Construction method for on-site segmental pouring type concrete gallery and water storage pond

A construction method and pouring technology, applied in water conservancy projects, artificial islands, waterway systems, etc., can solve problems such as high construction costs and inconvenient construction of concrete containers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A construction method for segmental pouring concrete pipe gallery on site, comprising the following steps:

[0040] S1: Excavating a trench, and constructing a concrete floor 10 at the bottom of the trench;

[0041] S2: Construct the pipe gallery unit of the first segment, specifically including the following steps:

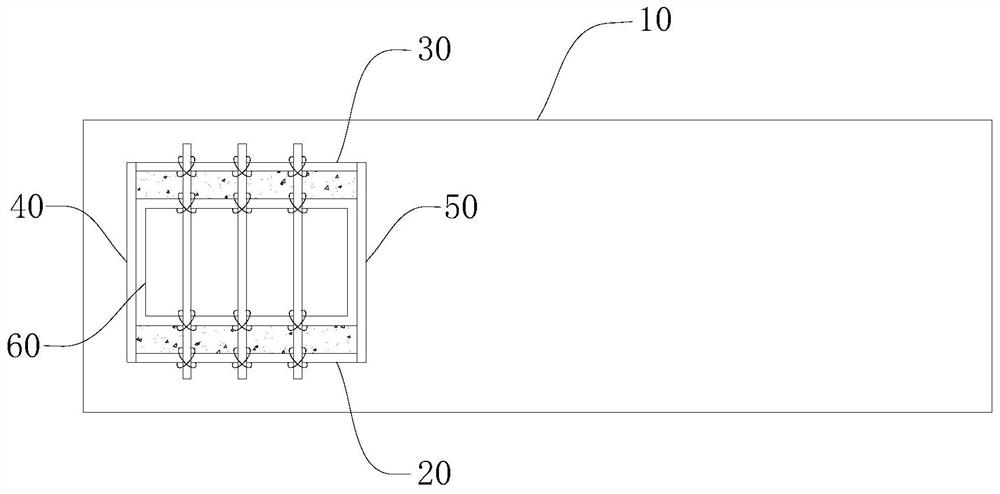

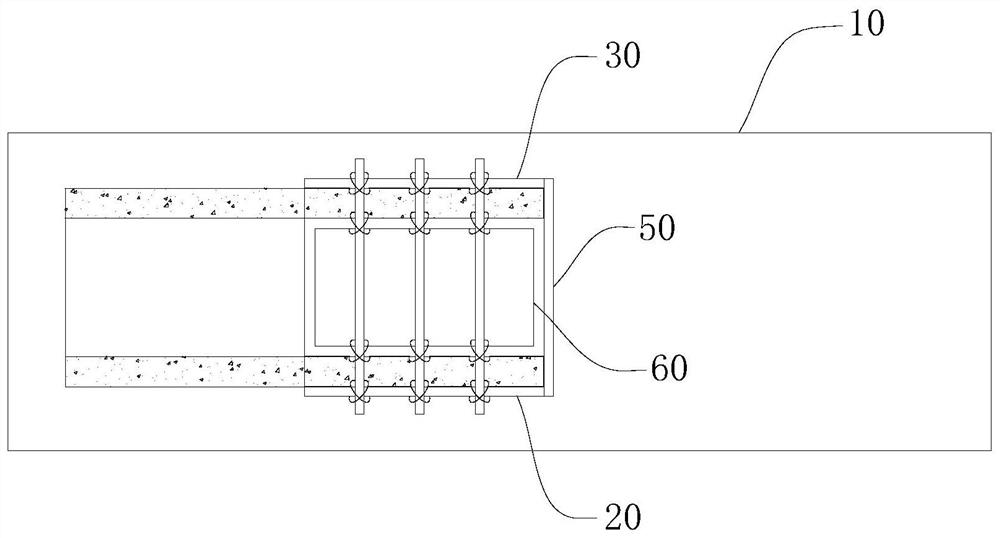

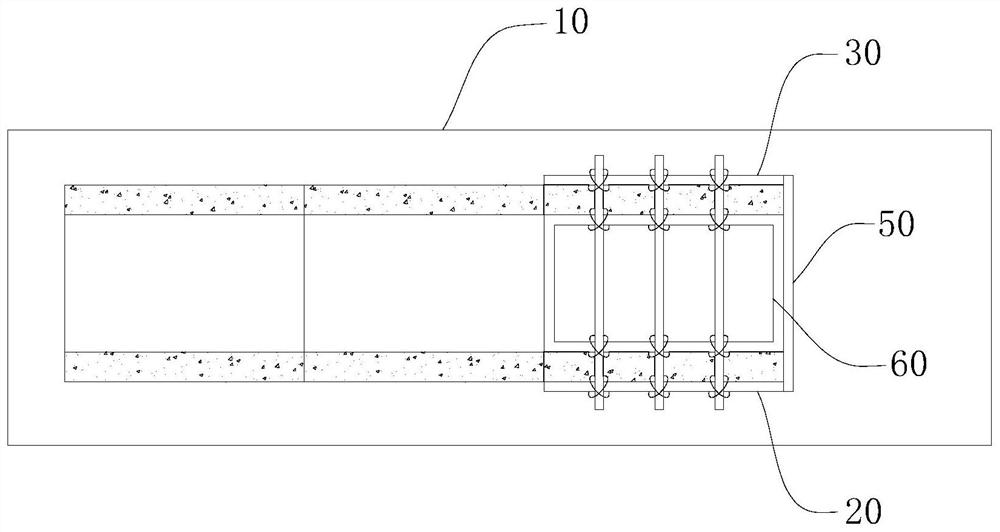

[0042] S21: install the left mold 20 and the right mold 30 and the front mold 40 and the rear mold 50 on the bottom plate 10 through bolts, the left mold 20 and the right mold 30 are arranged in parallel, and the front mold 40 and the rear mold 50 are respectively located The two ends of the left side mold 20 and the right side mold 30, and the plate surface of the front end mold 40 and the rear end mold 50 are in contact with the end faces of the left side mold 20 and the right side mold 30 to form an outer mold;

[0043] S22: Set the prefabricated reinforcement mesh inside the outer form near the base plate 10, the left formwork 20 and the right formwor...

Embodiment 2

[0054] A construction method for a field segmental pouring concrete sewage treatment tank, comprising the following steps:

[0055] S1: Concrete base plate 10 is constructed at the pre-construction position;

[0056] S2: constructing the sewage treatment tank unit of the first segment, specifically including the following steps:

[0057] S21: install the left mold 20 and the right mold 30 and the front mold 40 and the rear mold 50 on the bottom plate 10 through bolts, the left mold 20 and the right mold 30 are arranged in parallel, and the front mold 40 and the rear mold 50 are respectively located The two ends of the left side mold 20 and the right side mold 30, and the plate surface of the front end mold 40 and the rear end mold 50 are in contact with the end faces of the left side mold 20 and the right side mold 30 to form an outer mold;

[0058] S22: Set the prefabricated steel mesh inside the outer mold close to the bottom plate 10, the left mold 20, the right mold 30, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com