Method and device for current limitation with an automatic current limiter

A current-limiting device and current-limiting technology, applied in relays, emergency protection devices, circuit-breakers with excessive current, etc. using electrodynamic effects, which can solve problems such as large current limiters, contamination of liquid metal, and wear and tear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

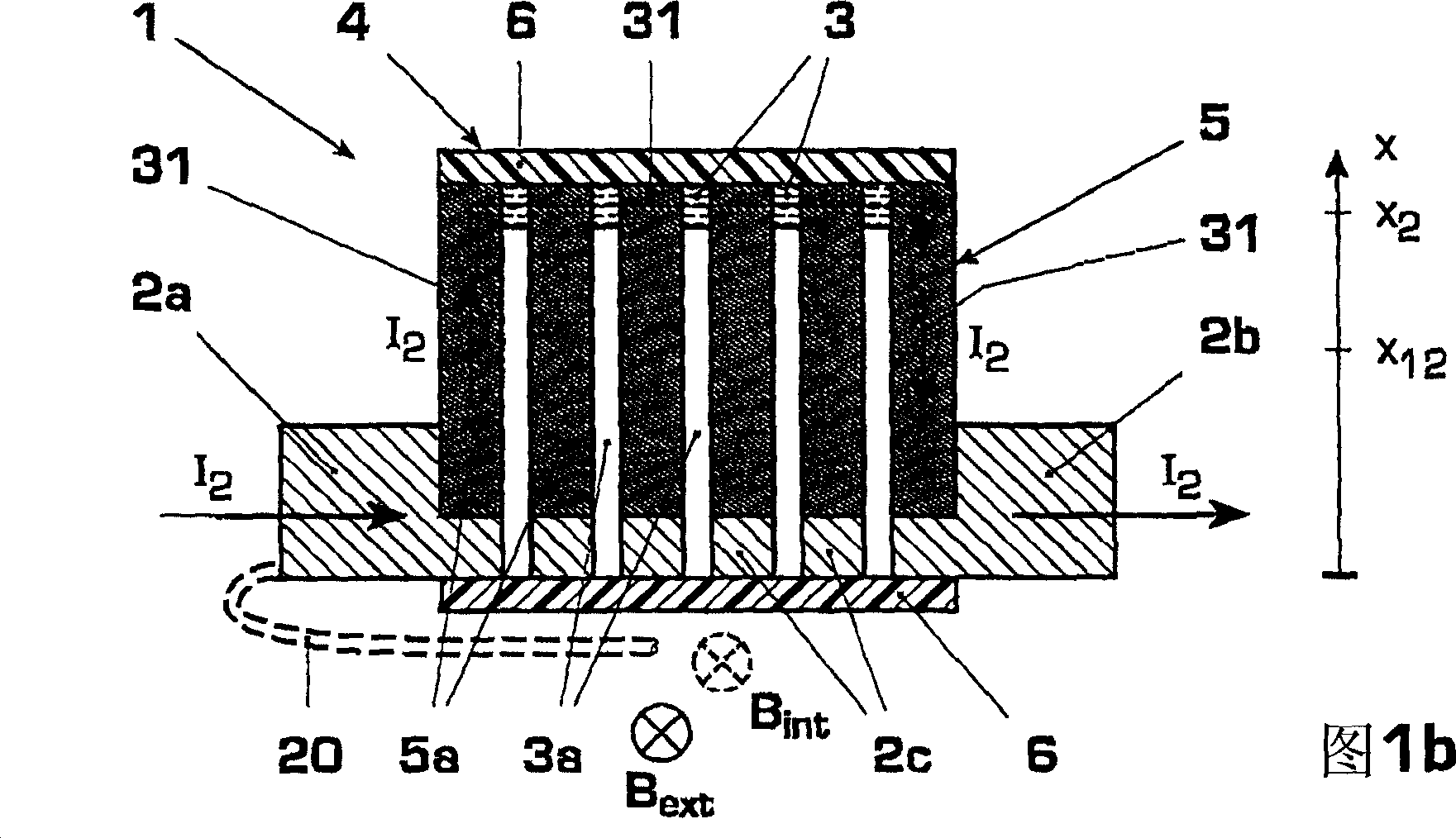

[0025] Figures 1a, 1b show an embodiment of a flow restrictor 1 of the liquid metal type. The current limiter 1 comprises solid metal electrodes 2 a , 2 b and an intermediate electrode 2 c for a current source 20 and a container 4 for liquid metal 3 . The container 4 has a bottom 6 and a cover 6 of electrically insulating material, between which an electrical impedance device 5 with at least one channel 3a for the liquid metal 3 is arranged. Above the liquid metal body, for example, a protective gas, an insulating liquid (with a spare volume not shown in the figure) or a vacuum can be provided.

[0026] According to the invention, the liquid metal 3, or in general a movable electrode 3, is connected to the overcurrent electrode I to be limited. 2 Automatic electromagnetic interaction is driven. In the case of liquid metal 3, the liquid metal remains in a liquid aggregate state and is arbitrarily at different positions x by forced movement 1 、x 12 or x 2 to move between. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com