Method for producing glass fiber reinforced plastic composite material plate spring

A composite material plate and manufacturing method technology, applied in the field of leaf springs, can solve the problems of reducing vehicle load capacity, large vehicle impact force, and high production cost, and achieve the effects of long-term shape stability, large elastic strain, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

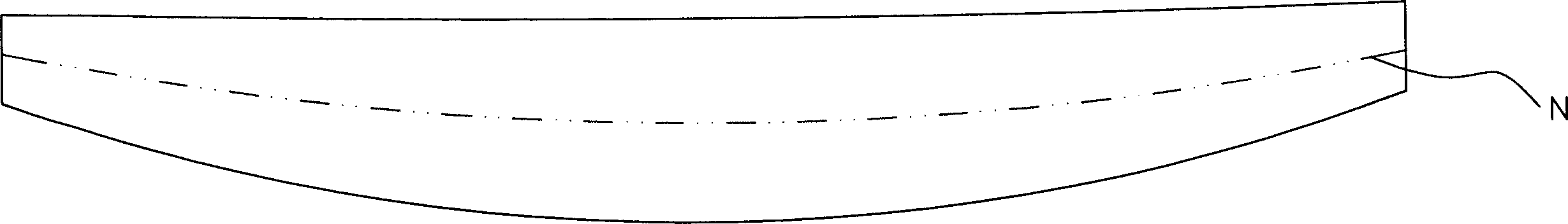

[0026] Such as figure 1 , 2 As shown, the manufacturing method of the FRP composite material leaf spring of the present invention, it first impregnates the roving or gray cloth made of glass fiber material, and then lays it in the epoxy resin matrix in a multi-layer superimposed manner, Then place it in a mold and press it into a rectangular leaf spring; the lower surface of the leaf spring is a paraboloid that is thick in the middle and gradually thins toward the two ends along the length direction; the thickness at both ends is smaller than the maximum thickness in the middle.

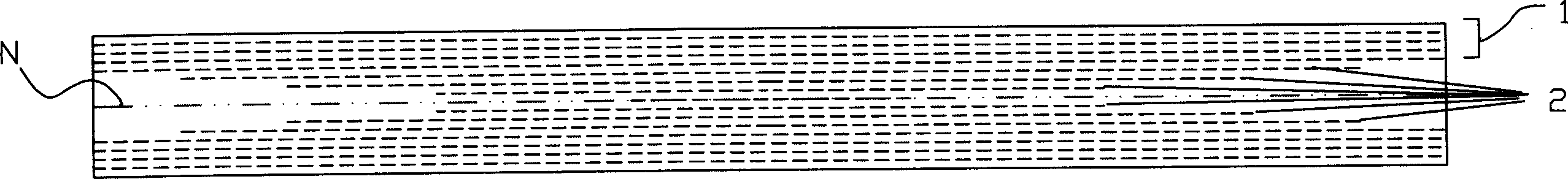

[0027] The roving or gray cloth made of the multi-layer glass fiber material can be superimposed and laid in the following manner:

[0028] Based on the central plane N of the thickness of the leaf spring, the fiber material layer near the upper and lower surfaces of the leaf spring is an outer layer 1 that extends continuously to the entire length direction of the leaf spring; the fiber material la...

Embodiment 2

[0030] Such as figure 1 , 3 As shown, the manufacturing method of the FRP composite material leaf spring of the present invention, it first impregnates the roving or gray cloth made of glass fiber material, and then lays it in the epoxy resin matrix in a multi-layer superimposed manner, Then place it in a mold and press it into a rectangular leaf spring; the lower surface of the leaf spring is a paraboloid that is thick in the middle and gradually thins toward both ends along the length direction; the thickness of both ends is smaller than the maximum thickness in the middle.

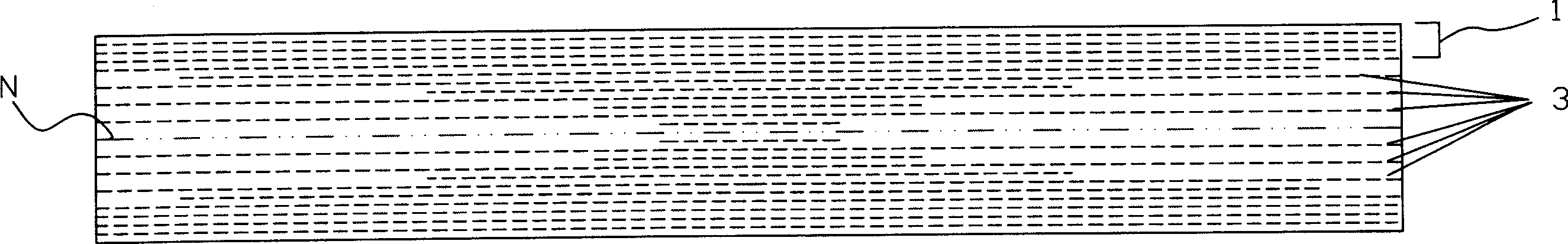

[0031] The roving or gray cloth made of the multi-layer glass fiber material can be superimposed and laid in the following manner:

[0032] Based on the central plane N of the thickness of the leaf spring, the fiber material layer near the upper and lower surfaces of the leaf spring is an outer layer 1 that extends continuously to the entire length direction of the leaf spring; the fiber material layer...

Embodiment 3

[0034] Such as Figure 4 Shown, in embodiment 1 or 2, described outer layer 1 also can be laid like this:

[0035] The outer layer 1 away from the surface of the leaf spring is disconnected near the end of the leaf spring, and the truncation point 4 moves successively from the upper layer front of the outer layer 1 to the lower layer rear of the outer layer 1; the truncated outer layer 1 can It is a superposition of single layer, double layer or multiple layers.

[0036] Such as Figure 5 As shown, the outer layer 1 can also be laid in the following way: the outer layer 1 is laid with a stepped layer 5 passing through the entire truncation point 4 through the position of the truncation point 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com