Energy-saving iron and steel industry energy efficiency tracking and controlling management apparatus and energy-saving controlling method thereof

A technology of iron and steel industry, tracking control, applied in the direction of comprehensive factory control, comprehensive factory control, energy industry, etc., can solve the problems of energy consumption on demand, optimal control, single centralized control, etc., to achieve high technical content and good energy saving effect , the effect of convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

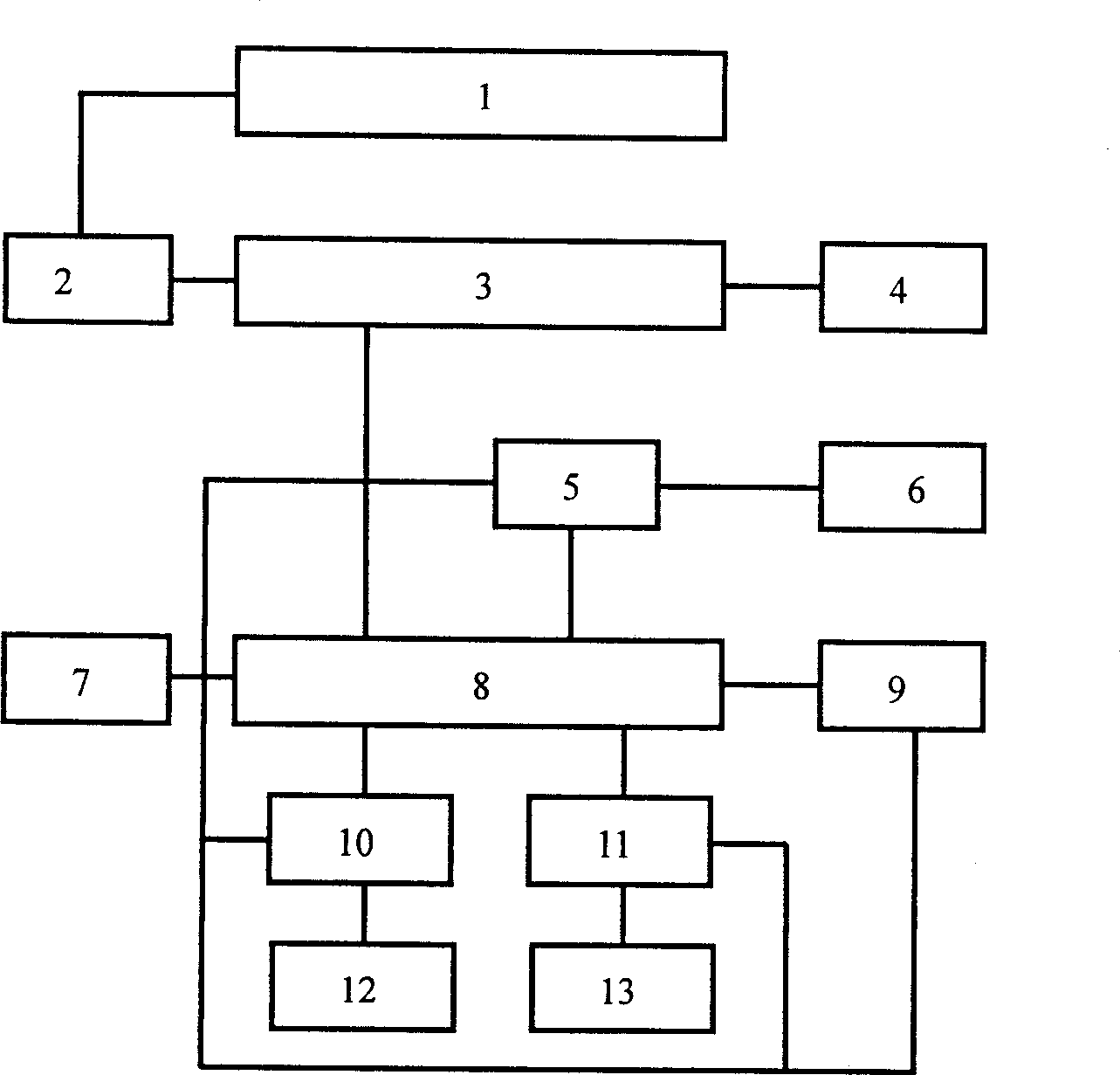

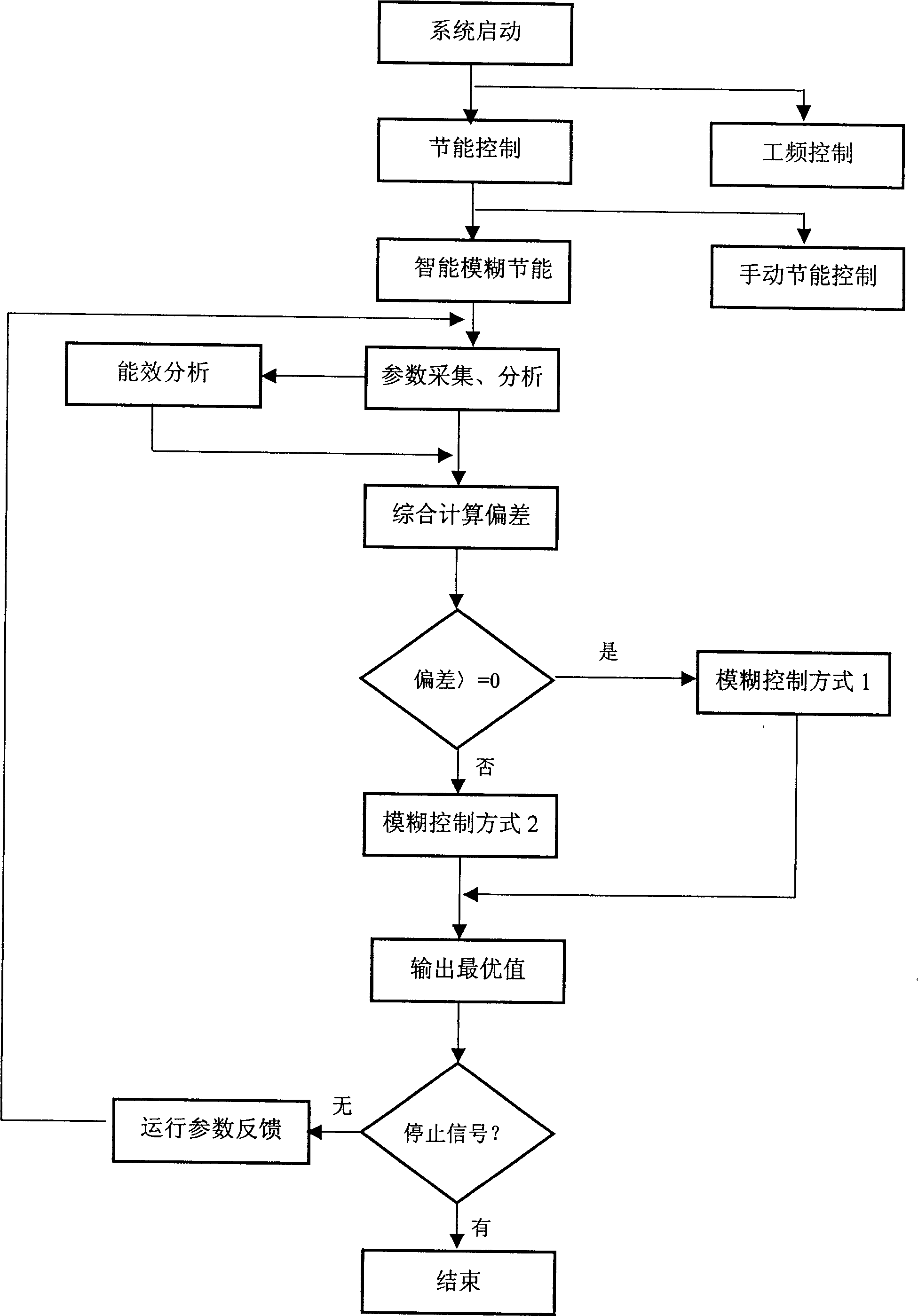

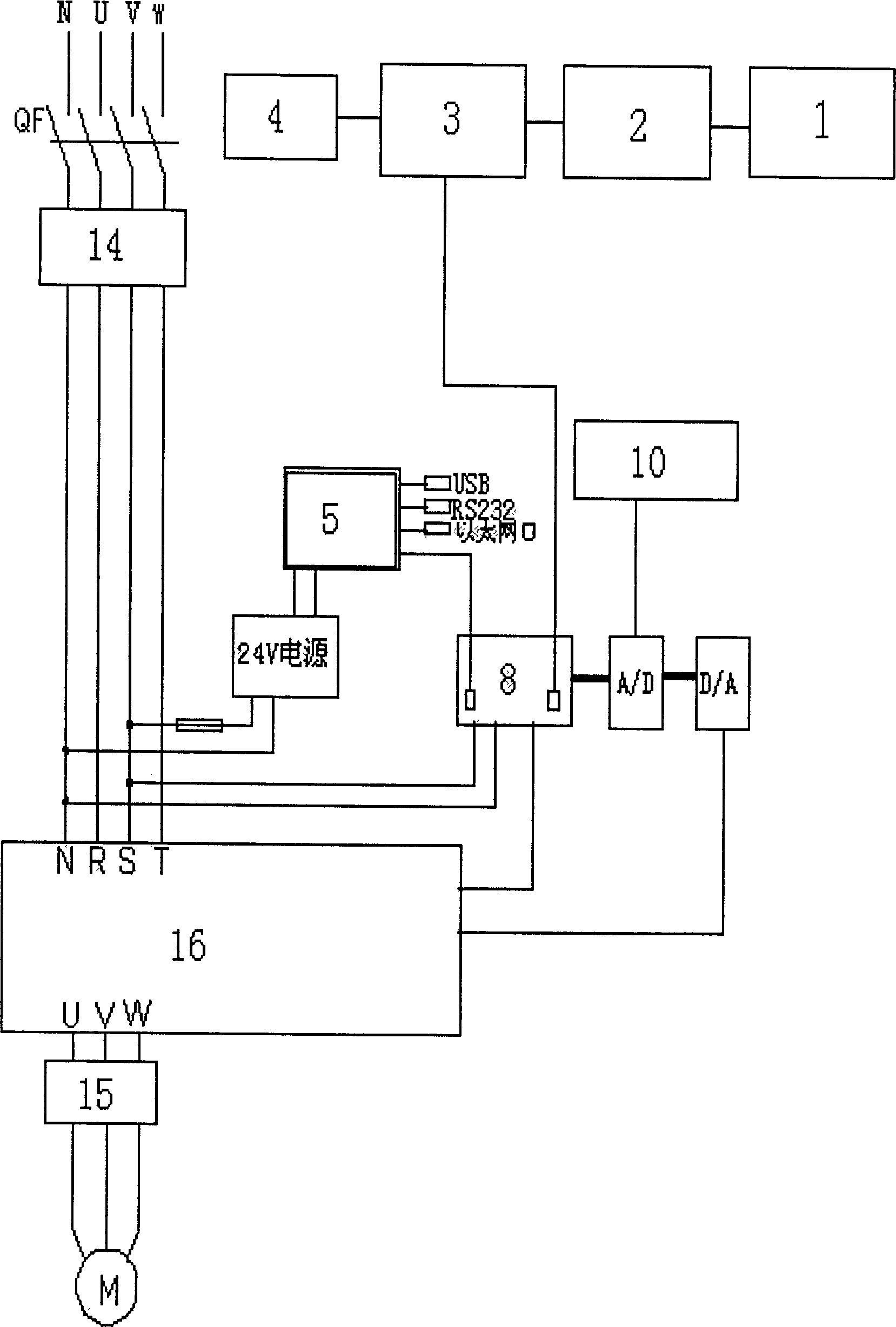

[0038] The structure of the present invention is as figure 1 , image 3 , Figure 4 and Figure 5 As shown, the control program flow chart is as follows figure 2 As shown, it includes a signal acquisition device 10, a power quality controller 11, a programmable controller 8, a visual operation device 5, a fuzzy controller 9, a workshop control station 3, an engineer control station 2 and an energy management station 1, and a signal acquisition device 10 It includes a data acquisition module and sensors for collecting temperature signals, humidity signals, pressure signals, flow signals, liquid level signals, wind speed signals and electric energy signals. The signal acquisition device 10 is connected to the corresponding sensor through a shielded cable. The signal acquisition device 10 and programmable The controller 8 is connected through the system bus, the power quality controller 11 is connected with the current transformer and the voltage output lines of phase A, B an...

Embodiment 2

[0062] Embodiment 2: The structure and energy-saving control program of the present invention are the same as Embodiment 1, the difference is that the frequency converter in the fuzzy control module adopts ABB ACS800 series.

Embodiment 3

[0063] Embodiment 3: The structure and energy-saving control program of the present invention are the same as Embodiment 1, the difference is that the frequency converter in the fuzzy control module adopts the NX series of Vulcan, Finland.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com