Thin film transistor, method for producing thin film transistor and pixel structure

A technology of thin film transistors and manufacturing methods, applied in the fields of thin film transistors and their manufacturing, and pixel structure manufacturing, can solve problems affecting the electrical performance of the channel layer 140, and achieve the effect of improving the manufacturing pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

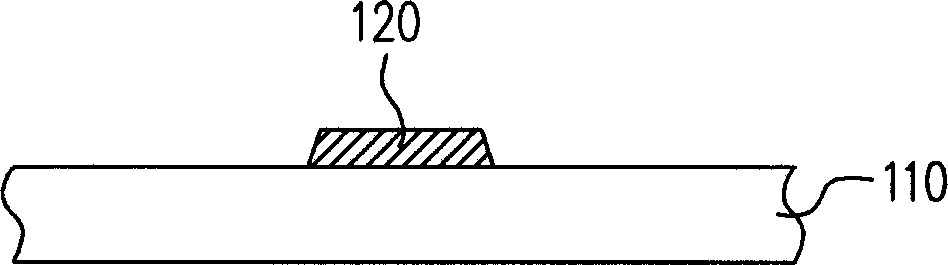

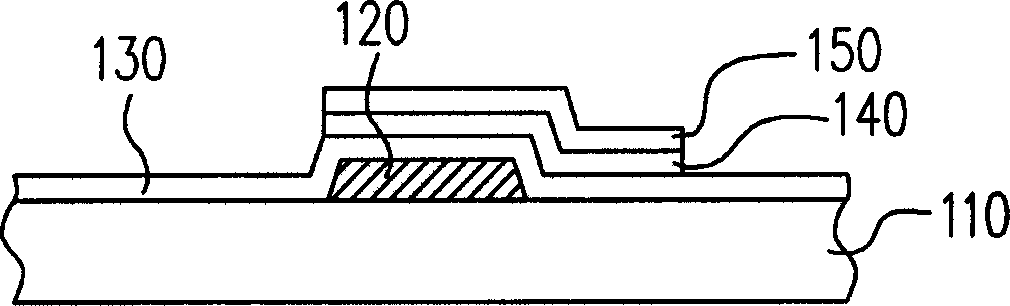

[0027] Figure 2A-2E It is a schematic cross-sectional view of a manufacturing process of a thin film transistor in a preferred embodiment of the present invention. First, please refer to Figure 2A , forming a gate 220 on the substrate 210 . In one embodiment, the method of forming the gate 220 is, for example, depositing a conductive layer (not shown in the figure) on the substrate 210 first, and then using a photomask (not shown in the figure) to cooperate with the photolithography process to The conductive layer is patterned to form a gate 220 on the substrate 210 . The photolithography steps mentioned above are common semiconductor manufacturing processes, so the details of these steps are well known to those skilled in the art and will not be repeated here.

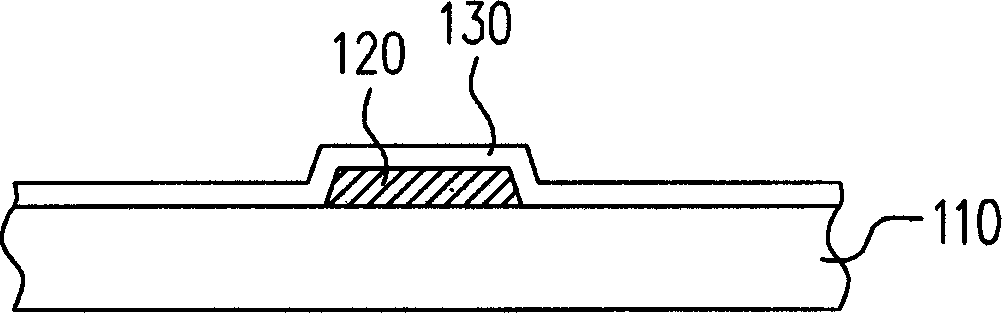

[0028] Next, please refer to Figure 2B , a gate insulating layer 230 is formed on the substrate 210 to cover the gate 220 . The method of forming the gate insulating layer 230 is, for example, physical vapor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com