Indoor evaluation method for profile control and water shutoff technology using polymer microsphere

A technology for profile control and water plugging and indoor evaluation, which is used in earth-moving drilling, wellbore/well components, instruments, etc. Evaluation of properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

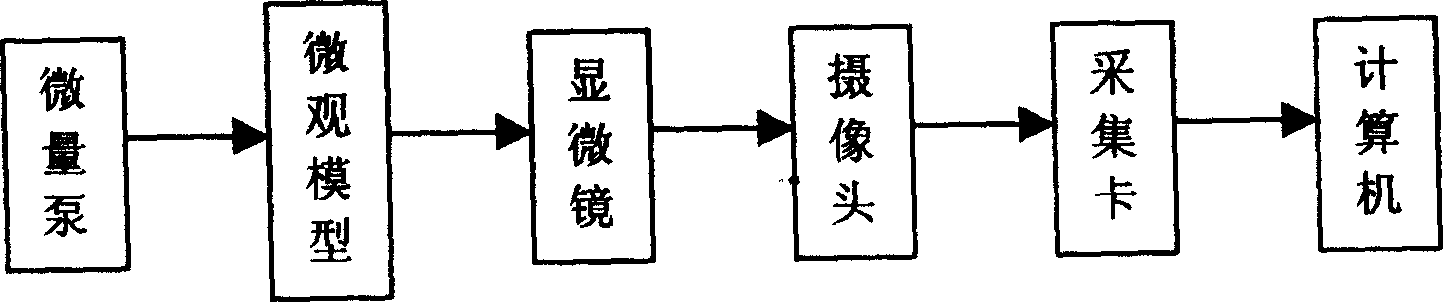

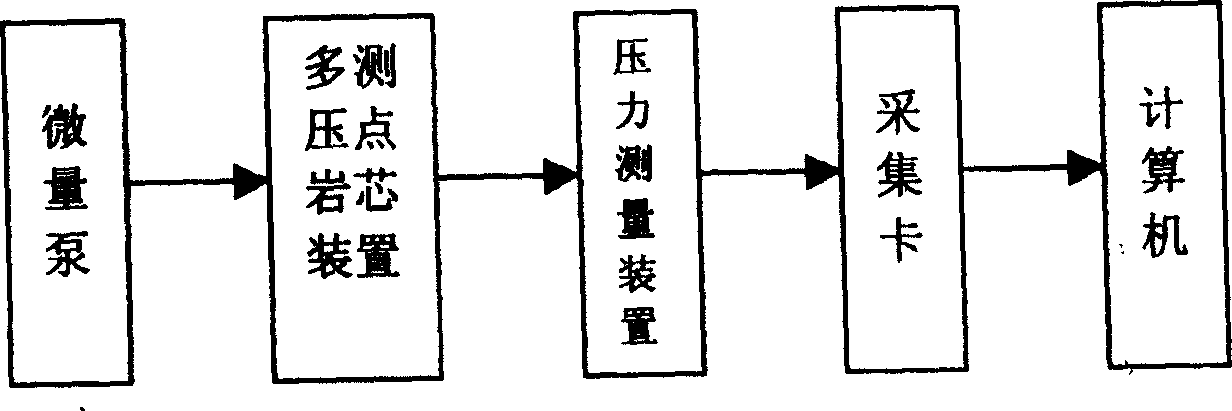

[0025] Embodiment 1 (as figure 1 shown)

[0026] Determination of the microscopic morphology of polymer microspheres: drop the pure aqueous solution of polymer microspheres with a concentration of 600ppm and swell at 60°C for 1 day on a thin glass slide with a dropper, and place it under a biological microscope with a magnification of 10,000 times On the screen, select the Daheng image acquisition card, start the corresponding video acquisition software to collect pictures, and collect a series of pictures, all of which are approximately regular spherical particles, as shown in Figure 3. After processing with a computer, the average particle size is determined to be 0.5 Micron; the solution expanded at 60°C for 7 days can also collect photos similar to those in Figure 3, and after computer processing, the average particle size is determined to be 4.5 microns. From this experiment, it can be confirmed that the shape of the microspheres is indeed spherical, and the expansion fa...

Embodiment 2

[0027] Embodiment 2 (as figure 1 shown)

[0028] Determination of the microscopic profile control mechanism of polymer microspheres: Etch a glass model with a pore volume of 0.02ml, and perform the process of vacuuming and saturating water according to the conventional method; then put the model under an optical microscope, turn on the computer, and start the video Program, select the magnification and focus on a pore throat with a diameter of 20 microns on the computer screen according to the conventional method; inject the polymer microsphere solution into the glass etching model at a pump speed of 0.001ml / min In the process, the plugging process of the microspheres at the pore throat was observed on the computer screen, and the video was continuously collected. Figure 4 shows the pore throat when no microspheres pass through, and Figure 5 shows four microspheres bridging and blocking the pore throat. There are many similar pictures. The microspheres are blocked at one por...

Embodiment 3

[0029] Embodiment 3 (as figure 1 shown)

[0030]The method of measuring the enhanced oil recovery of polymer microspheres in the microscopic model: the glass etching model with a pore volume of 0.016ml is vacuumized and saturated with water according to the conventional method; then the model is saturated with oil according to the conventional method. Then put the model under the stereo microscope, turn on the computer, start the video program, and select the magnification and focus on the computer screen according to the conventional method; The etching model was flooded with water for 20 minutes, then flooded with 600 ppm polymer microsphere solution for 8 minutes, and then flooded with water for 40 minutes. Finally, the collected video pictures were processed through the picture program, and the water flooding recovery rate was calculated to be 50%. After injecting the microsphere emulsion, the final recovery rate was 71%, and the recovery rate increased by 21%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com