Apparatus and method for long spiral-drilling enlarging-base agitation and reaming-in-hole concrete filling to form pile

A technology of long helical drilling and long helix, which is applied in the direction of drilling equipment and methods, sheet pile walls, drilling equipment, etc., and can solve the problems of low construction cost, accident-prone, high construction cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

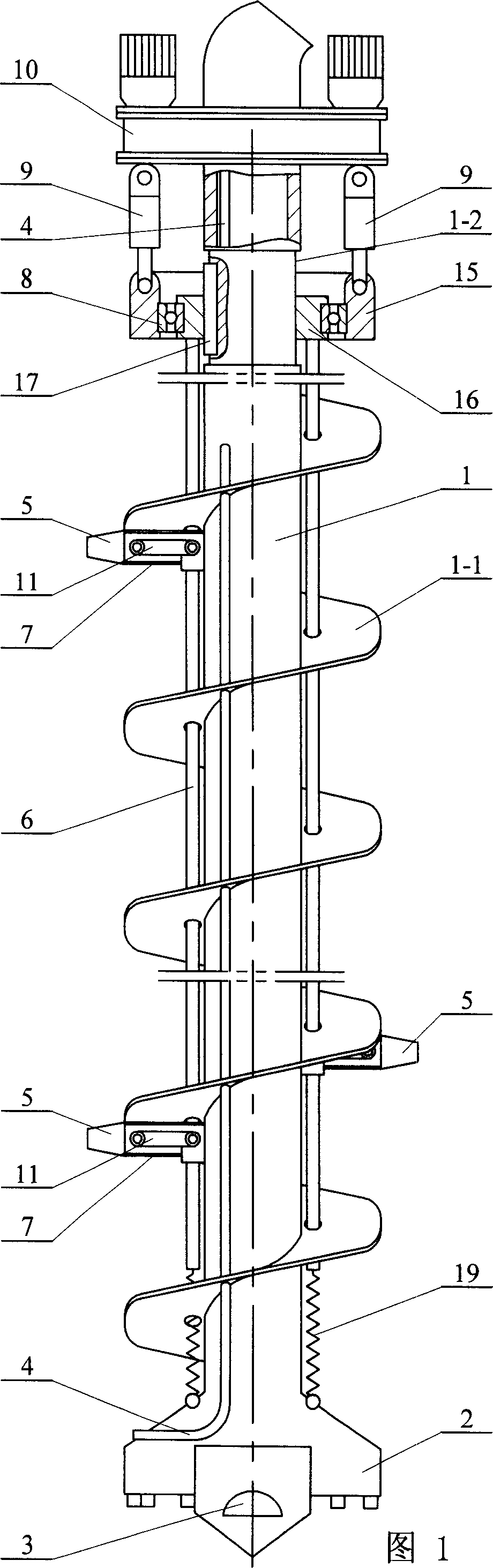

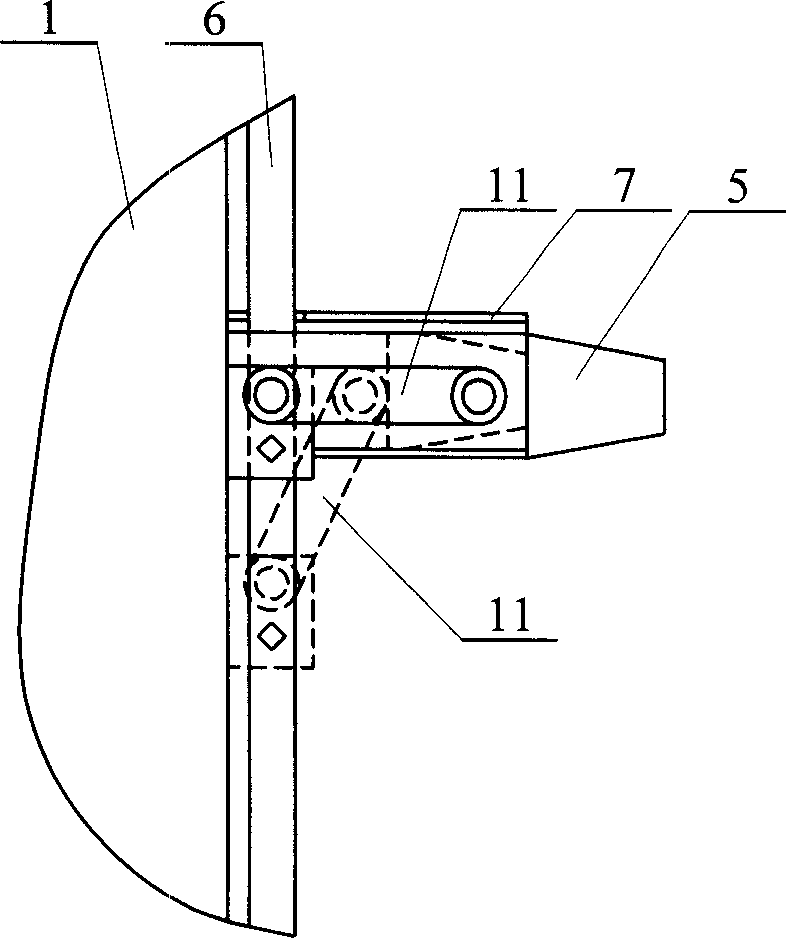

[0007] Specific embodiment one: present embodiment is made up of following steps: one, with long auger drill pile hole to specified depth; ground. 2. Gradually expand several reamers arranged on the long helical drilling tool along the height direction until the reamers are respectively inserted into the hole wall of the pile hole, and at the same time, the grouting pipe arranged on the long auger The grout is injected at the bottom of the hole, during which the long auger drill is always rotating; the grout is mainly composed of cement and water, the weight ratio of water and ash is generally about 0.6, and the pressure of grouting is about 2Mpa. 3. The long helical drilling tool is gradually lifted up to complete the expansion and stirring of the bottom of the pile hole by the reaming cutter located at the lower end of the long auger drilling tool, and the partial expansion of the hole wall of the pile hole by other reaming cutters; 4. Stop grouting and retract the reaming c...

specific Embodiment approach 2

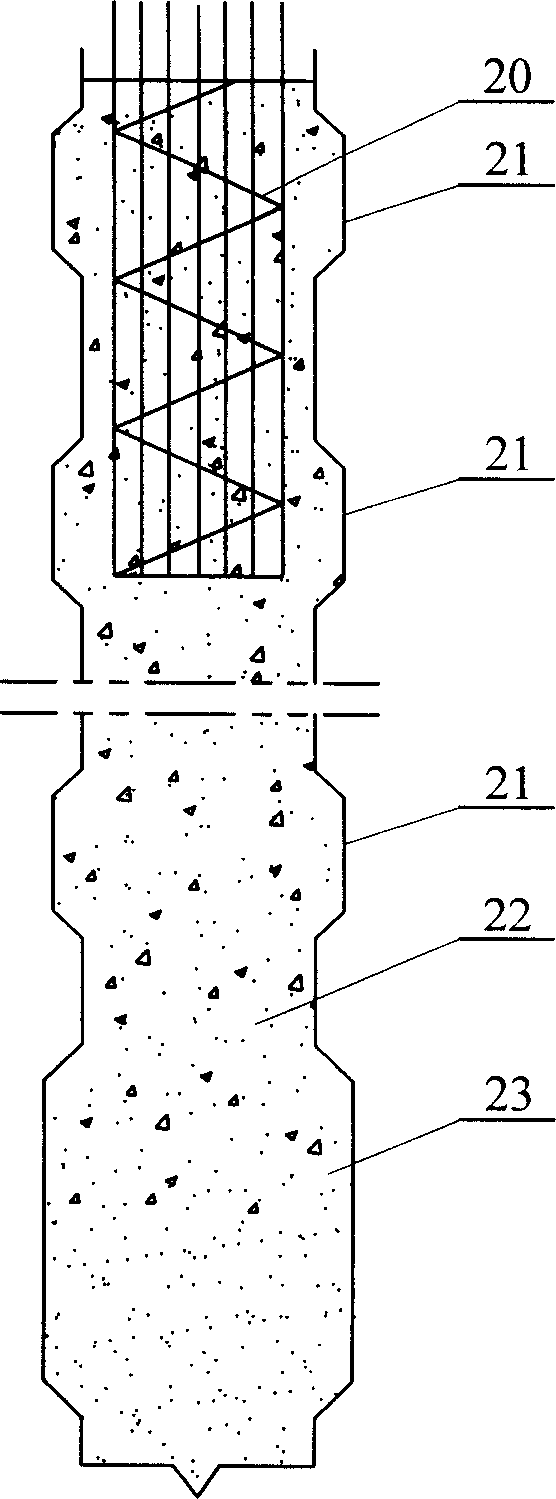

[0008] Specific embodiment two: this embodiment is made up of the following steps: one, drill the pile hole with the long helical drilling tool to the specified depth; The reamers are respectively inserted into the hole wall of the pile hole, and at the same time, the grout is injected into the bottom of the pile hole from the grouting pipe arranged on the long auger. During this period, the long auger always rotates; 3. The long auger gradually lifts up Complete the bottom expansion and stirring of the bottom of the pile hole by the reamer located at the lower end of the long auger and the local expansion of the wall of the pile hole by other reamers; 4. Stop grouting and retract the reamer; 5. Through the long auger Concrete is poured into the bottom of the pile hole in the internal cavity; six, a long auger is proposed, and the reinforcement cage 20 is inserted into the pile hole manually or by a vibrating device, and then the concrete is solidified into a pile.

specific Embodiment approach 3

[0009] Specific embodiment three: the difference between this embodiment and embodiment two is: in step one, the long auger drill is spraying water or mud to the pile hole through the grouting pipe while drilling, and the mud is mixed evenly by water and clay. become. With this arrangement, the stone chips on the hole wall can be washed down and returned to the ground, and at the same time, the surface of the hole wall is more stable and not easy to collapse. Other steps are the same as the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com