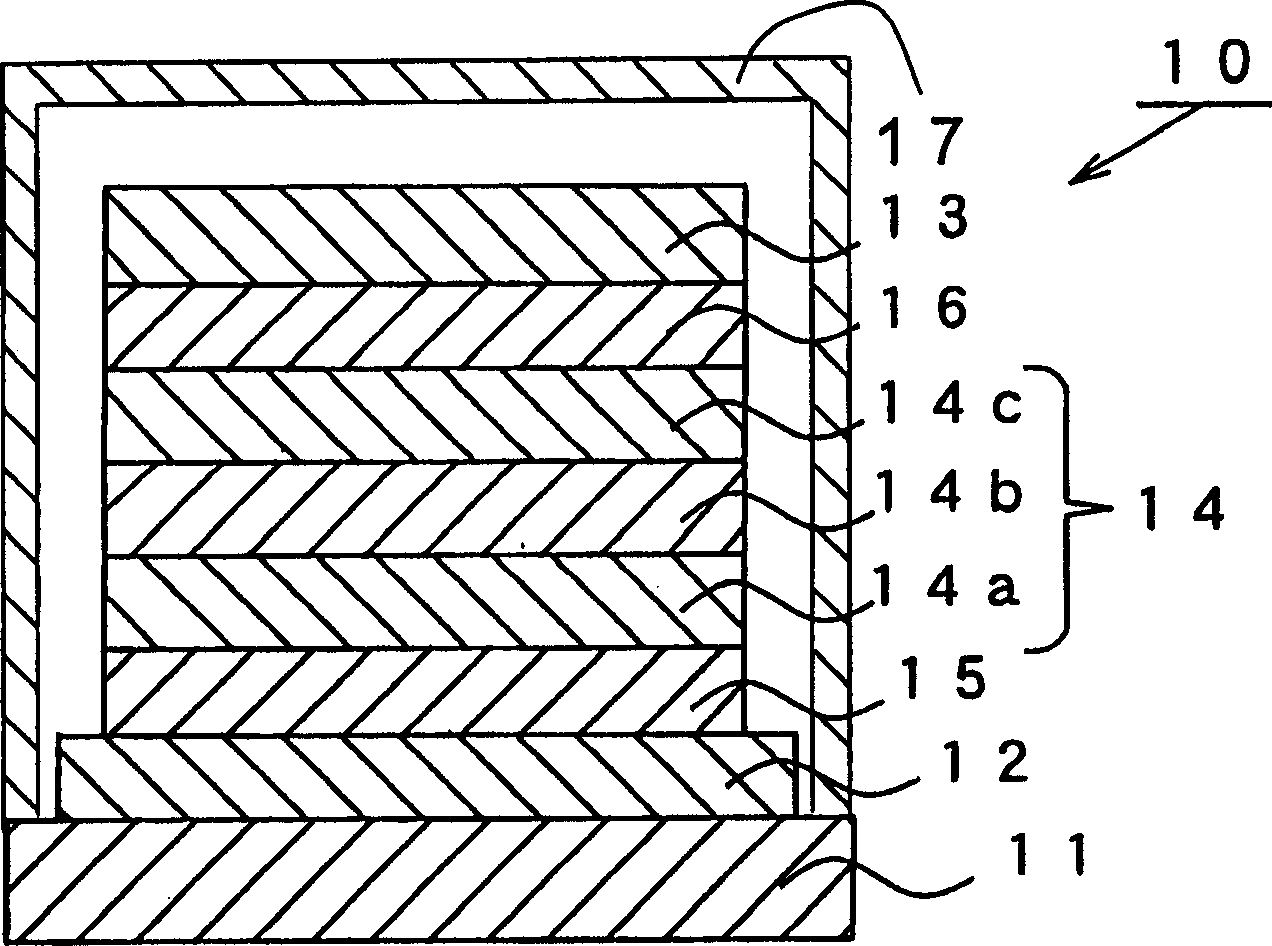

[0041] An anode layer 12 formed of an ITO layer having a thickness of 150 nm was formed on one surface of a transparent glass substrate 11, and the substrate / anode layer structure was subjected to substrate cleaning in which alkali cleaning and pure water cleaning were performed successively, and after being After drying, ultraviolet ozone cleaning is performed.

[0042] Then, the anode layer 12 was treated with plasma of an oxygen-argon mixed gas having an argon content of 10 vol % for two minutes at a pressure of 2 Pa and a radio frequency power of 200 W. Before the plasma treatment, the work function of the surface of the anode layer 12 was 4.6 eV, and after the plasma treatment, its work function was about 5.7 eV.

[0043] After the anode layer 12 is subjected to plasma treatment, by utilizing a vapor deposition device such as a graphite crucible at a deposition rate of 0.1 nm / s and about 5.0×10 -5 A vacuum degree of Pa deposited a TPTE layer of an amine-based low-molecul...

Embodiment 2-9

[0054]For the production of the organic EL devices of Examples 2-9, except that the argon content in the oxygen-argon mixed gas used for plasma treatment is 30vol%, 43vol%, 49vol%, 55vol%, 59vol%, 69vol%, 82vol% % and 89 vol%, the others are the same as those of the organic EL device 10 of Example 1. The work function of the surface of the anode layer 12 after plasma treatment is 5.7-5.9 eV. As in the case of the power coefficient of the organic EL device 10 of Example 1, the power coefficients of the organic EL devices 10 of Examples 2-9 were measured before and after the heating test and the light irradiation test. Table 1 also shows the results of the retention ratios of the power coefficients of the organic EL devices of Examples 2-9.

[0055] heating test

light test

Example

Argon content (vol%)

Power Coefficient Retention

Power Coefficient Retention

1

10

100%

70%

2

30

101%

80%

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com